Process for determining thermoconductivity

A technology of thermal conductivity and heating rate, which is applied in the field of instrument analysis, can solve the problems of inconvenient testing work, single function of instruments and equipment, complex calculation formulas, etc., and achieve the effect of fast and accurate thermal conductivity and fast and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1 measures the thermal conductivity of aluminum (the thermal conductivity of known aluminum is 238W.m -1 .K -1 ).

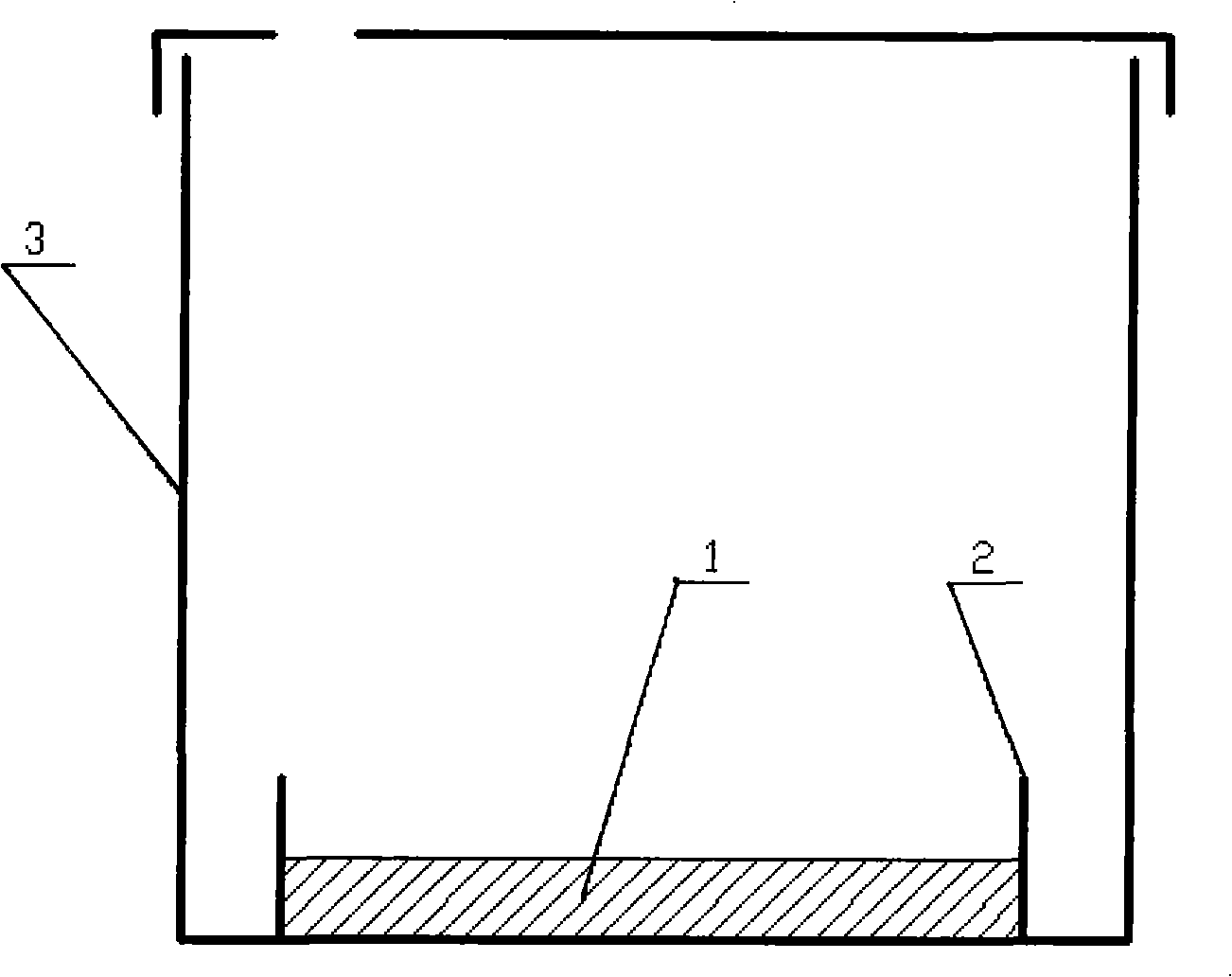

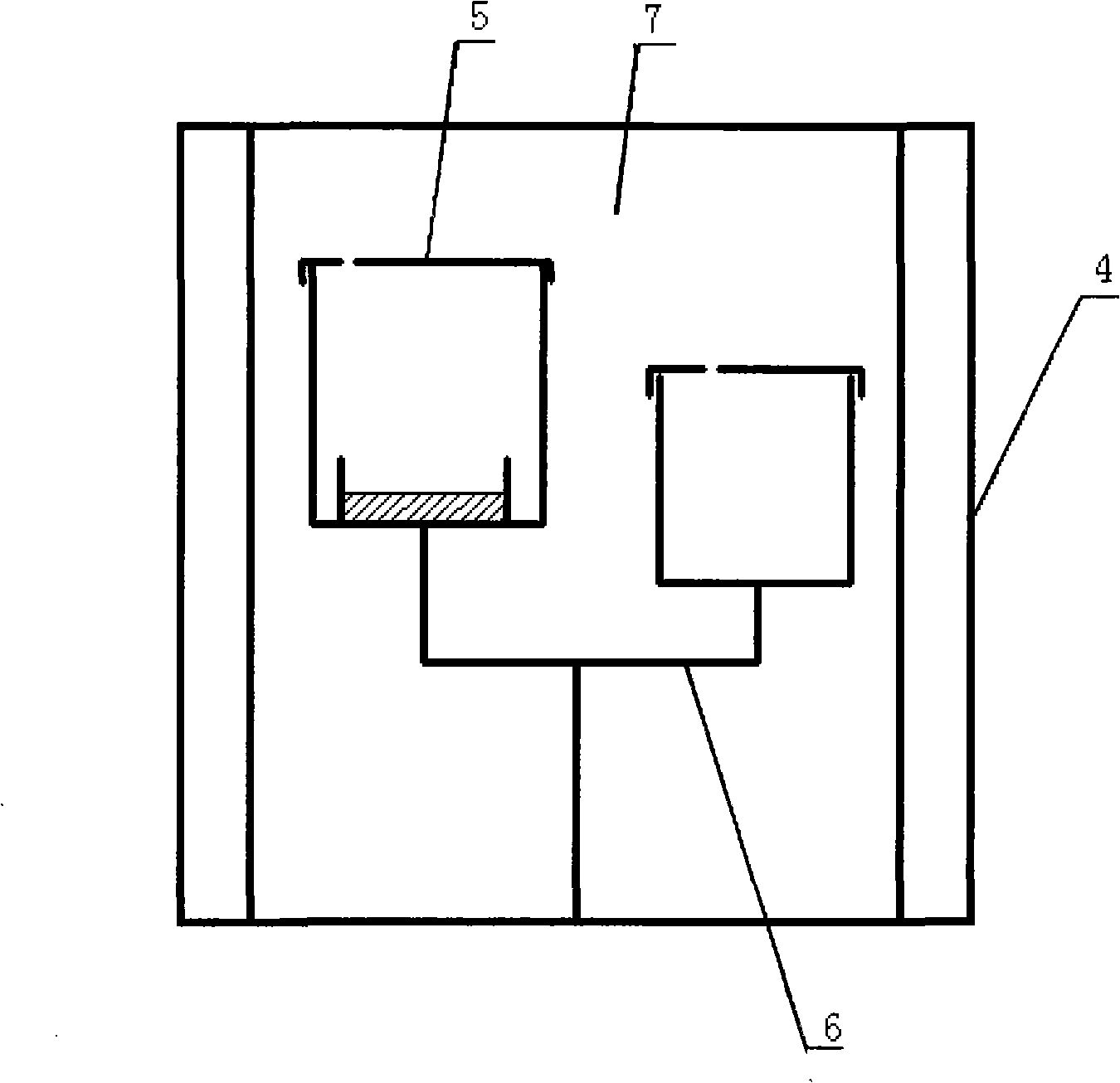

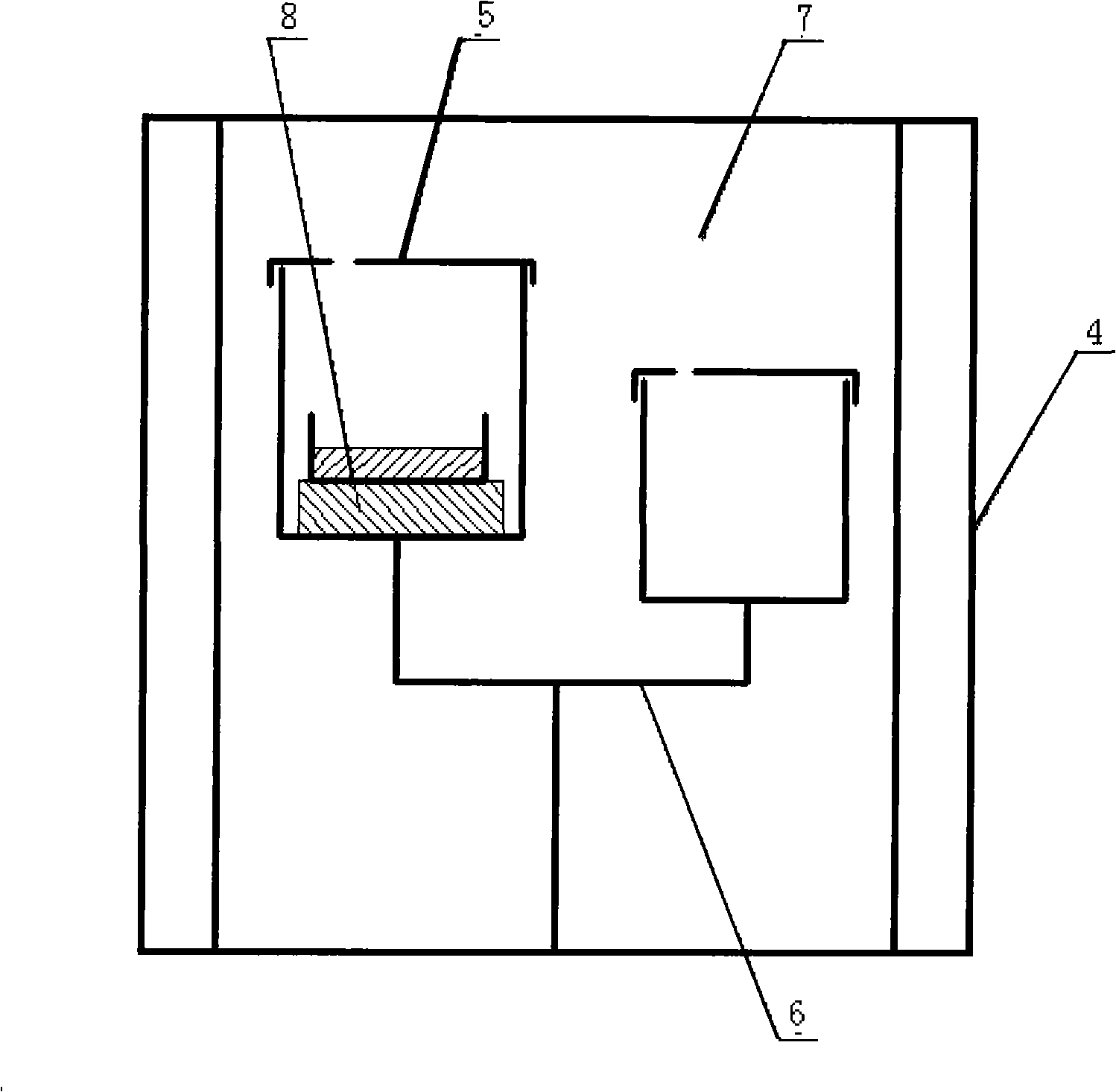

[0078] A small piece of indium is selected as the standard sample, and the standard sample is tested together with the platinum crucible. The DSC test uses a vacuum atmosphere, the temperature range is 300K to 480K, and the heating rate is 0.0833K / s. The model of the differential scanning calorimeter we choose is For the NETZSCH synchronous thermal analyzer STA449C, the DSC curve related to thermal conductivity is in the temperature range from 400K to 470K, and a DSC curve is obtained through the test, as shown in Figure 6.

