Accelerated stream cooling device cooling technique integration method

A technology for accelerating laminar cooling and cooling process, which is applied in the field of laminar cooling of steel plates, can solve the problems of steel plates fluttering and steel plates prone to buckling, and achieve the effect of reducing tracking errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

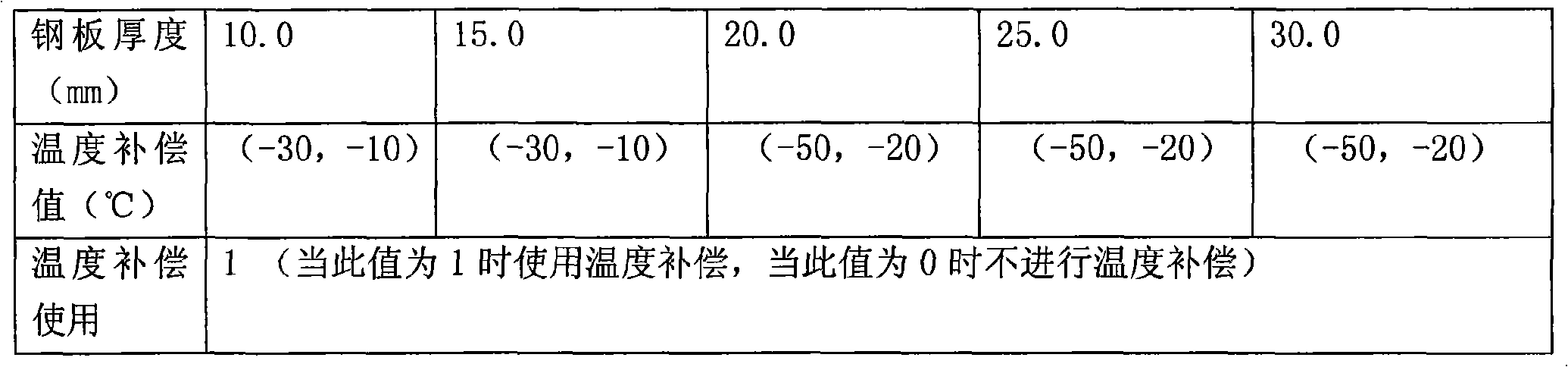

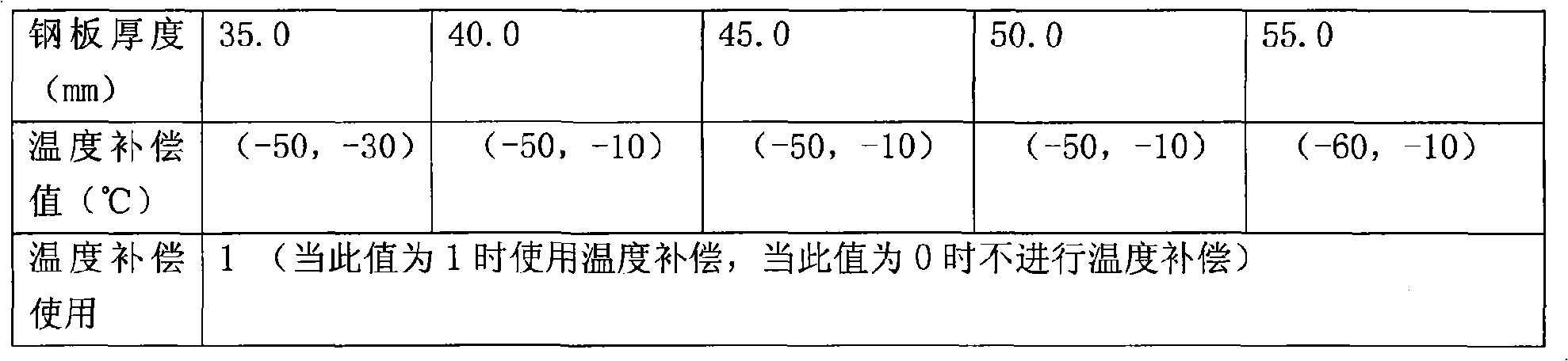

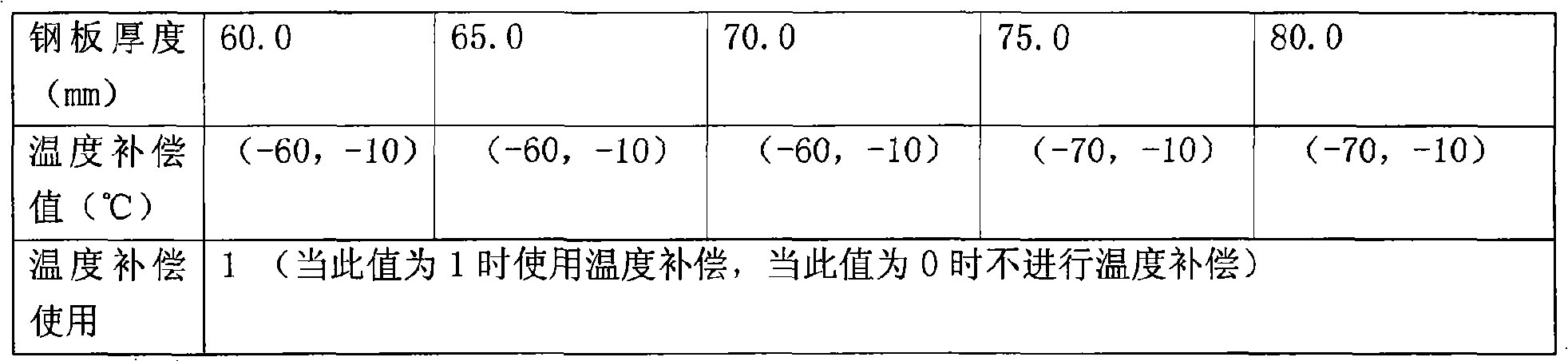

[0022] In order to improve the final cooling temperature and cooling speed hit rate, we establish temperature compensation functions for steel plates with different thickness specifications, and calculate the error law between the final rolling temperature issued by Siemens and the ACC inlet detection temperature of different thickness specifications, and calculate the final rolling temperature through the interface file. Compensation reduces the amount of online adjustment and improves the final cooling temperature and cooling speed hit rate.

[0023] 5. Because the rolling mill operators intervened in the rolling, the messages sent to ACC by some rolling mills were lost and the steel plate could not be cooled. By optimizing the program and reducing the restrictive conditions, the steel plate can be tracked and cooled more stably and accurately.

[0024] Table 1 shows the ratio value of the water flow of the upper and lower headers of ACC according to the thickness of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com