Composite type full-liquid type heat converter for refrigerant circulation system

A heat exchanger and circulation system technology, applied in the field of heat exchangers, can solve the problems of improper use of an evaporator as a condenser, reducing the circulation efficiency of the condensation effect, increasing the manufacturing cost and difficulty, and improving the heat exchange efficiency, The effect of reducing investment cost and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

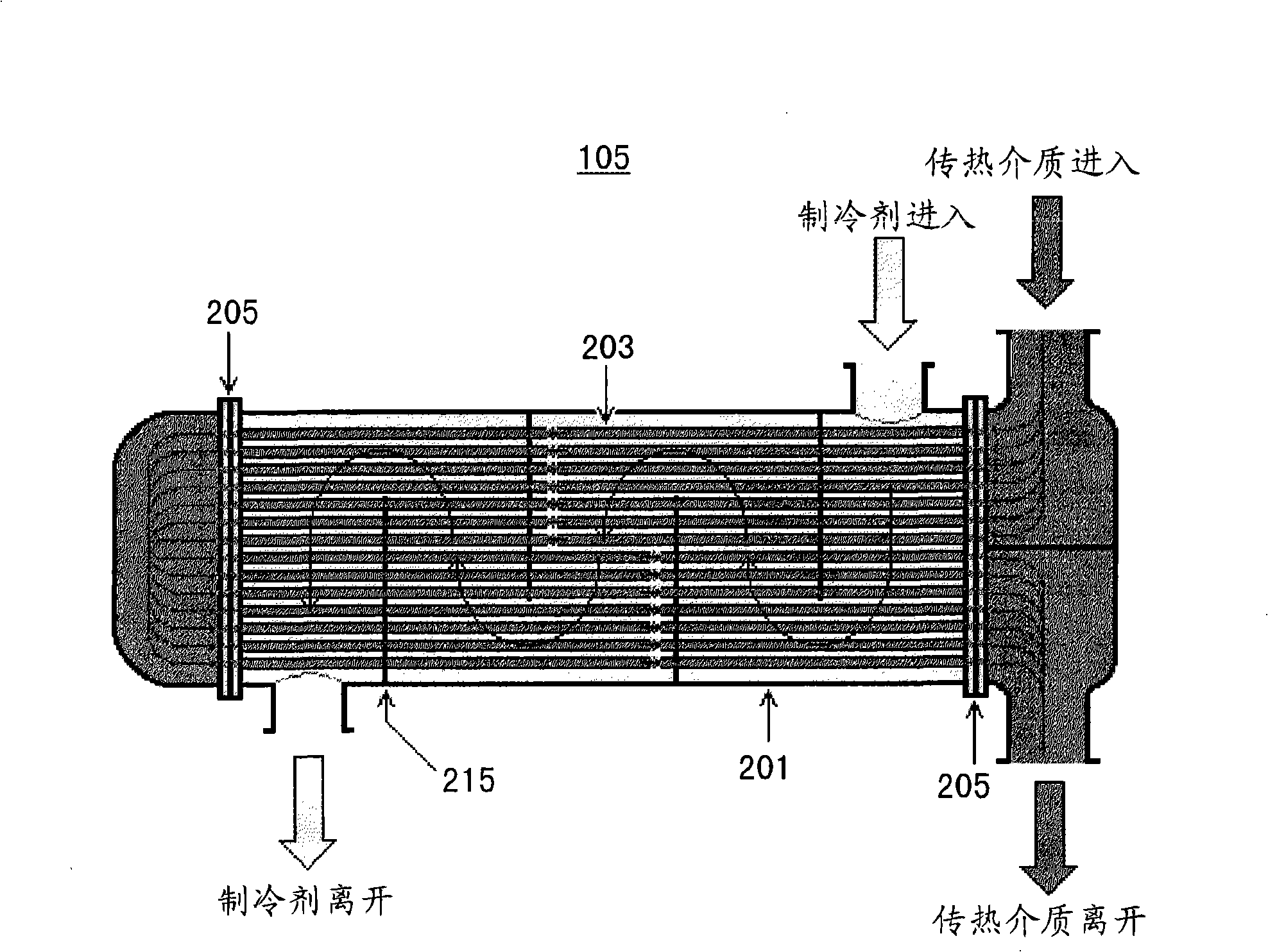

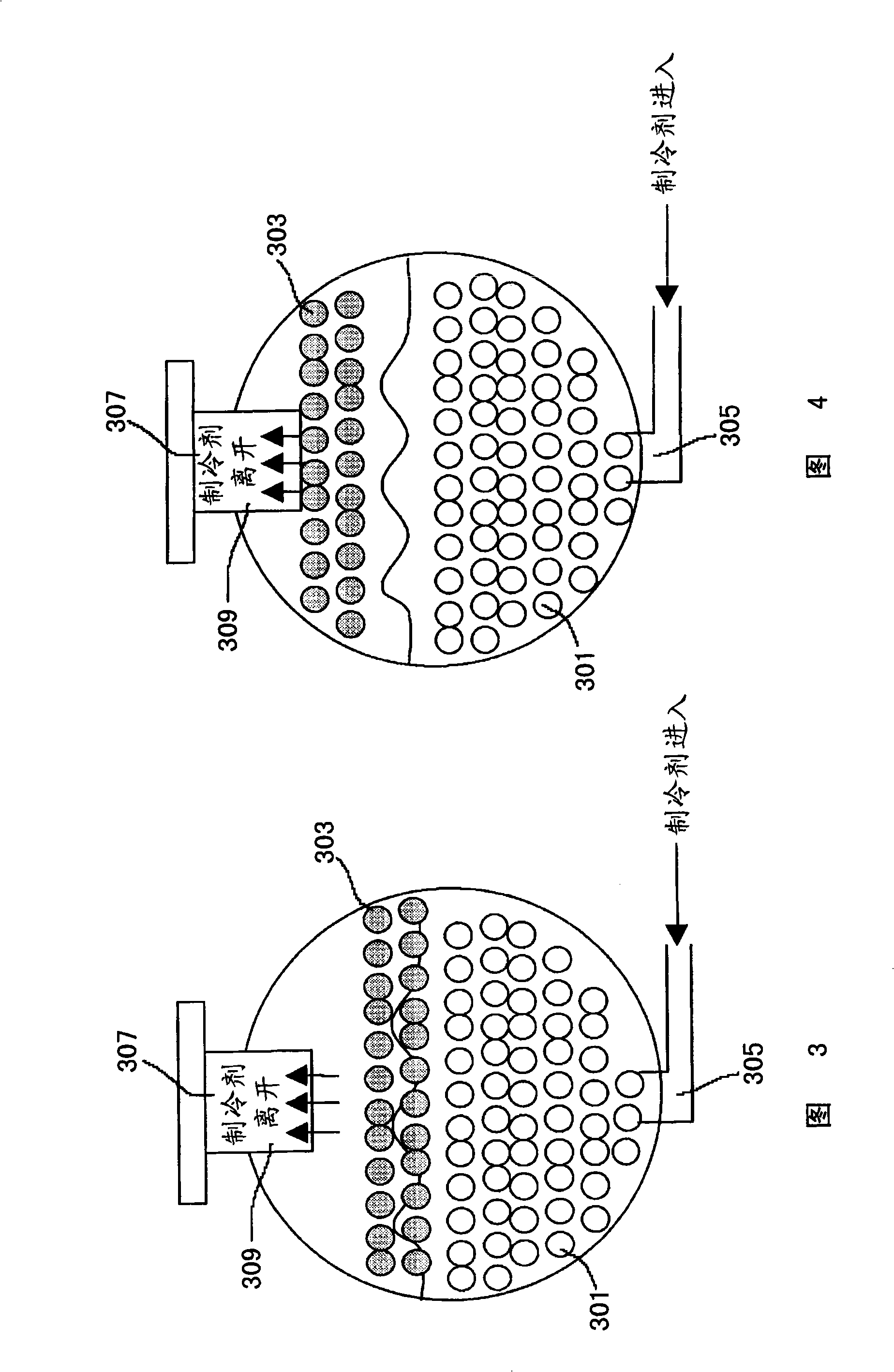

[0020] Hereinafter, the heat exchanger of the present invention will be described in detail with reference to the accompanying drawings. Although in the preferred embodiment of the present invention, it is described with reference to a horizontal shell-and-tube heat exchanger, those of ordinary skill in the art should understand that the heat exchanger of the present invention is not limited thereto, and the heat exchange principle of the present invention can be Any other suitable heat exchangers are applicable, such as vertical shell-and-tube heat exchangers, water-cooled shell-coil heat exchangers, and the like. In addition, although the present invention is described with reference to a vapor compression heat pump refrigerant cycle, those of ordinary skill in the art should understand that the heat exchanger of the present invention can also be used in other types of refrigerant cycles.

