Bus-bar unit connecting device

A technology of unit connection and busbar, which is applied in the direction of cooling busbar device, busbar installation, electrical components, etc., can solve the problems of system insulation resistance drop, heat accumulation, temperature rise, etc., achieve convenient installation process, improve overload capacity and reduce contact The effect of resistance

Inactive Publication Date: 2008-11-19

JIANGSU SUCCESS ELECTRIC

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, the insulation partition is made of BMC material. Due to the limitation of the material performance (with strong water absorption): after the installation of the entire busbar system in the field, it is inevitable that the insulation resistance of the entire system will decrease, which will affect the system. Hidden dangers in safe operation

The partition between the bus phase line and the phase line adopts a single insulating partition. The insulating partition is a poor conductor of heat, which causes heat accumulation in the bus joints, high temperature rise, and reduces the overload capacity of the bus conductors.

The whole set of connection device has no limit device when the busbar is connected, the docking error between units cannot be grasped, and the bolt pre-tightening force cannot be controlled at the same time, resulting in arbitrarily large fastening state of the connection device, which is not conducive to long-term load operation of the system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

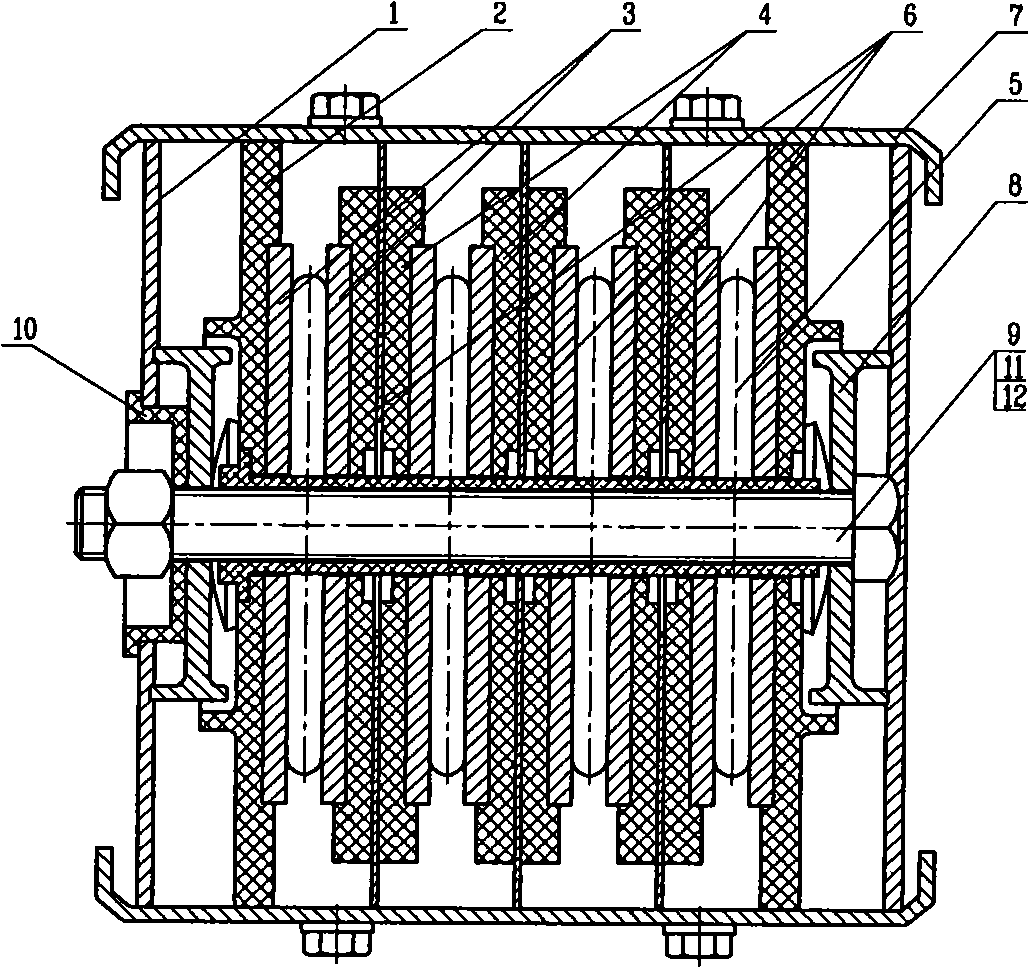

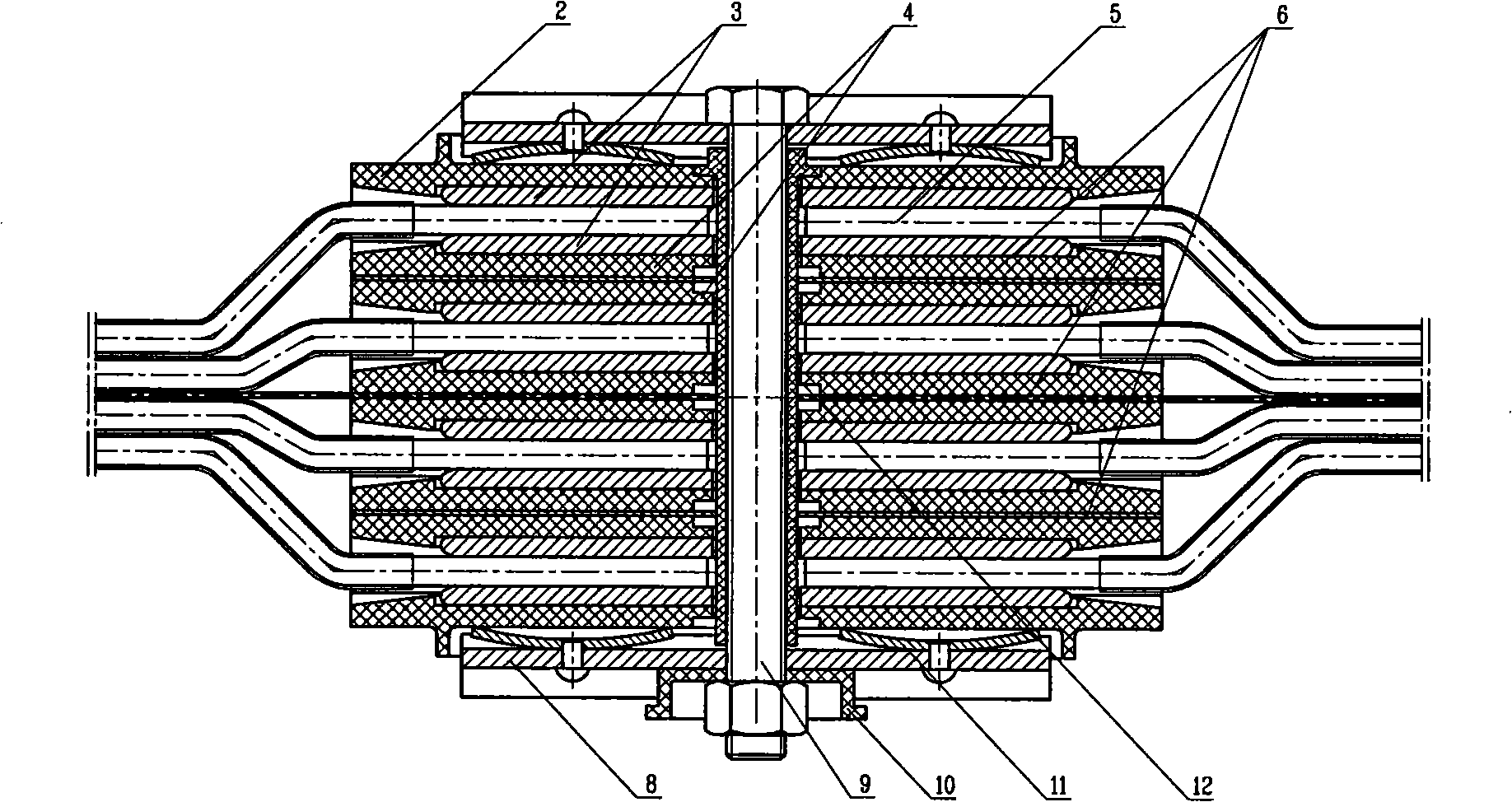

Login to View More Abstract

The invention relates to a busway unit connecting device which is used for connecting the compact busway trough units. The device is structured into a connector assembly by two insulated clapboards 1, eight conductive connecting plates, six insulated clapboards 2, three connector heat dissipation slices, a connector press plate, a connector sleeve pipe, a disk spring, a insulated sleeve pipe and a four-phase busway trough bar. As showed