Method for gas stripping and separating hydrazine from hydrazine-containing solution using acetone and use thereof

An acetone and solution technology, which is applied in the fields of hydrazine, hydrazine preparation, nitrogen and non-metallic compounds, etc., can solve the problem of high energy consumption and achieve the effect of solving condensation wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

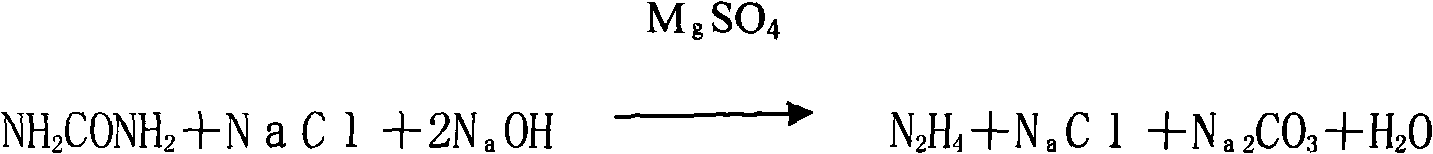

Method used

Image

Examples

Embodiment Construction

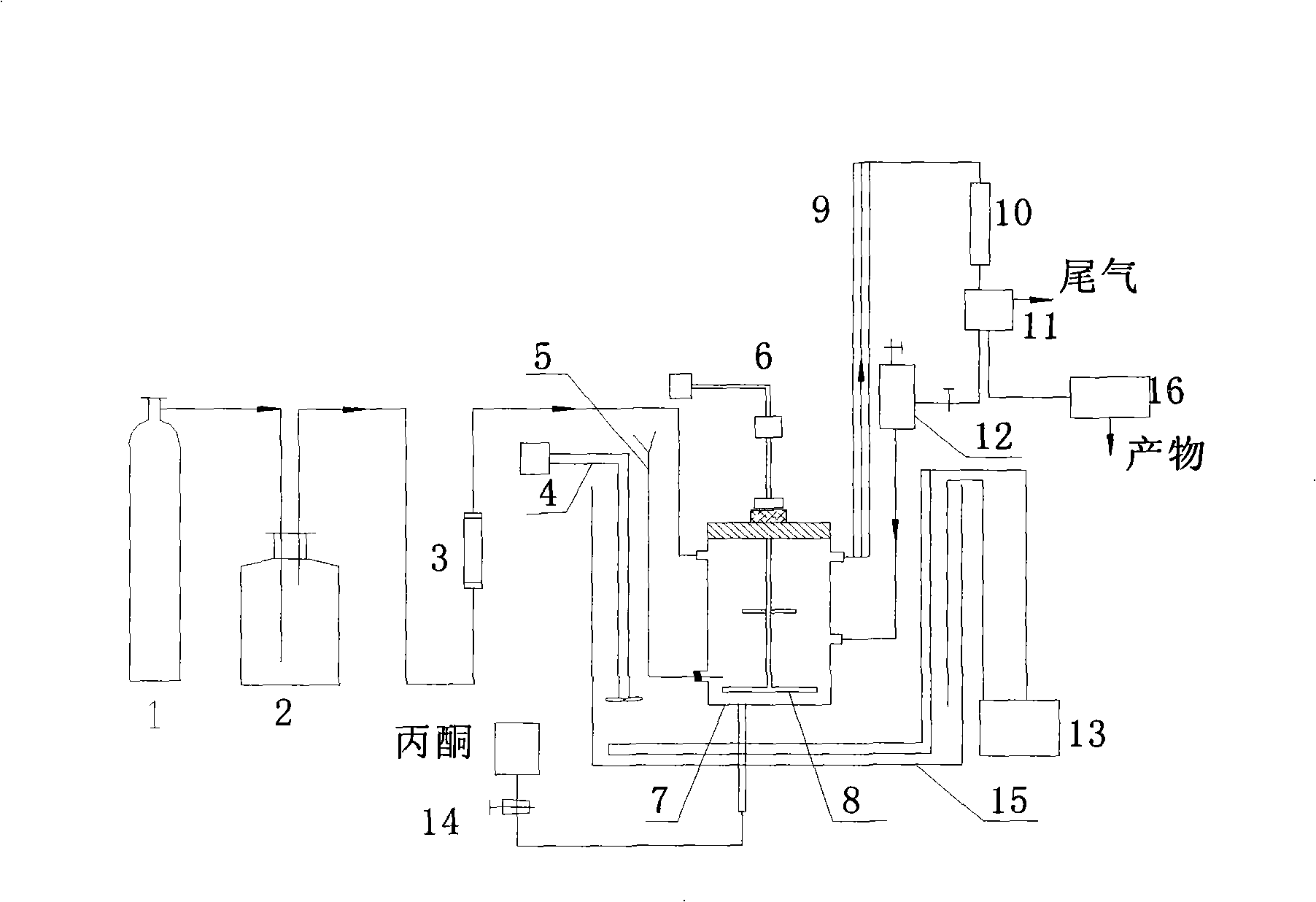

[0018] The experiment was carried out under normal pressure, and the operation method was basically the same as that of the batch rectification device. First, add the crude hydrazine hydrate liquid from the feed port to the self-priming stirred bubbling reactor, turn on the power to make the stirrer start to rotate at a certain speed, and start to add acetone dropwise when the temperature of the oil bath rises to the set value. The acetone is directly vaporized and the hydrazine in the solution is stripped, and the acetonazine is evaporated and then enters the condenser after heat preservation, and the condensed liquid is directly collected, and then the hydrolysis device is used for hydrolysis reaction.

[0019] Low concentration hydrazine solution reaction embodiment 1:

[0020] Hydrazine hydrate crude liquid 200ml (hydrazine hydrate content is 51.2g / l, the same below), acetone 60ml (the feed molar ratio of acetone and hydrazine is 3.6) reaction temperature 100 ℃.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com