AC plasma ejecting gun

A technology of launching gun and plasma, applied in the field of ion launching gun, can solve problems such as unmanned application of AC plasma, and achieve the effect of ensuring service life, improving service life and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

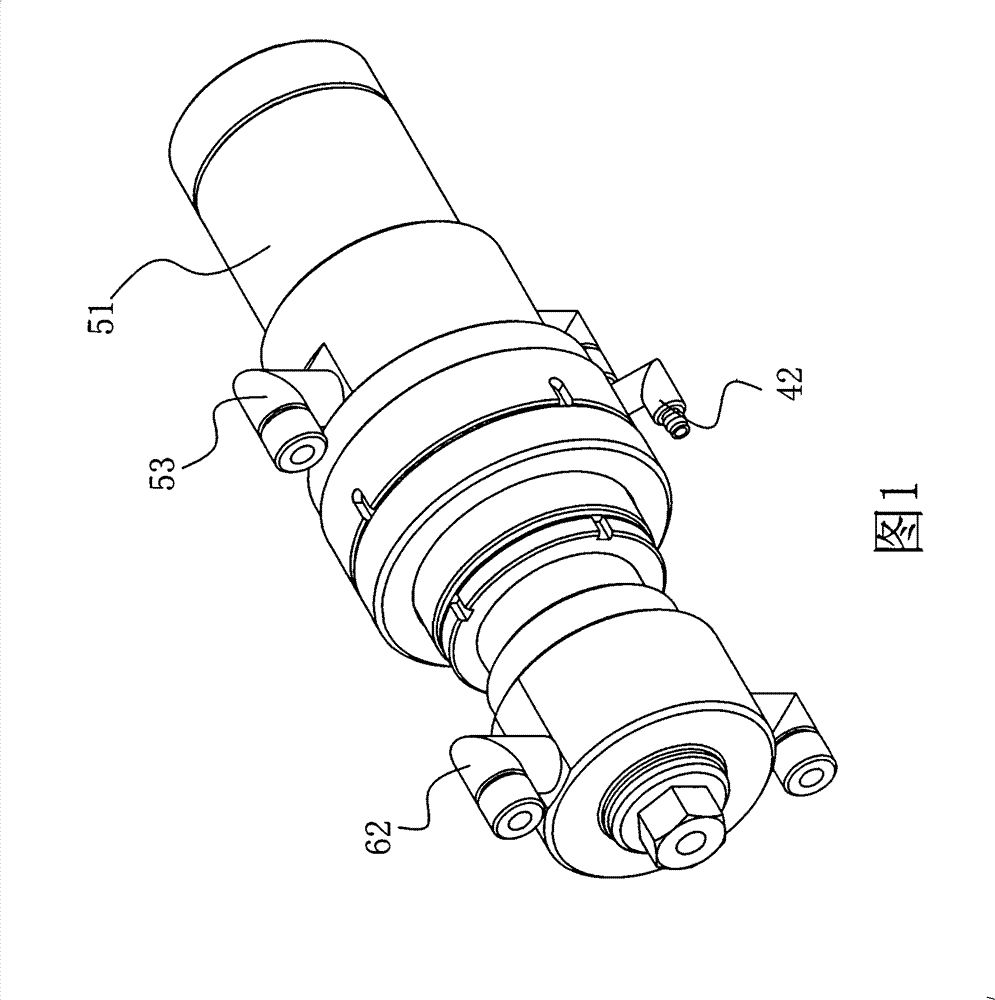

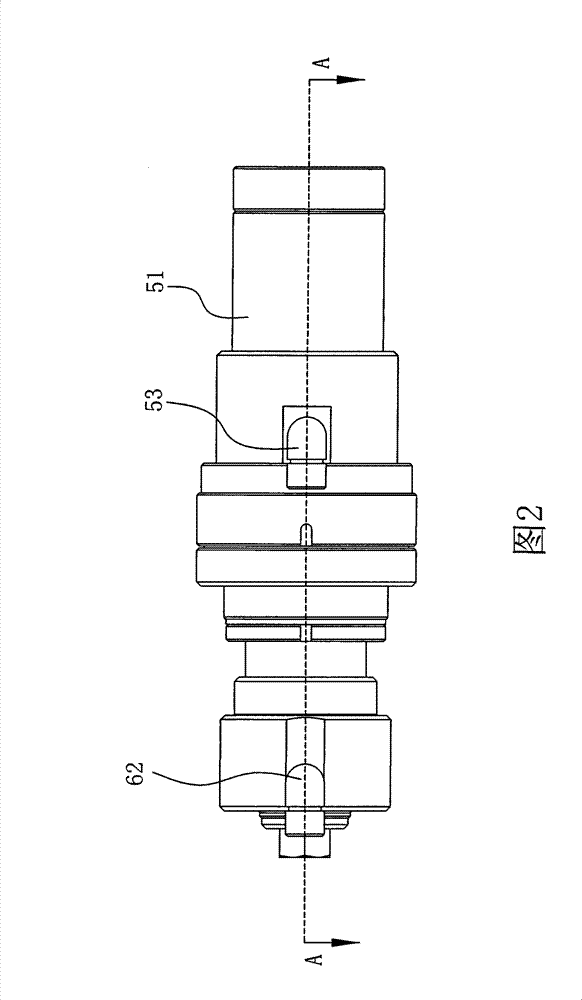

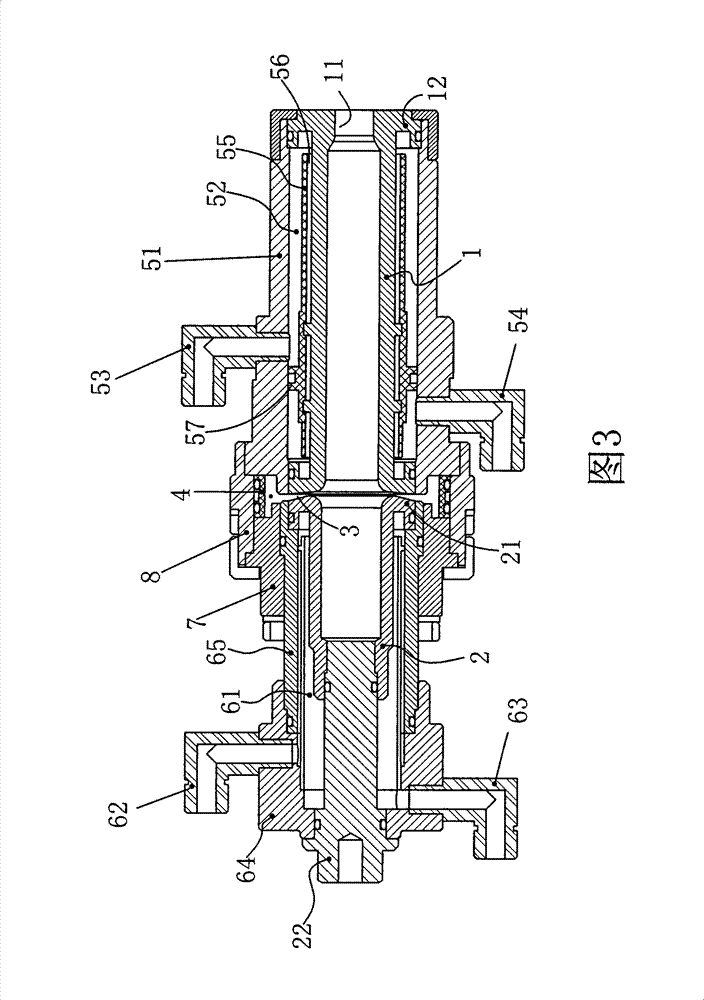

[0032] like Figure 1-4 As shown, the present invention proposes an AC plasma launch gun, which can directly utilize a single-phase power supply in 380V AC to generate plasma. The firing gun includes a front electrode 1 and a rear electrode 2 . The front electrode 1 can be a hollow cylindrical electrode, and is connected to the zero line of the power supply. The outlet end of the front electrode 1 (ie, the end far away from the rear electrode 2 ) is provided with a nozzle 11 . The rear electrode 2 can be a hollow cylindrical electrode, and is connected to the live wire of the power supply, and the end of the rear electrode 2 away from the front electrode 1 is closed. There is a gap 3 between the end surfaces of the front and rear electrodes, the gap is preferably 1-4mm, and a swirl air intake ring 4 is provided, the air inlet of the swirl air intake ring 4 is located outside the gap 3, Make the compressed air pass through the swirl inlet ring 4 to form a supersonic swirling ...

Embodiment approach 2

[0041] On the basis of the above-mentioned embodiment, the closed end of the rear electrode 2 is connected with a terminal 22, and the axial direction of the terminal 22 is provided with a through hole (not shown) for connecting compressed air, and the compressed air flows from the The through hole enters the inner wall of the rear electrode 2, and while cooling the rear electrode 2, it can also move the arc forward.

[0042] Other structures, working principles, and beneficial effects of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com