Pipeline detection robot driven based on electrokinetic material and pipeline detection system thereof

An electrical actuation material, pipeline detection technology, applied in the direction of pipes/pipe joints/pipes, special pipes, pipe components, etc., can solve the problems of inconvenient portability, complicated operation, high power consumption, etc., to optimize the movement form, battery life Powerful, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

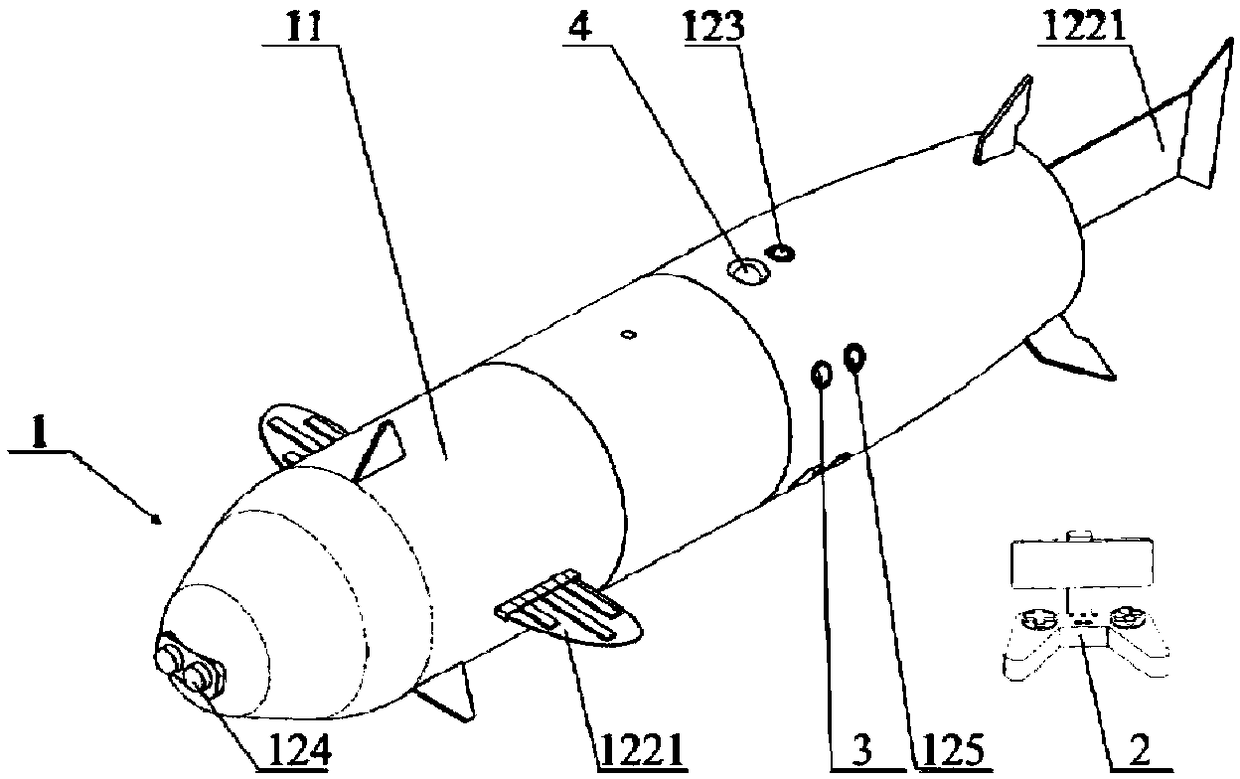

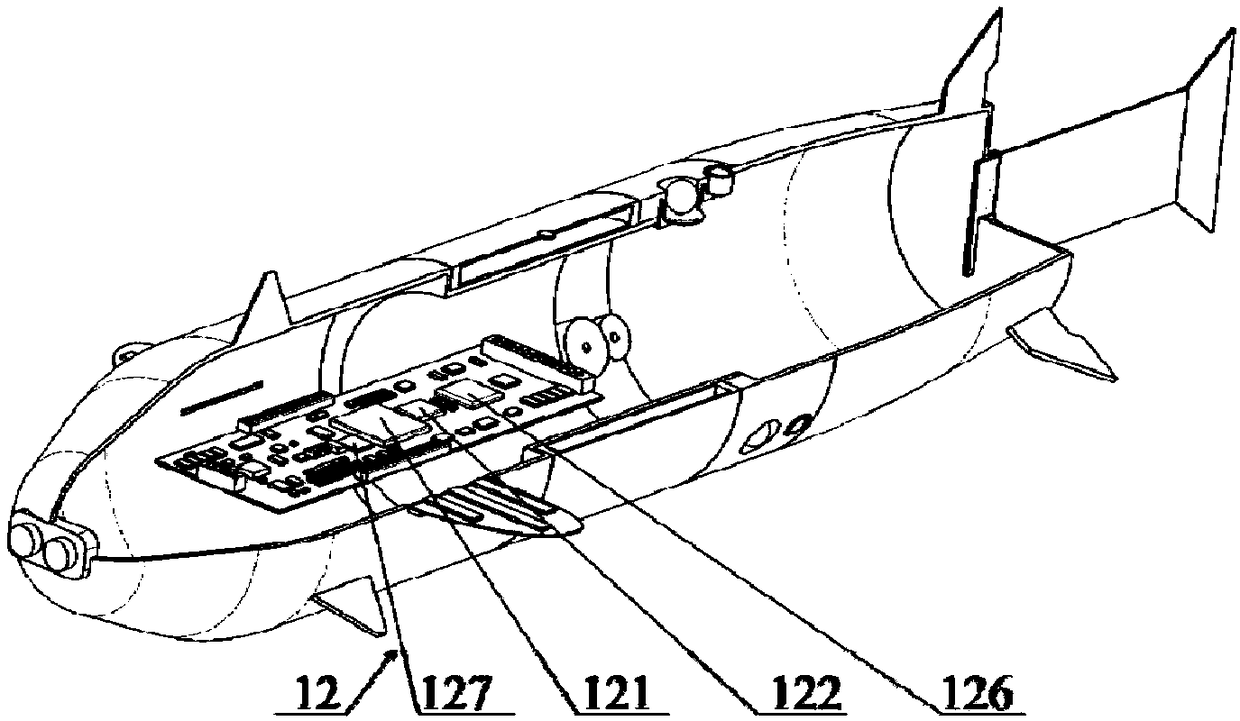

[0058] Such as Figure 1-3 As shown, this embodiment discloses a pipeline detection robot driven by electric actuation materials, including a main body 1 and a terminal 2 . Terminal 2 interacts with Body 1. The main body 1 includes a housing 11 and a pipeline detection system 12 , and the pipeline detection system 12 is integrated on the housing 11 . The pipeline detection system 12 includes a control module 121 , a drive module 122 , a channel self-correction module 123 , an obstacle avoidance module 124 , a detection module 125 , a positioning module 126 , and a signal transmission module 127 .

[0059] The driving module 122 includes a driving body 1221 and a single-chip microcomputer (not shown in the figure). The driving body 1221 is made of an electrically actuated polymer material, and the single-chip microcomputer is electrically connected to the driving body 1221 .

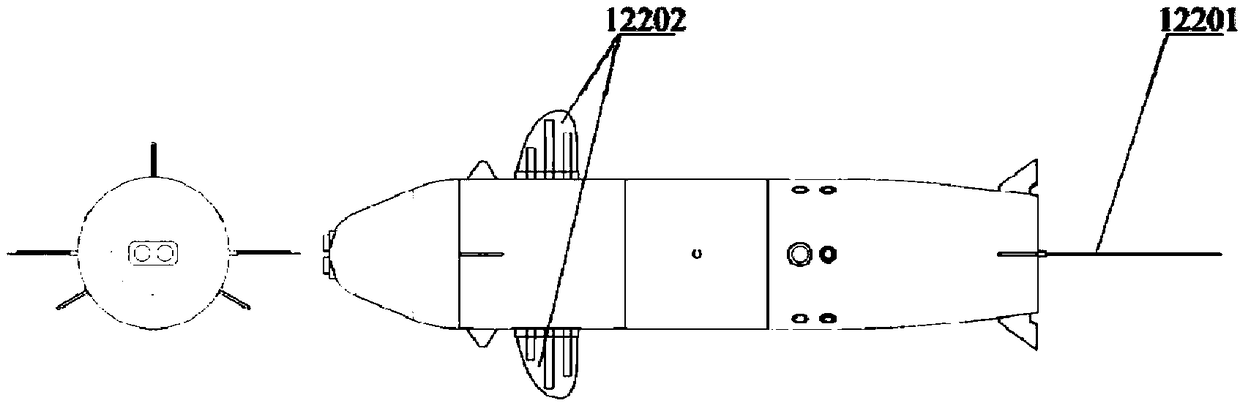

