Presetting positioning fusion process for inner central layer of printed circuit board

A technology for printed circuit boards and inner-layer core boards, which is applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of large board warpage, low alignment accuracy, and large inter-layer alignment offset, so as to reduce the The effect of positioning error and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The processing route of the inner layer of the multi-layer board is as follows:

[0015] Substrate cutting→pretreatment→inner layer D / F or photosensitive oil→developing / etching / removing film→AOI→black / brown oxidation→pre-arrangement (fusion, rivet)→board arrangement→pressing plate→drilling positioning holes→pressing plate forming→ Outer process.

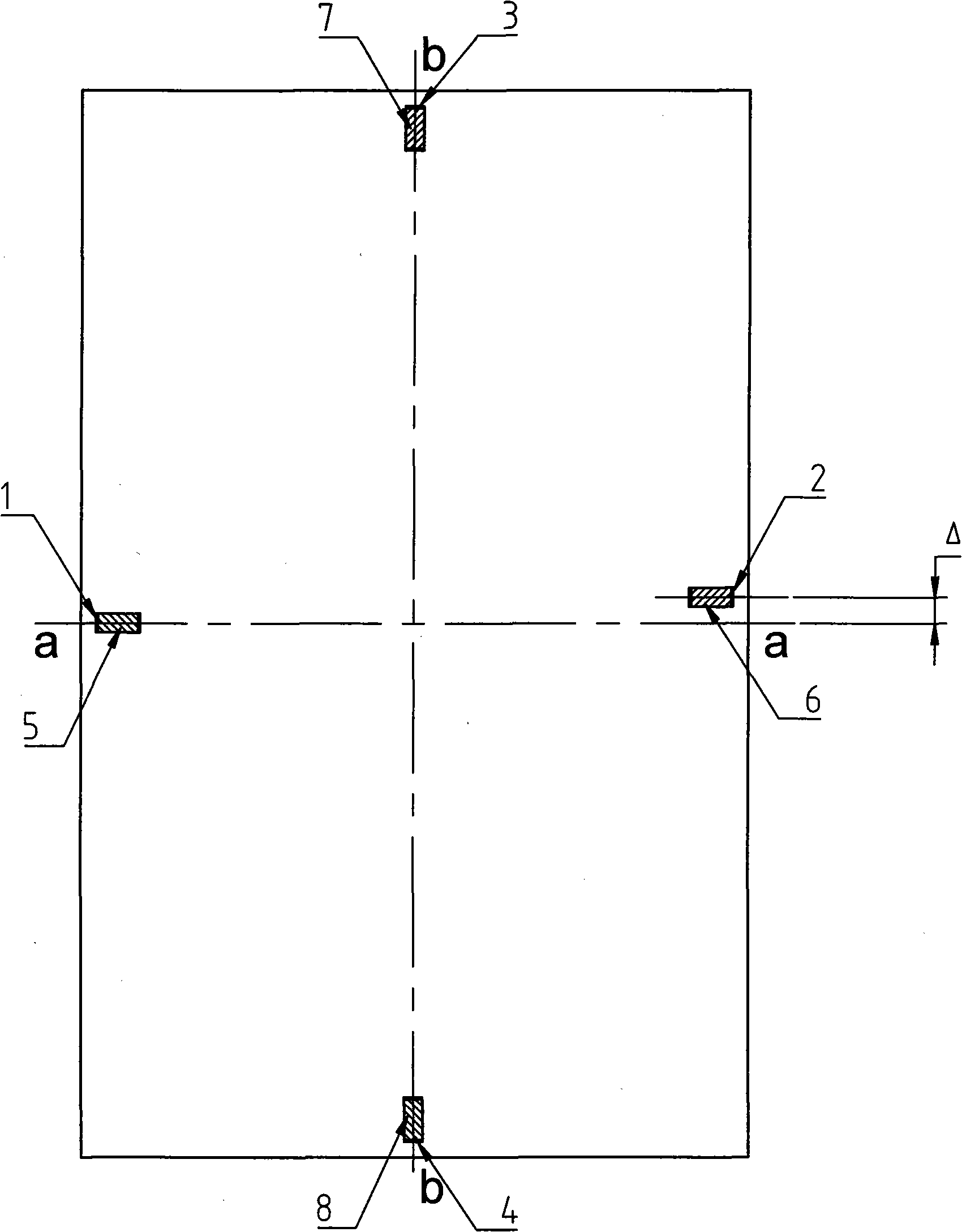

[0016] The invention mainly relates to the punching of inner core boards, and the prearrangement and fusion of the inner core boards. It is characterized in that, in the step of punching the inner core plate, four positioning holes are punched on the core plate, and the four positioning holes are scattered close to the edges of the four peripheral edges of the core plate, and the fusion machine workbench is provided with four corresponding Locating pins, pre-arranged and then heat-pressed and fused.

[0017] In the embodiment of the pre-arrangement positioning fusion process of the inner layer core board of the printed circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com