Driving speed-changing mechanism of electric vehicle

A speed change mechanism and electric vehicle technology, applied in the direction of mechanical equipment, transmission devices, gear transmission devices, etc., can solve the problems of electric vehicle battery life decline, energy storage element-battery damage, etc., to achieve safe use, strong battery life, overcome The effect of the shock problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

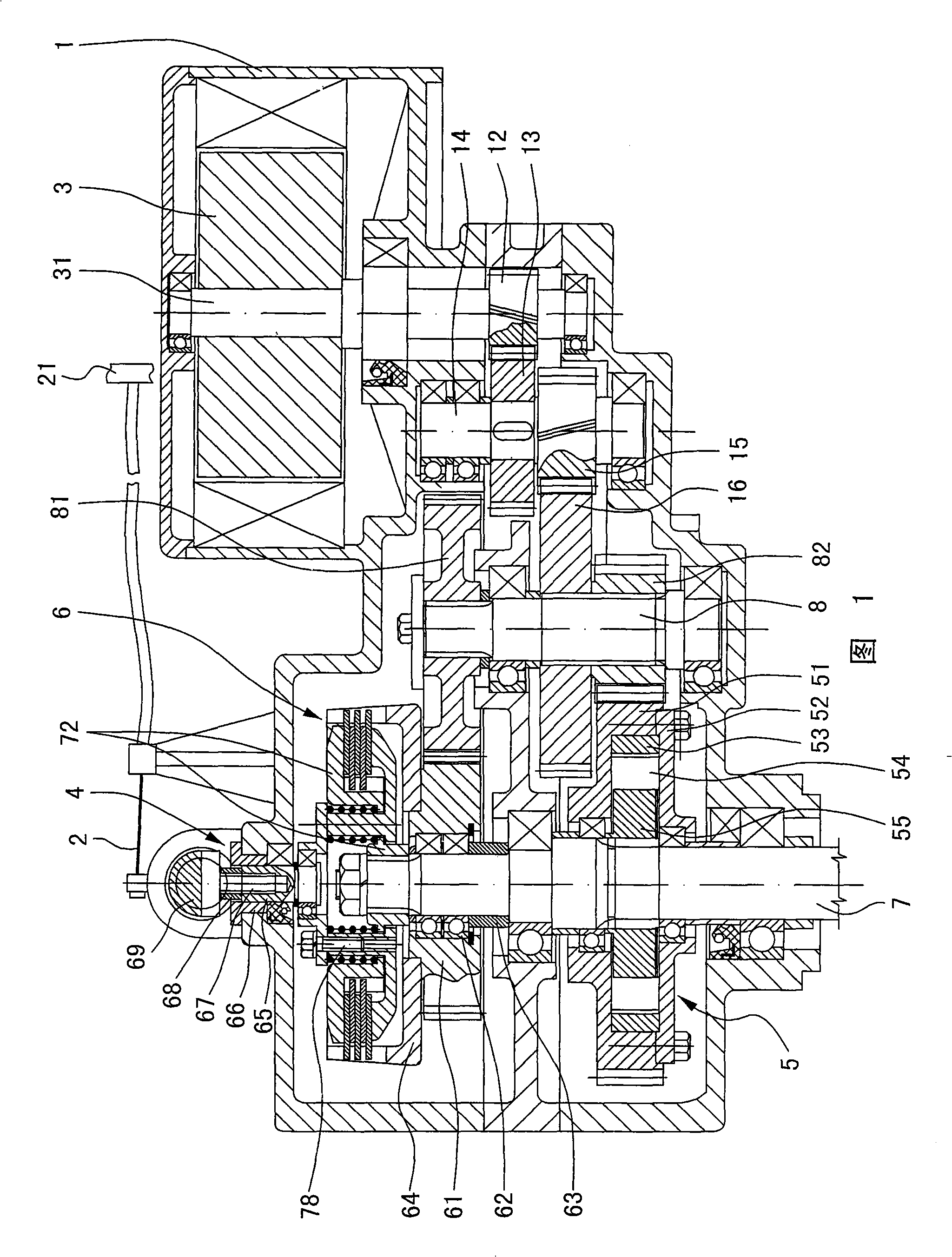

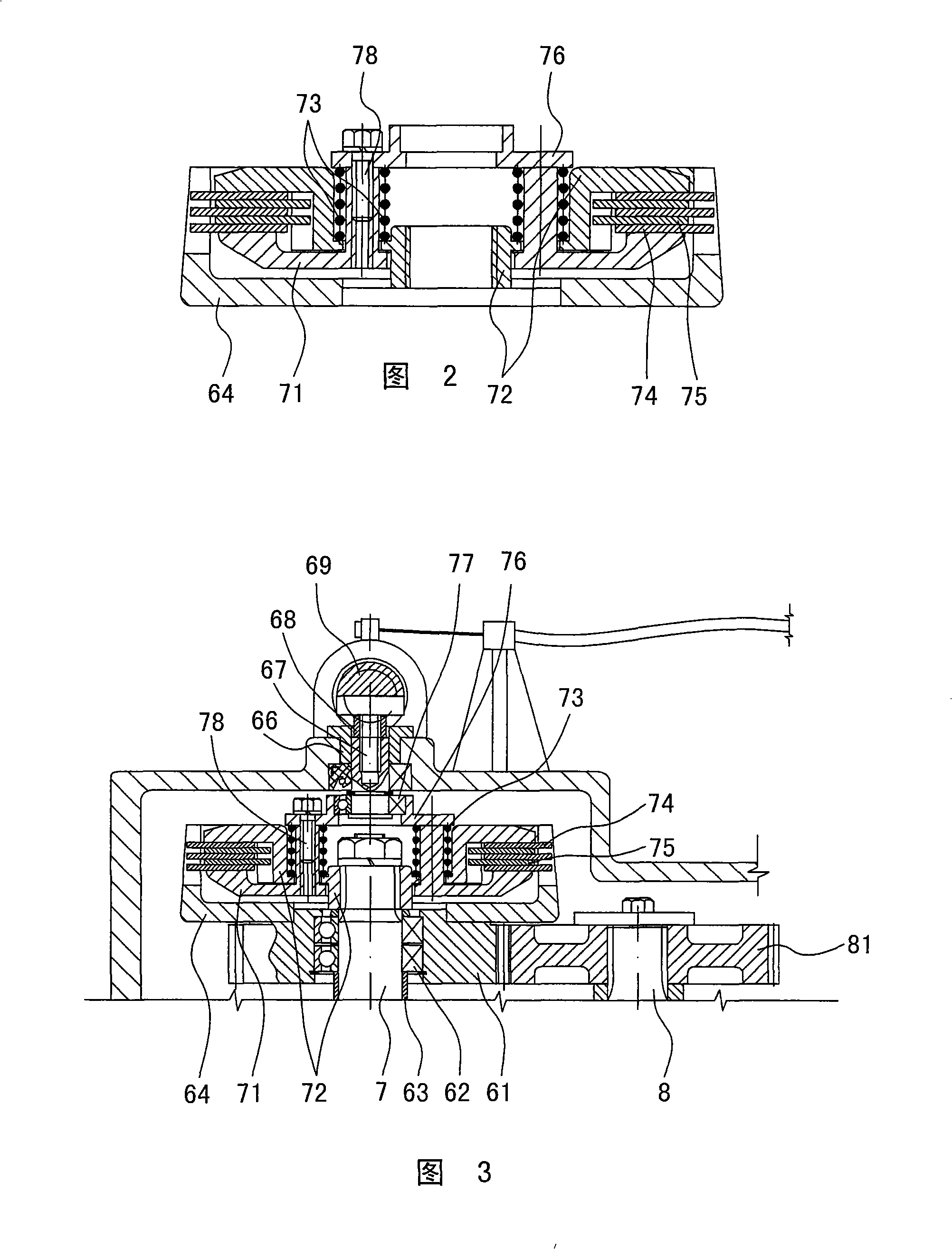

[0010] The present invention relates to an electric vehicle drive speed change mechanism, as shown in Figures 1-3, there is a gearbox body 1, and a motor 3 is installed in the box body, the motor gear shaft 31 drives the output shaft through the transmission mechanism, and the output shaft drives the electric wheel hub , its main technical feature is that the transmission mechanism is: the motor gear shaft 31 drives the reduction gear set, the reduction gear set drives the switching shaft 8, one end of the switching shaft 8 is equipped with a friction switching gear 81, and the other end of the switching shaft is installed with an overrunning switch Gear 82, the overrunning switching gear 82 drives the overrunning clutch 5, and the overrunning clutch 5 cooperates with the output shaft 7; the friction switching gear 81 drives the multi-plate friction clutch 6, and the multi-plate friction clutch 6 cooperates with the output shaft 7. One end of formula friction clutch 6 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com