Liquid crystal display panel and its array substrate

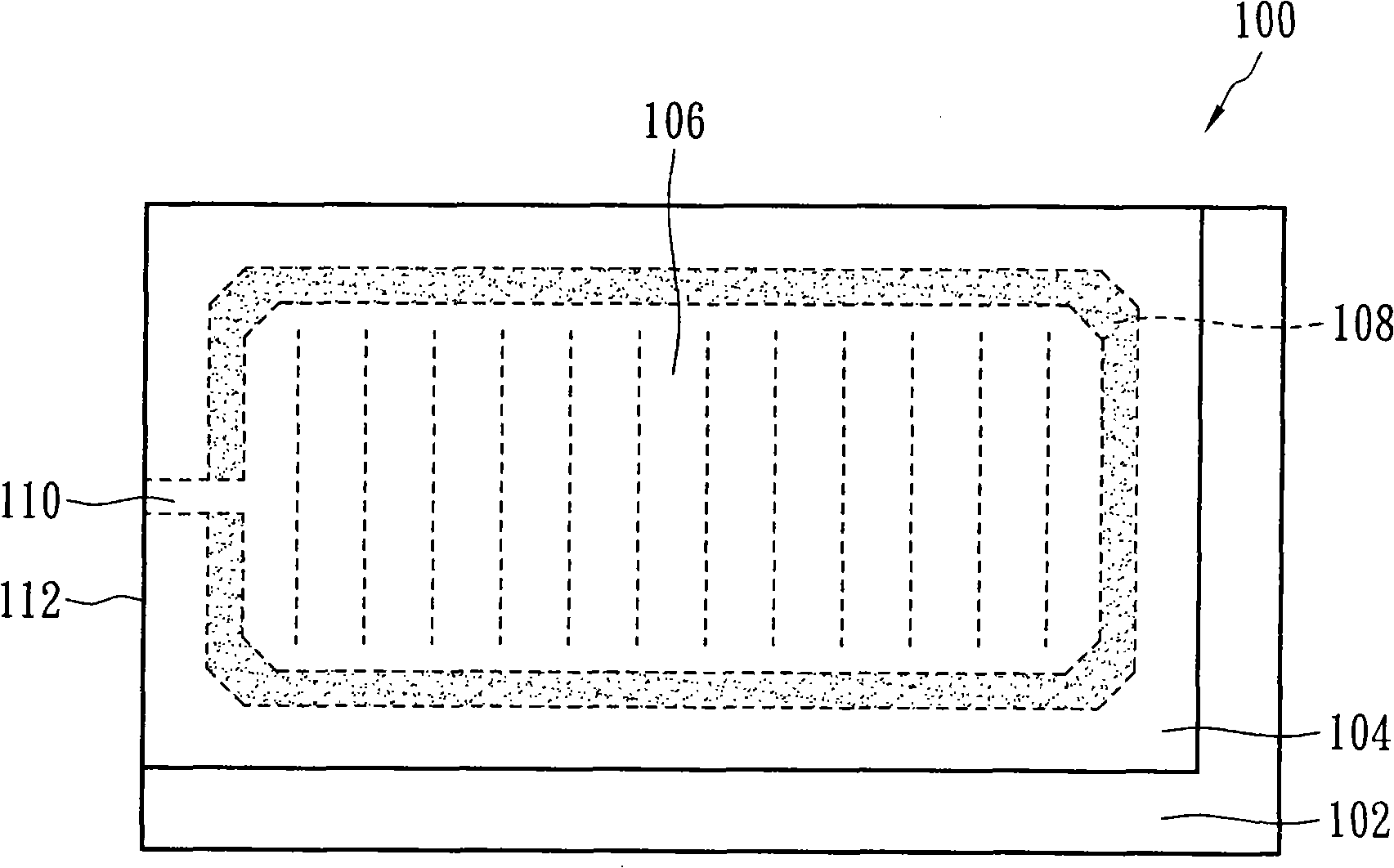

A technology of liquid crystal display panels and array substrates, applied in nonlinear optics, instruments, optics, etc., which can solve the problems of glued liquid crystal injection port frame, limited pen closing form, missing corners and damage, missing corners and fragments, etc. Achieve the effect of avoiding bad cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The making and using of the presently preferred embodiments described are discussed in detail below. It should be appreciated, however, that the present invention provides many applicable inventive concepts, which can be embodied in a wide variety of specific situations. The specific examples discussed are merely illustrative of specific ways to make and use the described invention, and do not limit the scope of the invention.

