Machine for the production of bags made of heat-sealed alveolar or foamed thermoplastic material

A thermoplastic material and machine technology, used in envelope/bag manufacturing machinery, bag making operations, container manufacturing machinery, etc., can solve problems such as high cost, complexity, and low production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

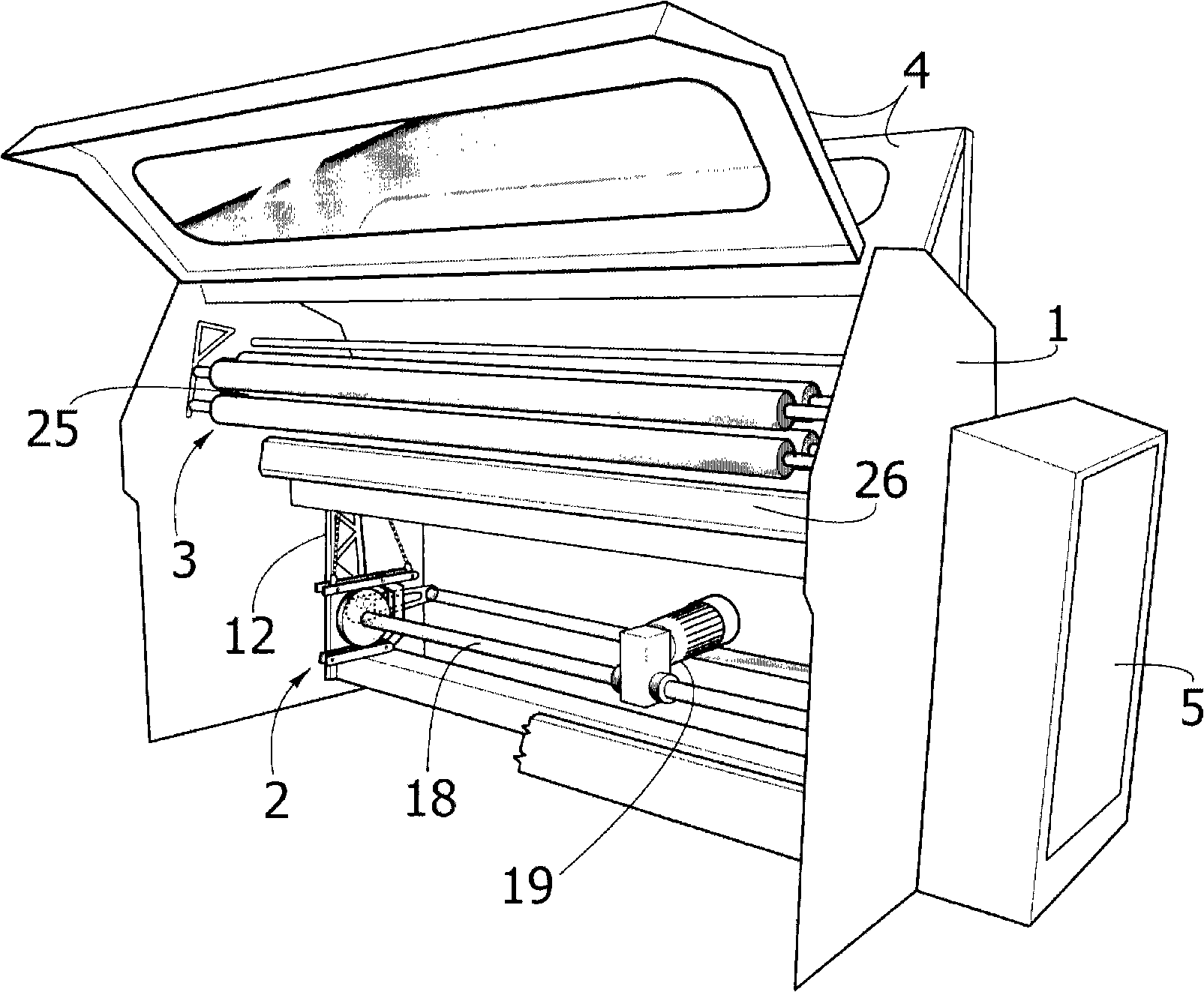

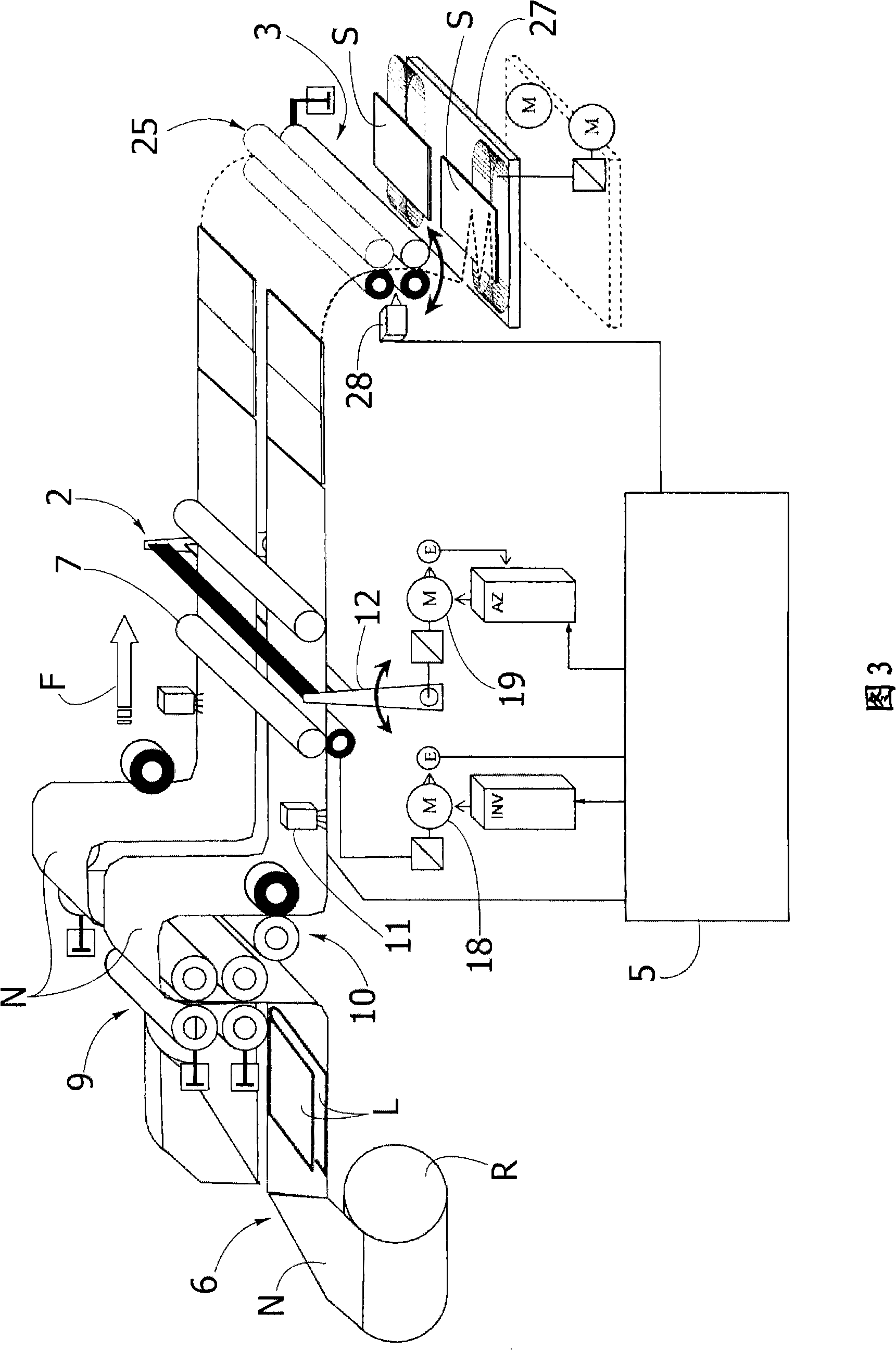

[0019] first refer to figure 1 and FIG. 3 , the machine of the invention basically comprises a support structure 1 and a pull-and-fold assembly denoted 3 as a whole. The support structure 1 has less horizontal hindrance and supports the heat-sealed assembly indicated at 2 as a whole; At the sides of the support structure 1 there is provided a cabinet in which is housed a programmable electronic control unit 5 for controlling the operation of the above-mentioned machine.

