Long life spiral transduction apparatus

A helical and long-life technology, applied in mechanical equipment, drilling equipment, rotary piston pumps, etc., can solve problems such as volumetric efficiency reduction, rotor, stator wear, loss of working ability, etc., to reduce starting resistance, prolong service life, The effect of high volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

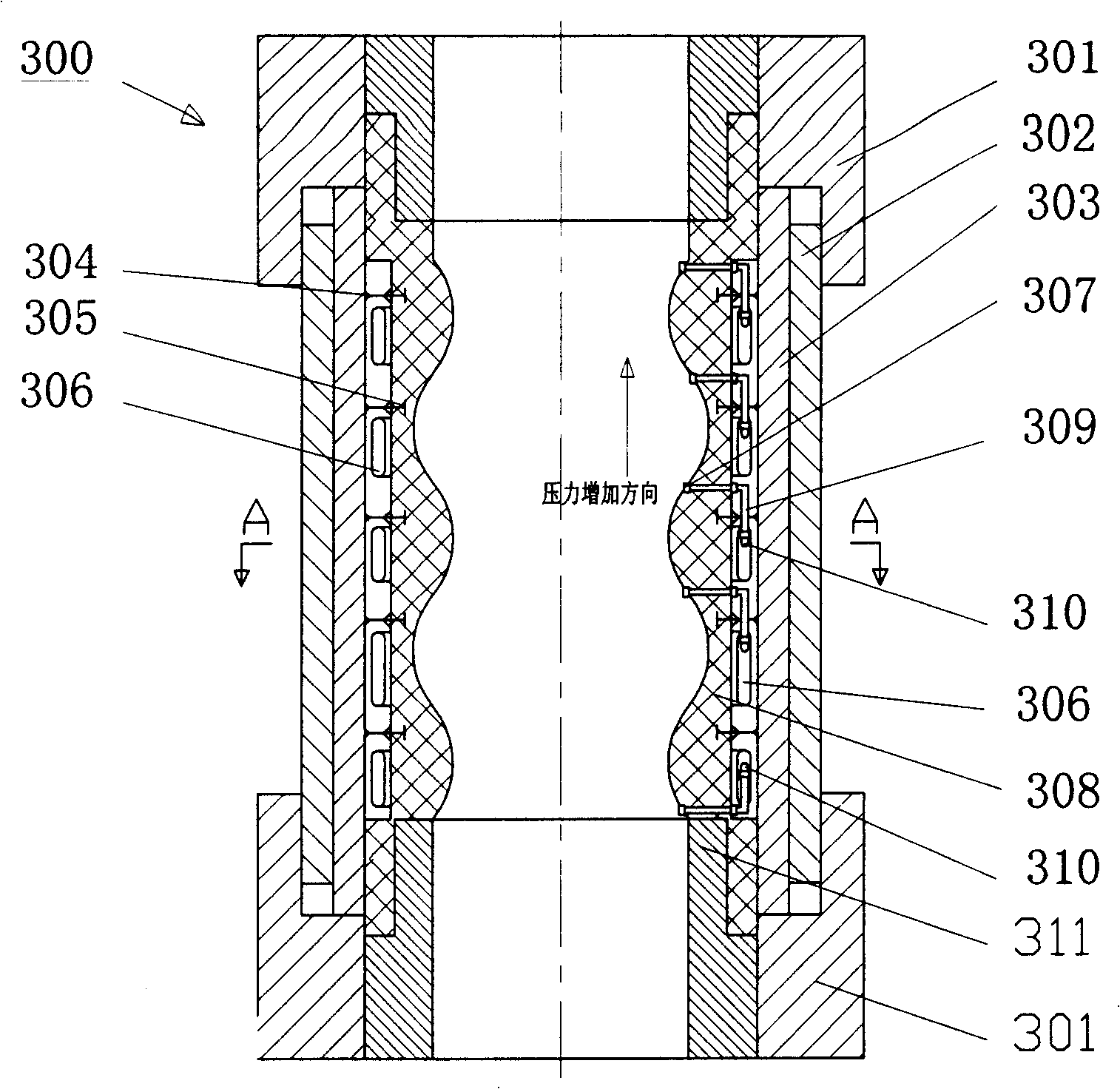

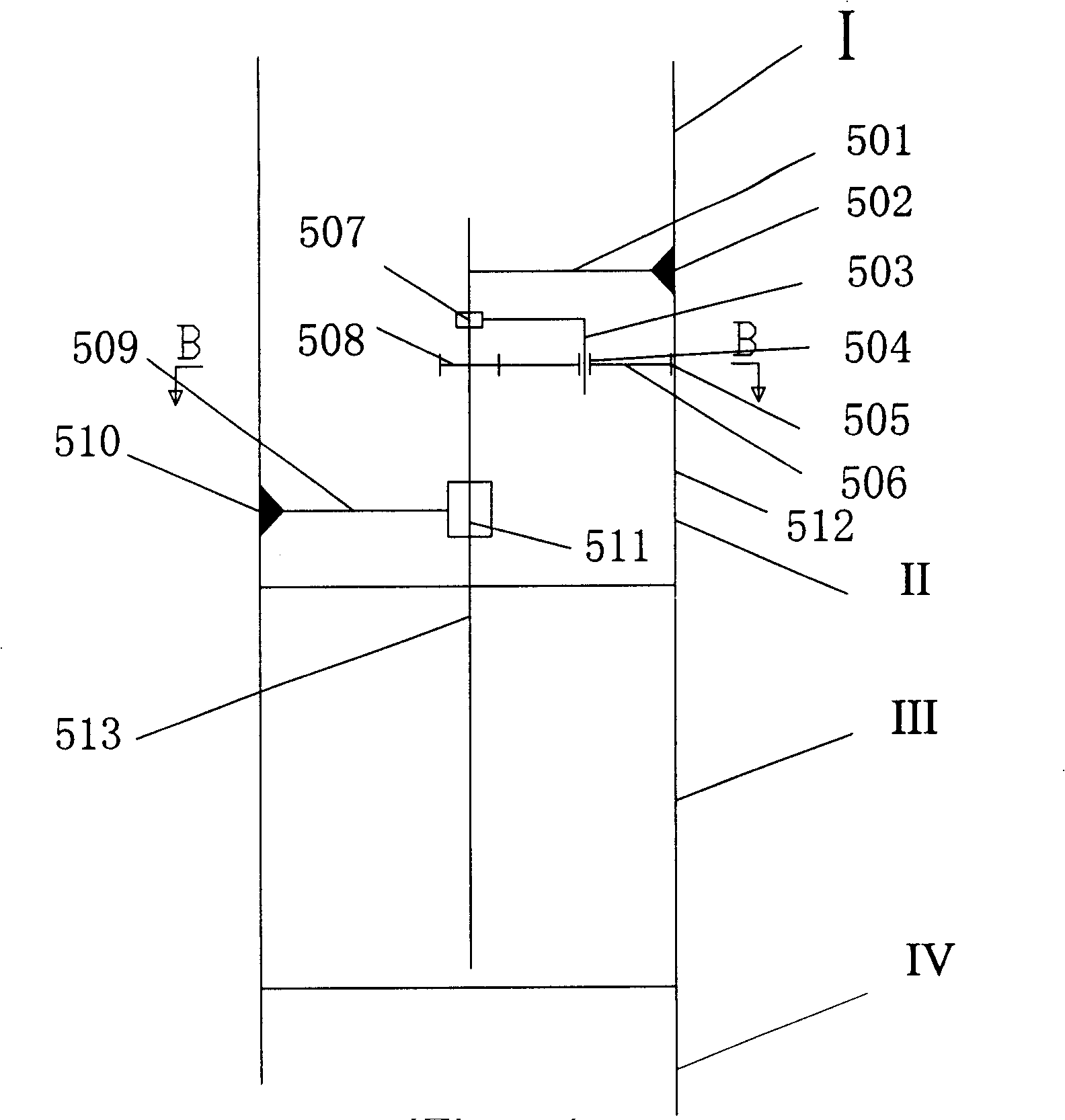

[0039] Such as Figure 5 , 5a As shown, the long-life spiral transducing device provided by the present invention includes a stator 300 and a rotor (not shown in this figure),

[0040] The rotor is a single-head or multi-head spiral steel shaft;

