One-master-driving-two system of industrial frequency transformer realized on basis of digital signal processor (DSP)

A digital signal and processor technology, applied in control systems, electrical components, control of multiple AC motors, etc., can solve the problems of unfavorable mass production and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, implementation modes of the present invention will be described with reference to the drawings.

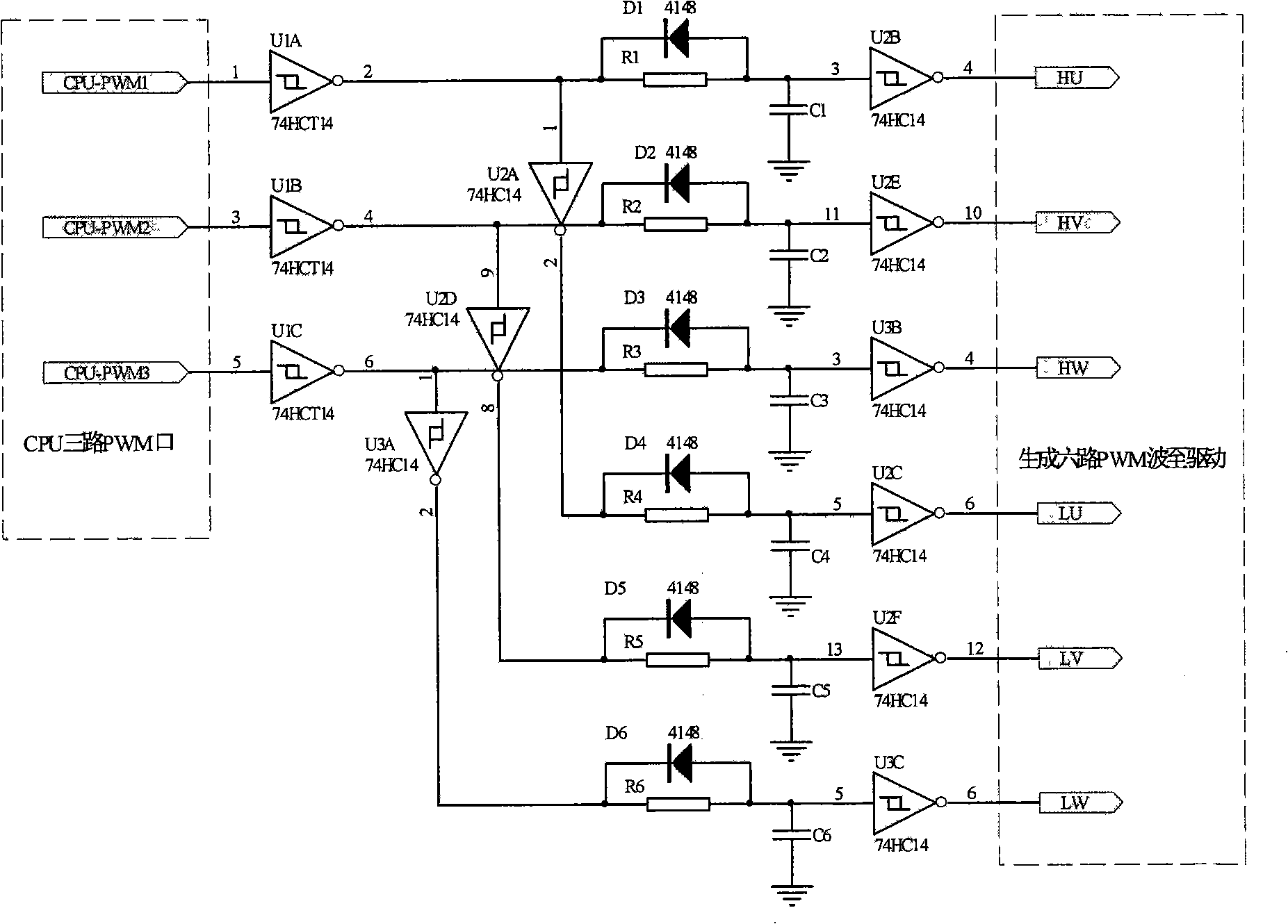

[0017] The digital signal processor (DSP) that the present invention adopts is TMS320F28015PZAPZA, and this DSP itself has six PWM generation ports, and each PWM port can arbitrarily generate required PWM waves. Through the three PWM ports, six channels of PWM waves can be generated by connecting peripheral hardware circuits, thereby generating 12 channels of PWM waves required to control two three-phase asynchronous motors at the same time.