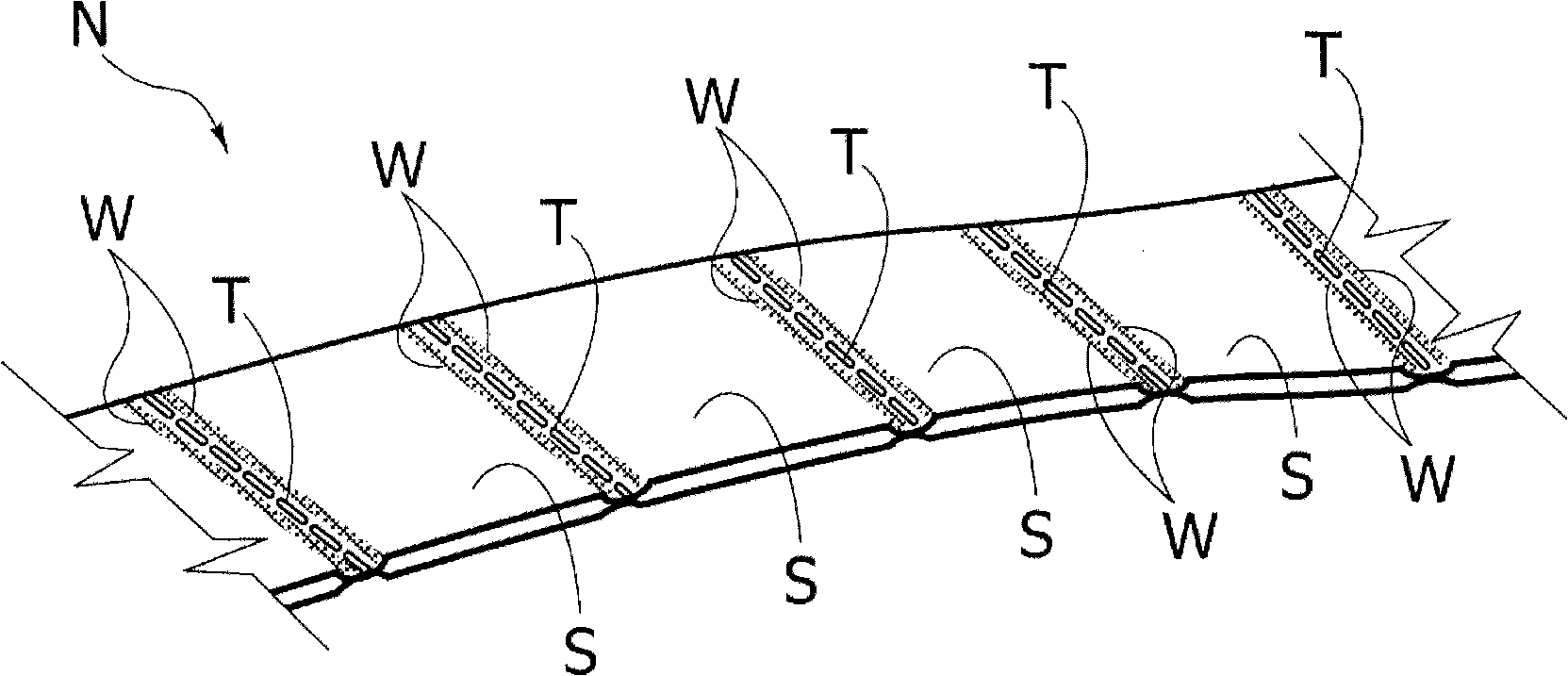

[0020] As shown schematically in Figure 3, uncoiling device 6 is connected to the rear side of the machine for unwinding at least one continuous strip N uncoiled from reel R, which strip N is a thermoplastic material, usually in the form of a bubble (i.e., Polyethylene with bubbles) or foamed polyethylene. Depending on the width of the machine, an uncoiling device 6 can be prearranged for unwinding strips N of different widths as well as two or more strips N. The example described concerns precisely the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com