[0060] The driving module 122 of the present invention includes a tail driving body 12201 and a pect...

Embodiment 2

[0076] The difference between this embodiment and the foregoing embodiments is that the material of the housing 11 is polyethylene, polypropylene, polyvinyl chloride, phenolic resin, aminoplast, acrylonitrile-butadiene-styrene copolymer, polycarbonate, nylon , one or more kinds of photosensitive resins; or other lightweight solid waterproof materials of the prior art.

Embodiment 3

[0078] Such as Figure 5 As shown, the difference between this embodiment and the above-mentioned embodiments is that the housing 11 includes a front guide body 111, a front part of the housing 112, a weight cabin 113 in the middle of the housing, a tail part 114 of the housing, a tail guide body 115, and a front part of the housing 115. Part 112, the weight compartment 113 in the middle of the housing, and the tail part 114 of the housing are detachably connected in sequence.

[0079] The outline size of the housing 11 of the present invention is preferably: 400mm×94mm (length×diameter). Specifically, the housing 11 can be obtained by 3D printing. The printing material is photosensitive resin, and its density is about 1.3g / cm 3 ; Or the housing 11 of the present invention can also adopt other existing technologies such as injection molding.

[0080] The front-end deflector 111 is located on the front portion 112 of the housing. The front-end guide body 111 has a triangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com