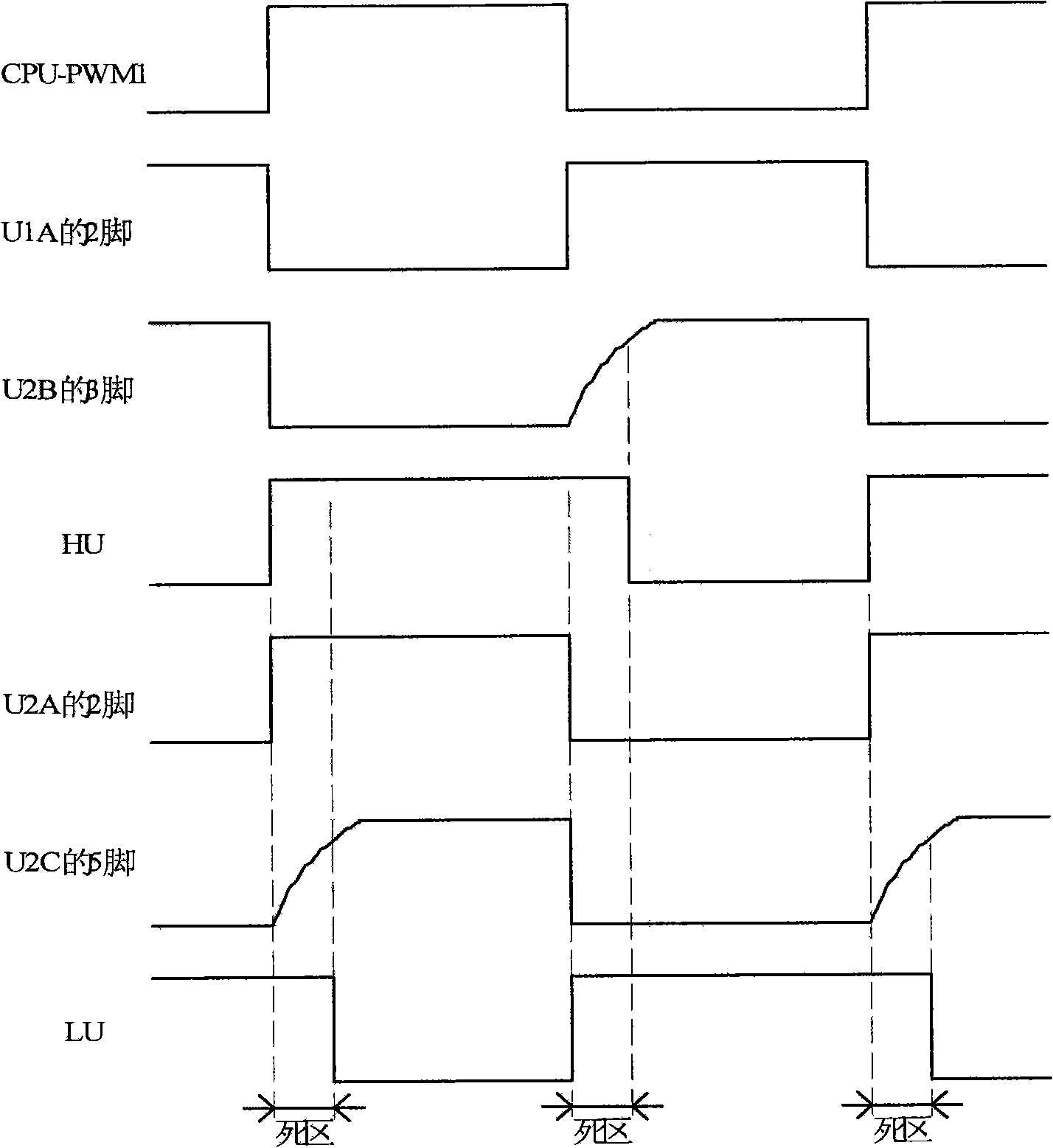

[0018] An inverter generally has 6 switching devices, and each phase output occupies 2 switching devices, which are called the upper bridge and the lower bridge of the corresponding phase, and the 3-phase output occupies a total of 6 switching devices. At the same time, the upper bridge and the lower bridge cannot be turned on at the same time. In the circuit, the transmission of the signal has a certain delay. As a resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com