Electrolytic manganese dioxide, and method for its production and its application

A technology for electrolytic manganese dioxide and a manufacturing method, which is applied to electrolytic components, electrolytic processes, circuits, etc., can solve the problems of reduced utilization rate, short time, and inability to fully utilize manganese dioxide, and achieve stable manufacturing, alkaline potential and other problems. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

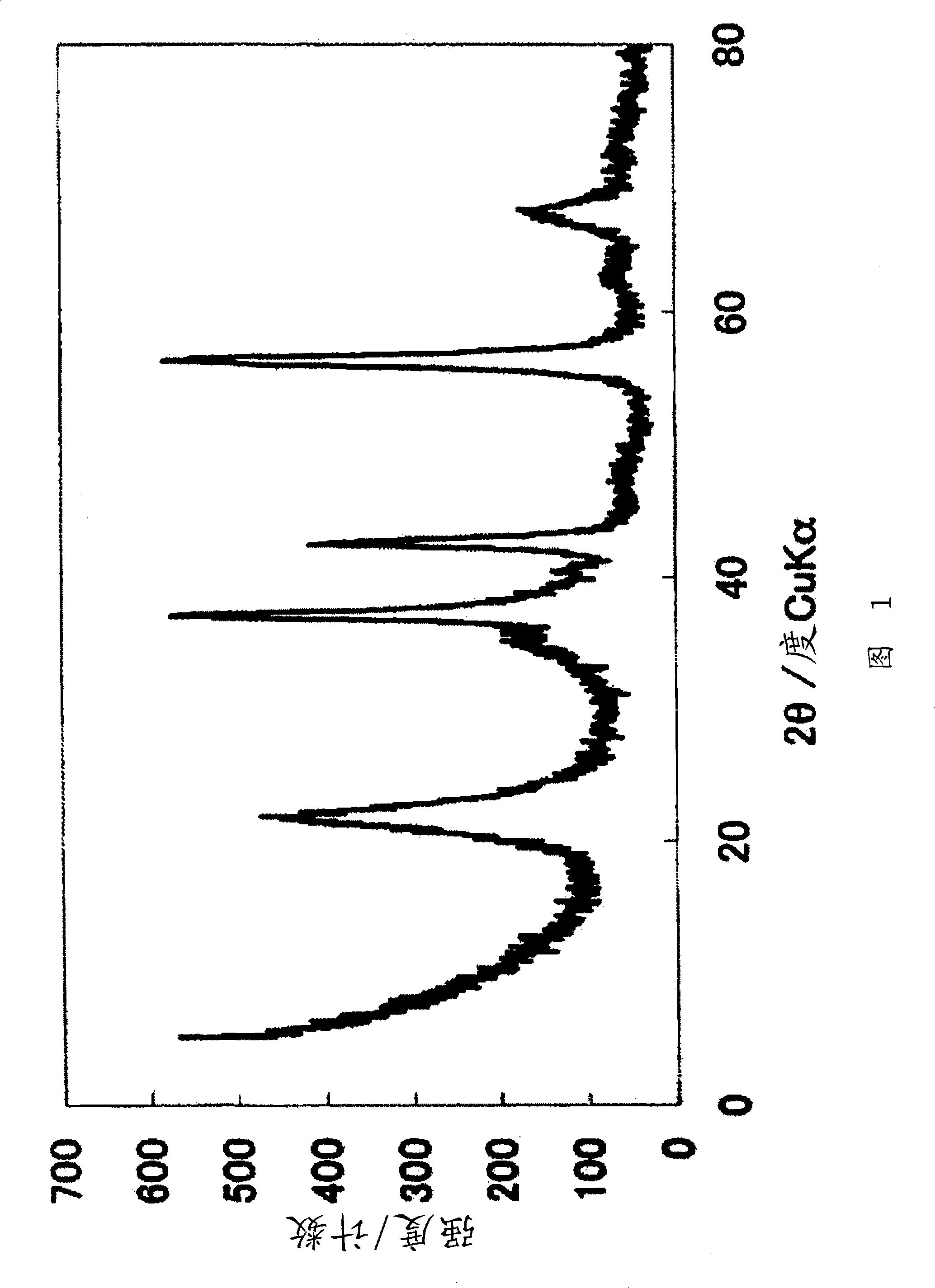

[0093] The current density is 0.5A / dm 2 , The electrolysis temperature is 96°C, the electrolysis replenishment liquid is a manganese sulfate solution with a manganese concentration of 50.0g / l, the sulfuric acid concentrations in the initial stage of electrolysis and the second half of electrolysis are 29.2g / l and 74.8g / l respectively, and it is carried out like this for 16 days electrolysis. Electrolysis was performed for 13 days at the concentration of the first half range, and electrolysis was performed for 3 days at the concentration of the second half range. Table 1 shows the physical properties and battery characteristics of the obtained manganese dioxide.