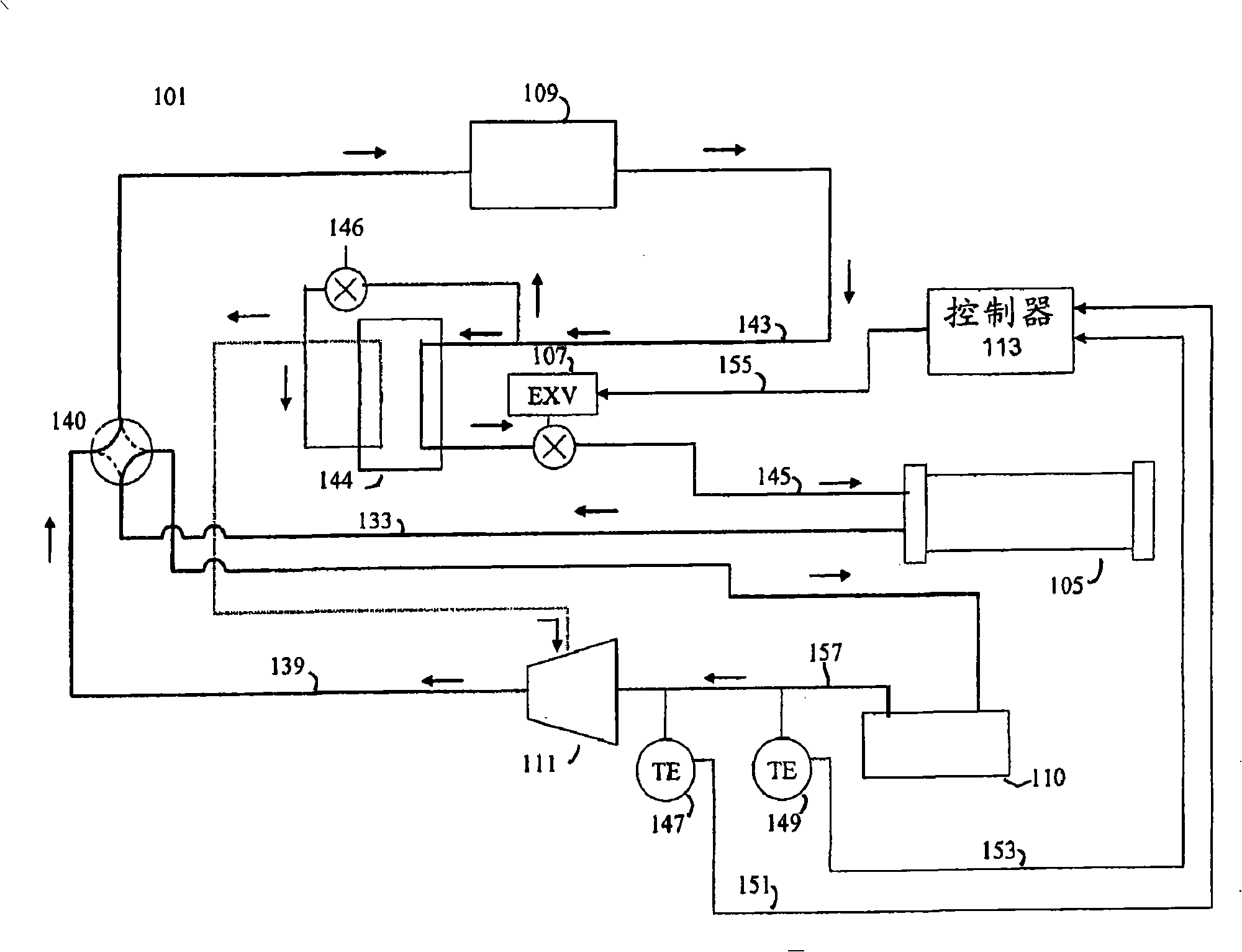

[0021] figure 1 A refrigerant cycle of an exemplary heat pump air conditioning syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com