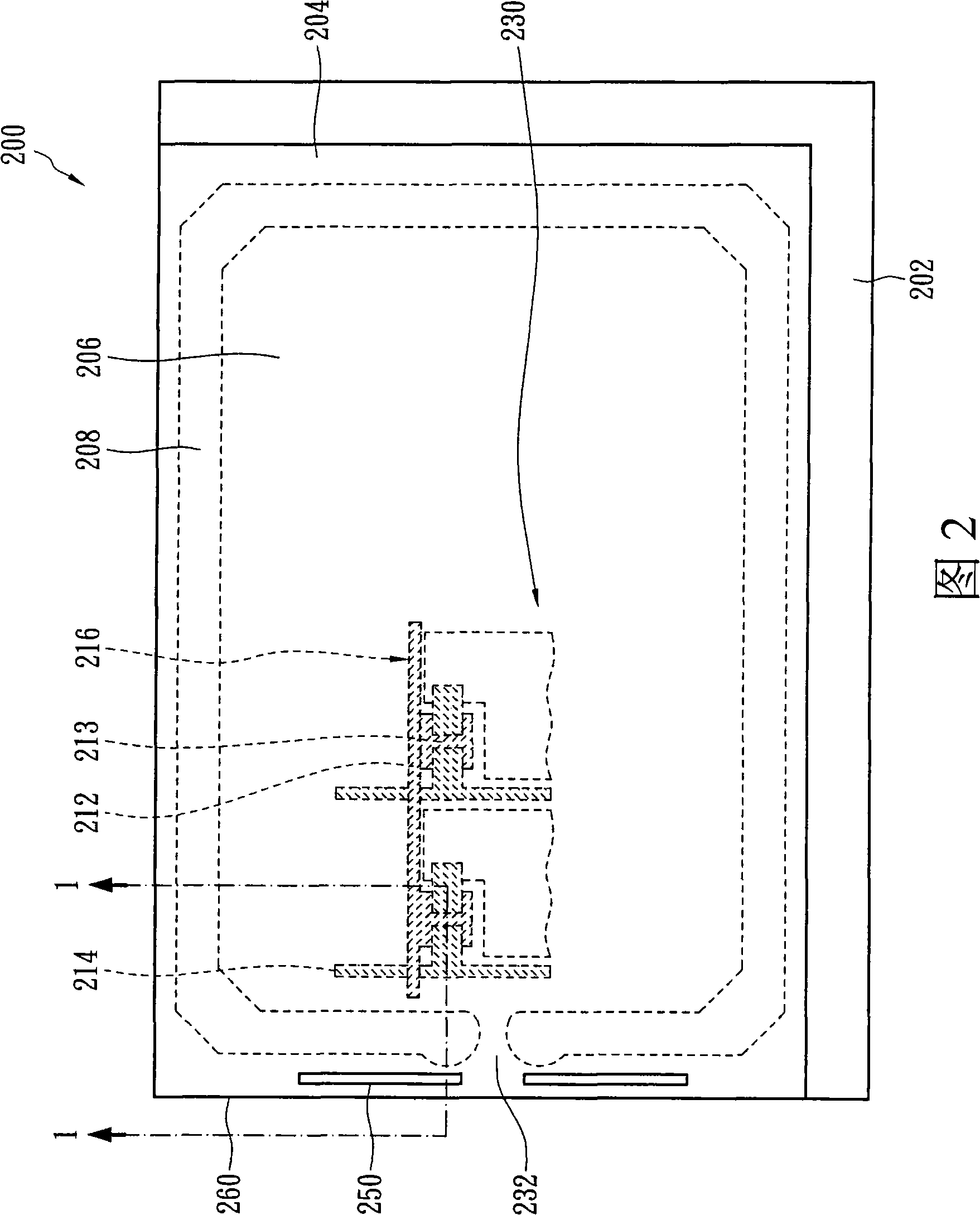

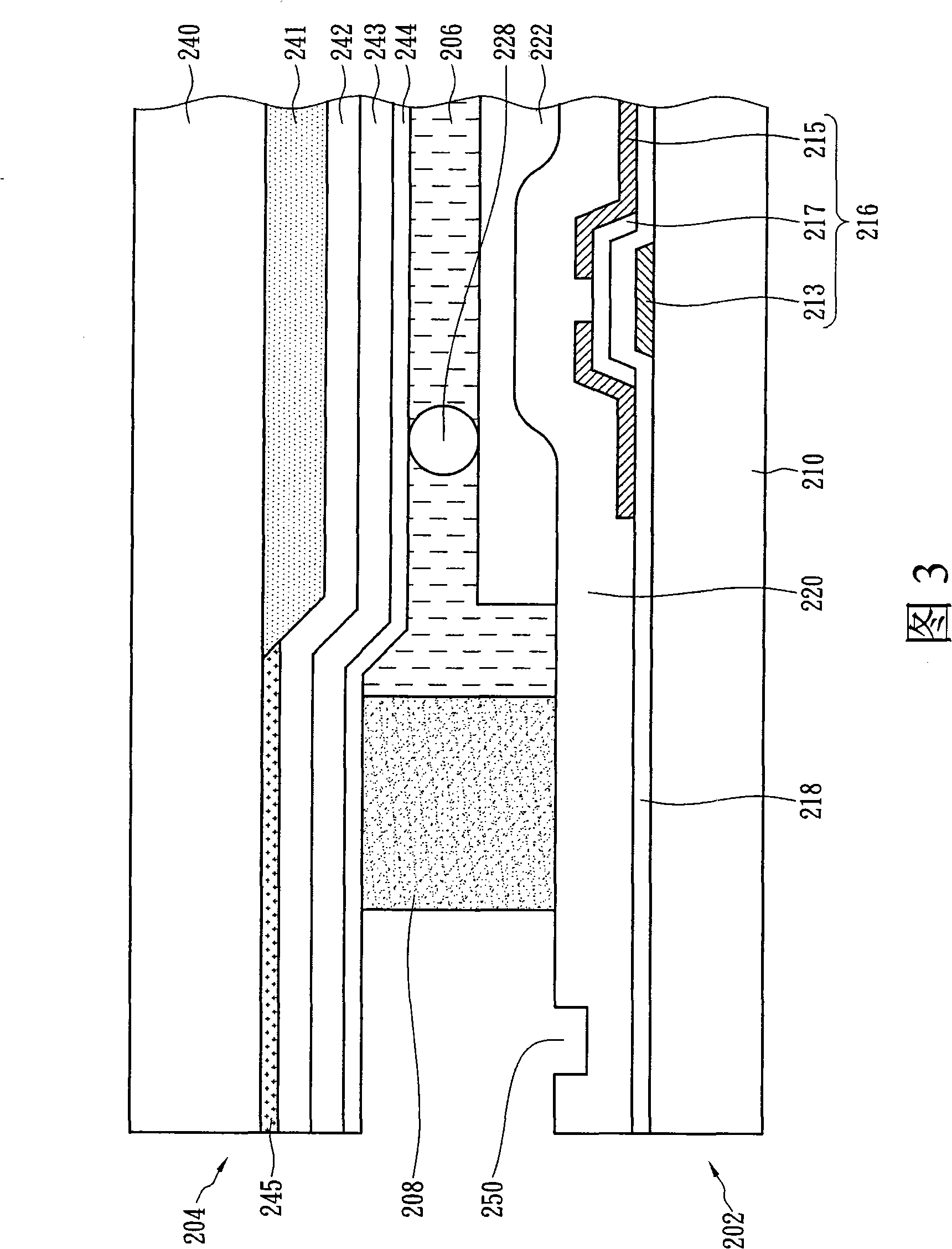

[0053] FIG. 2 shows a liquid crystal display panel 200 according to an embodiment of the present invention, and FIG. 3 is a schematic cross-sectional view of the first embodiment along the line 1-1 in FIG. 2 . The liquid crystal display panel 200 mainly includes a thin film transistor array substrate 202 , a color filter array substrate 204 , a sealant 208 , and a liquid crystal layer 206 injected into the space formed by the aforementioned three through a liquid crystal injection port 232 .

[0054] The thin film transistor array substrate 202...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com