Embodiment 2

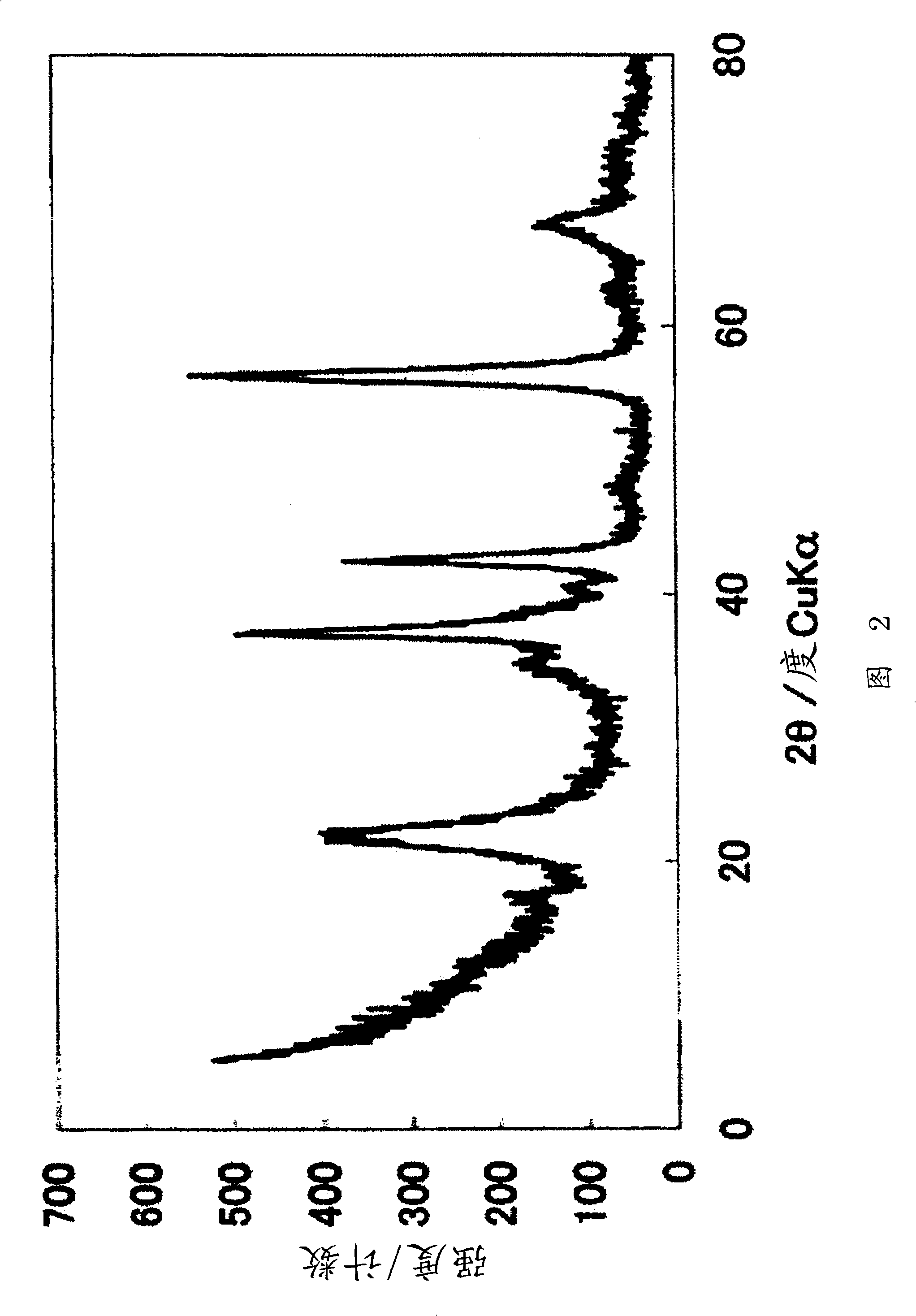

[0095] The current density is 0.5A / dm 2 , The electrolysis temperature is 96°C, the electrolysis replenishment liquid is a manganese sulfate solution with a manganese concentration of 40.0g / l, the sulfuric acid concentrations in the initial stage of electrolysis and the second half of electrolysis are 29.2g / l and 49.2g / l respectively, and it is carried out like this for 14 days electrolysis. Electrolysis was performed for 10 days at the concentration of the first half range, and electrolysis was performed for 4 days at the concentration of the second half range.