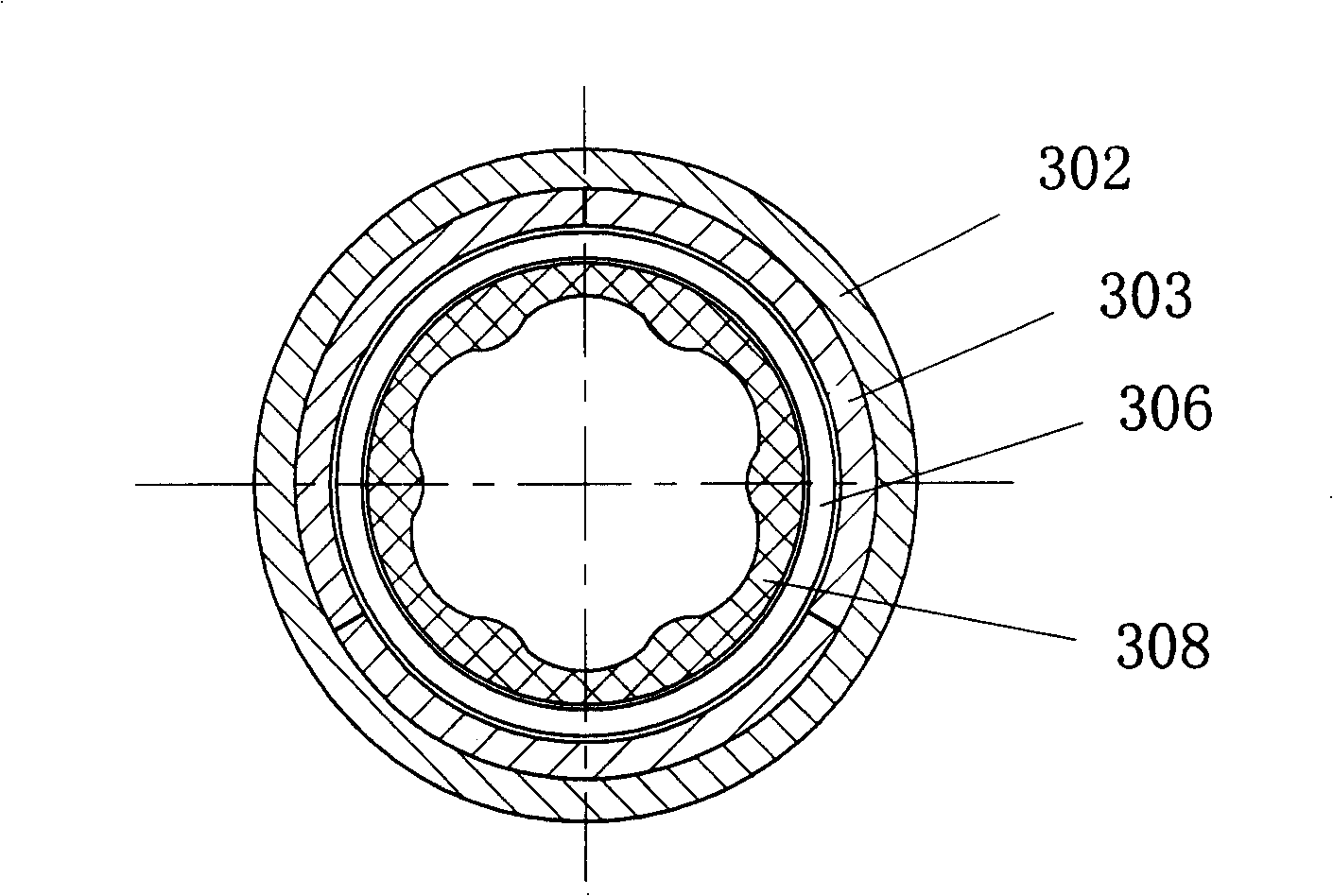

[0041] The stator 300 includes an outer cylinder, the outer cylinder includes a shell 302 and a split inner cylinder 303, the split inner cylinder 303 is divided into three equal parts in the circumferential direction, and also includes a soft elastic The elastic stator rubber core 308 made of material, the outer wall of the stator rubber core 308 is a cylindrical shape matching the cavity shape of the split inner tube 303, and the inner wall of the stator rubber core 308 is a double-headed or multi-headed In the spiral chamber, the number of stator spiral heads is always 1 greater than the number of rotor spiral heads. Usually, the number of stator and rotor spiral heads is an odd number, and the number of stator spiral heads is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com