Drilling tool

A technology for drilling tools and tools, which is applied to drilling accessories, manufacturing tools, drilling/drilling equipment, etc. It can solve problems such as processing troubles, failure to obtain broken life, troublesome inspections, etc., and achieve simple shapes and difficult Effects of breakage, ease of manufacture and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

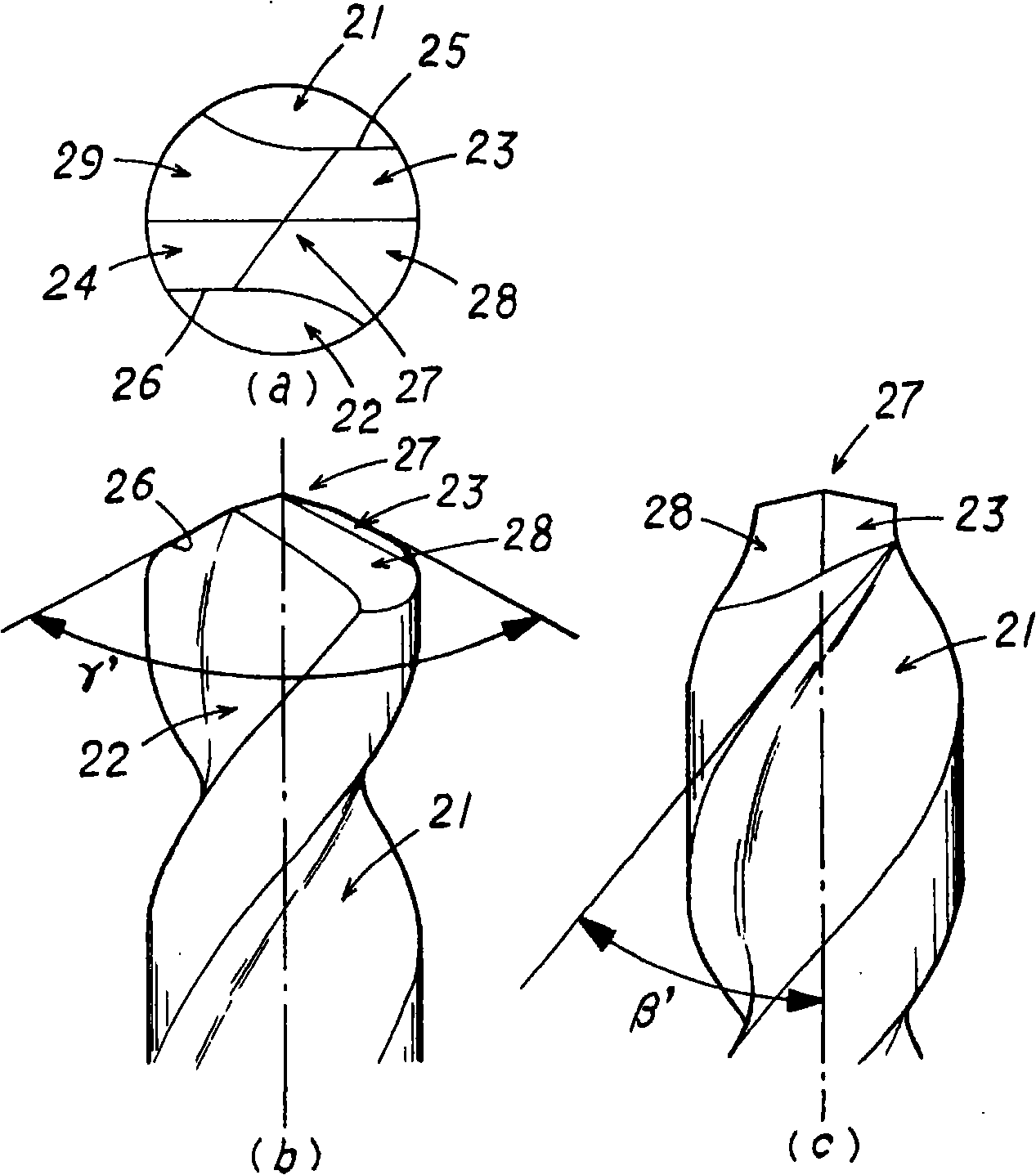

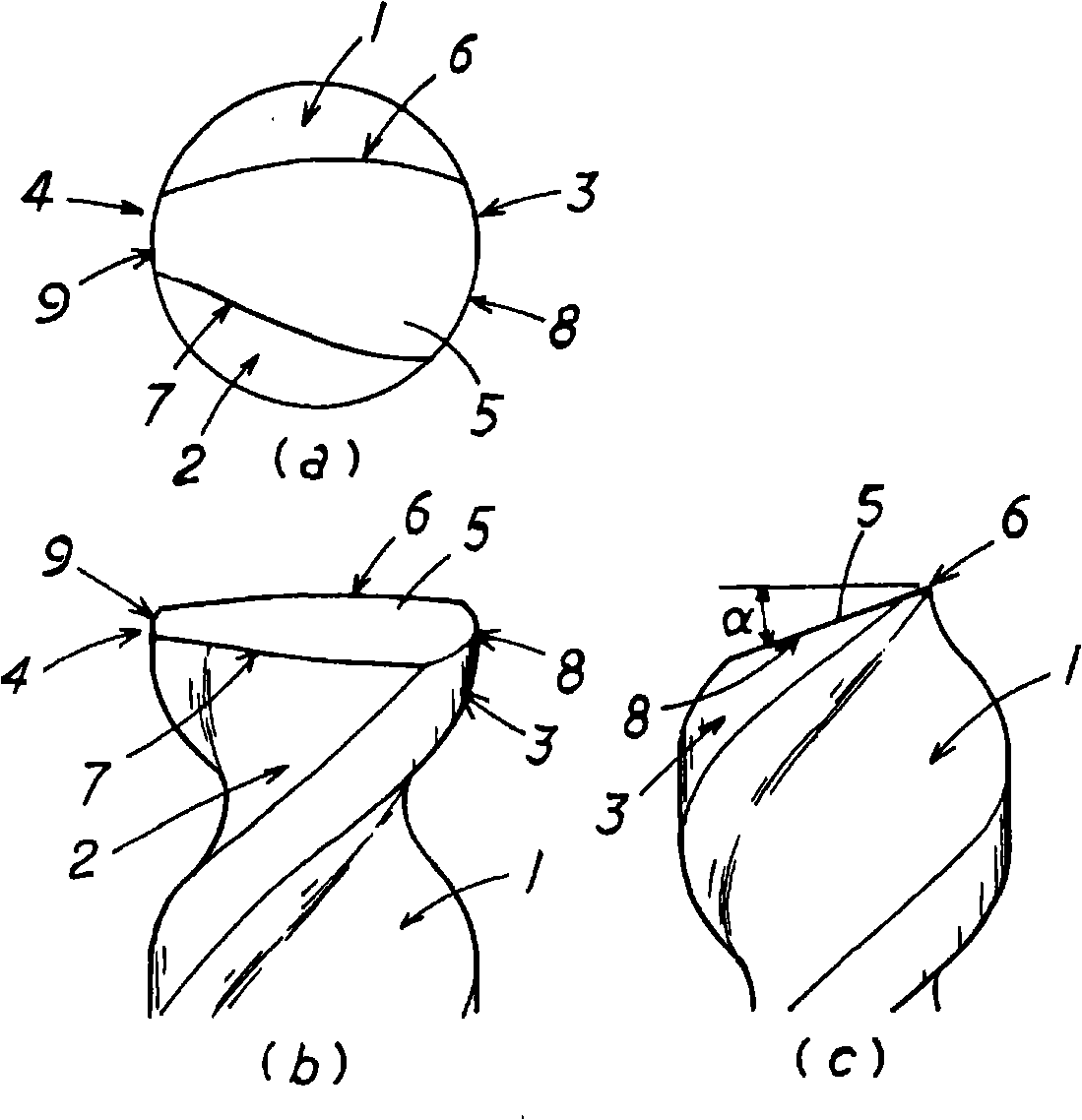

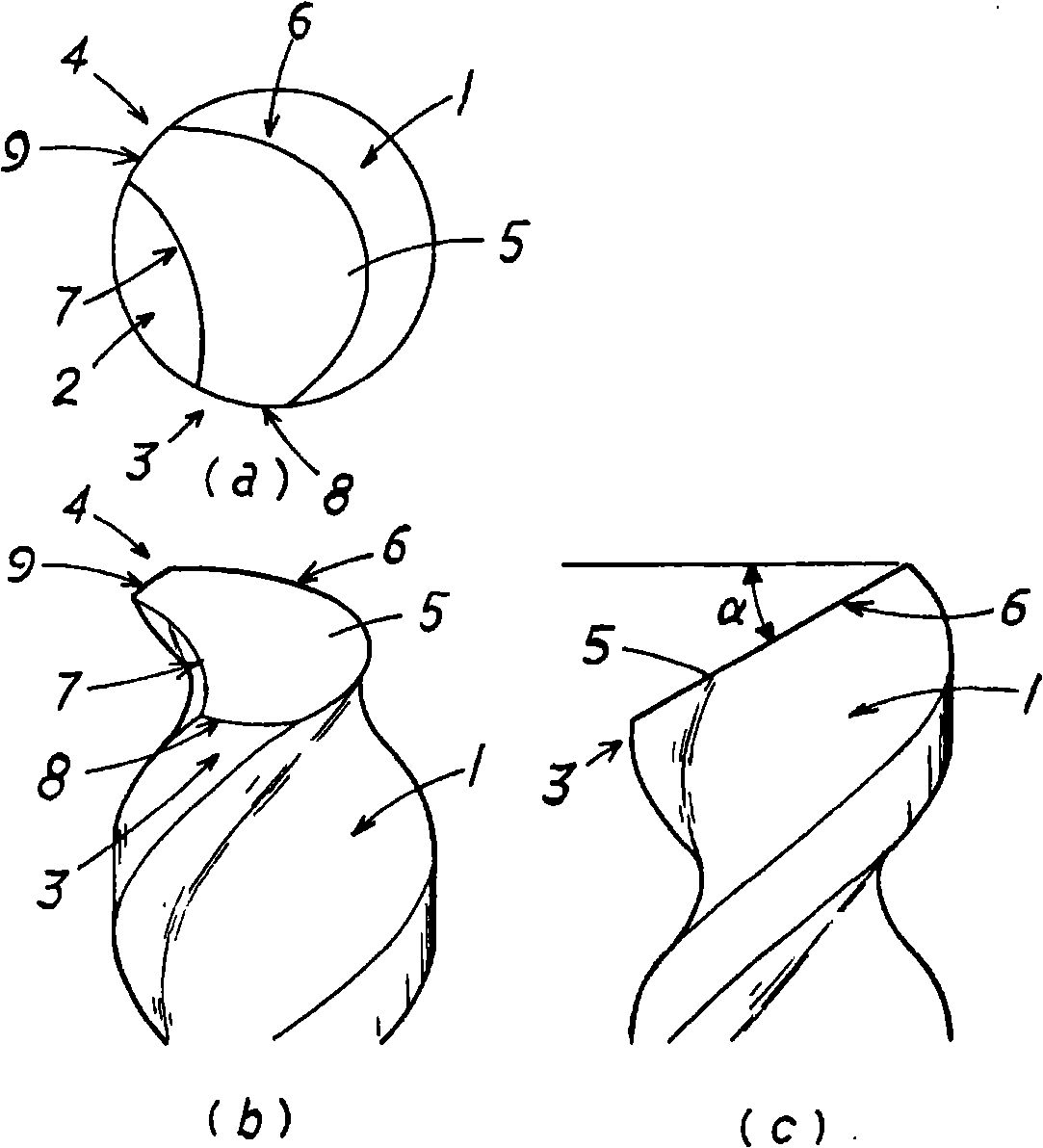

[0035] The action of the present invention is shown based on the drawings, and preferred embodiments of the present invention are briefly described.

[0036] The drilling tool of the present invention is provided with a flat drill point surface 5 without ridges at the tool tip, and has a chisel edge near the center of the tool tip, for example, and is connected to the chisel edge to form a predetermined drill point angle. The cutting edge of the ordinary drill bit is different, and the thrust direction (the axial direction of the tool) is used to bear most of the cutting resistance during the hole machining process, so as to reduce the external force in the direction at right angles to the tool axis (the cutting force during the hole machining process). The bending stress generated by the resistance) is not easy to break.

[0037] Furthermore, cutting is gradually performed while the most protruding part of the drill point surface 5 (the crossing ridge with the land portion or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com