Embodiment 3

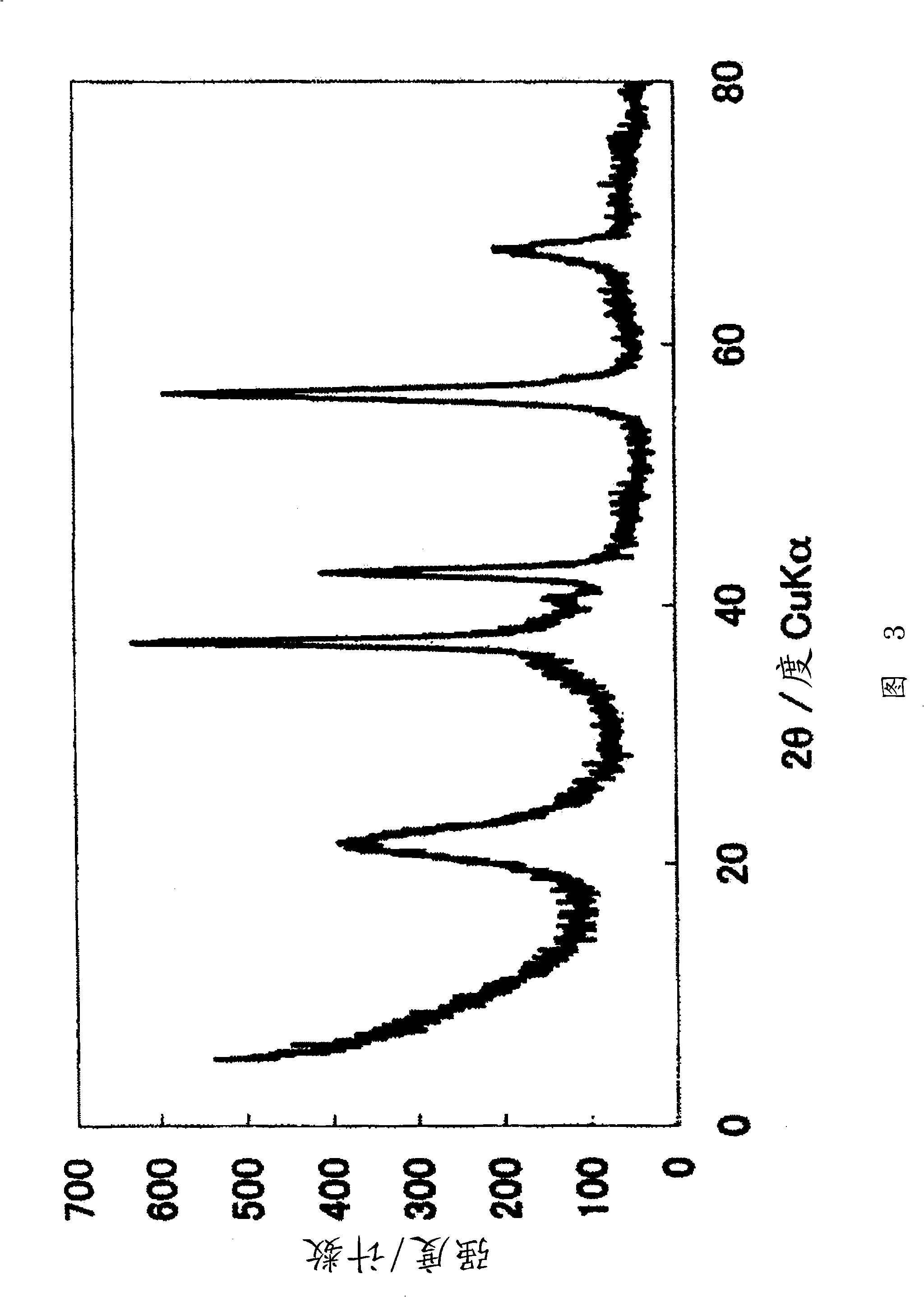

[0097] Except that the sulfuric acid concentration in the electrolytic solution in the first 12 days of electrolysis is 29.2g / l, and the sulfuric acid concentration in the electrolytic solution in the latter 2 days of electrolysis is 44.7g / l, obtain electrolytic dioxide by the same method as Example 2 manganese.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com