[0079] Then make the aluminum block of the sample to be tested into H=3.13mm, and the cross-sectional area S=2.98mm 2 The column is placed between the platinum crucible with the standard sample and the instrument crucible, and the DSC test of the aluminum block sample is carried out under the same conditions as the standa...

Embodiment 2

[0086] Embodiment 2 measures the thermal conductivity of aluminum (the thermal conductivity of known aluminum is 238W.m -1 .K -1 ).

[0087] A small piece of indium is selected as the standard sample, and the standard sample is tested together with the platinum crucible. The DSC test uses a vacuum atmosphere, the temperature range is 300K to 480K, and the heating rate is 0.167K / s. The model of the differential scanning calorimeter we choose is It is a NETZSCH synchronous thermal analyzer STA449C, the DSC curve related to thermal conductivity is in the temperature range from 400K to 470K, and a DSC curve A is obtained through the test, as shown in Figure 8.

[0088] Then make the aluminum block of the sample to be tested into H=3.13mm, and the cross-sectional area S=2.98mm 2 The column is placed between the platinum crucible with the standard sample and the instrument crucible, and the DSC test of the aluminum block sample is carried out under the same conditions as the test ...

Embodiment 3

[0095] Embodiment 3 measures the thermal conductivity of brass (the thermal conductivity of known brass is 10 W.m -1 .K -1 ).

[0096] A small piece of indium is selected as the standard sample, and the standard sample is tested together with the platinum crucible. The DSC test uses a vacuum atmosphere, the temperature range is 300K to 480K, and the heating rate is 0.0833K / s. The model of the differential scanning calorimeter we choose is For the NETZSCH synchronous thermal analyzer STA449C, the DSC curve related to the thermal conductivity is in the temperature range from 400K to 470K, and a DSC curve C is obtained from the test, as shown in Figure 9.

[0097] Then the brass sample to be tested is made into a certain shape, the sample to be tested is H=3.13mm, and the cross-sectional area S=2.98mm 2 The column is placed between the platinum crucible with the standard sample and the instrument crucible, and the DSC test of the brass sample is carried out under the same condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com