in the figure, the two insulated clapboards 1, the six insulated clapboards 2 and the eight conductive connecting plates clamp the four-phase busway trough bar by groups; the two insulated clapboards 1 are arranged at the furthest outside of the connector assembly. The middle parts of the insulated clapboards 1, the conductive connecting plates, the insulated clapboards 2, the connector heat dissipation slices and the connector press plate are all provided with connecting holes; a bolt connection pair with external hexagonal angles is invaginated into the insulated sleeve and then perforates the connecting holes and is nested by the connector press plate and the connector sleeve pipe; the connector press plate is tightly pressed after the nut is fastened. A protection cover is formed by two up and bottom connector cover plates and two left and right connector side plates at the periphery of the connector assembly.

Description

Bus unit connection device technical field The invention relates to a connection device for busbar units. Background technique In the prior art, the insulation partition is made of BMC material. Due to the limitation of the material performance (with strong water absorption): after the installation of the entire busbar system in the field, it is inevitable that the insulation resistance of the entire system will decrease, which will affect the system. Safe operation brings hidden dangers. The partition between the bus phase line and the phase line adopts a single insulating partition. The insulating partition is a poor conductor of heat, which will cause heat accumulation in the bus joint, high temperature rise, and reduce the overload capacity of the bus conductor. The whole set of connection device has no limit device when connecting the busbar, the docking error between units cannot be grasped, and the bolt pre-tightening force cannot be controlled at the same time, re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02G5/00H02G5/10

Inventor 郭道鹏赵金勇莫寒何世阳江华张天宝

Owner JIANGSU SUCCESS ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com