Star shaped casing tube preheater for large-scale canalization dissolving out apparatus

A pipeline and preheater technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed tubular conduit components, etc., can solve the problems of low work efficiency, improve efficiency, improve uniformity, increase heat Effect of Exchange Surface Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

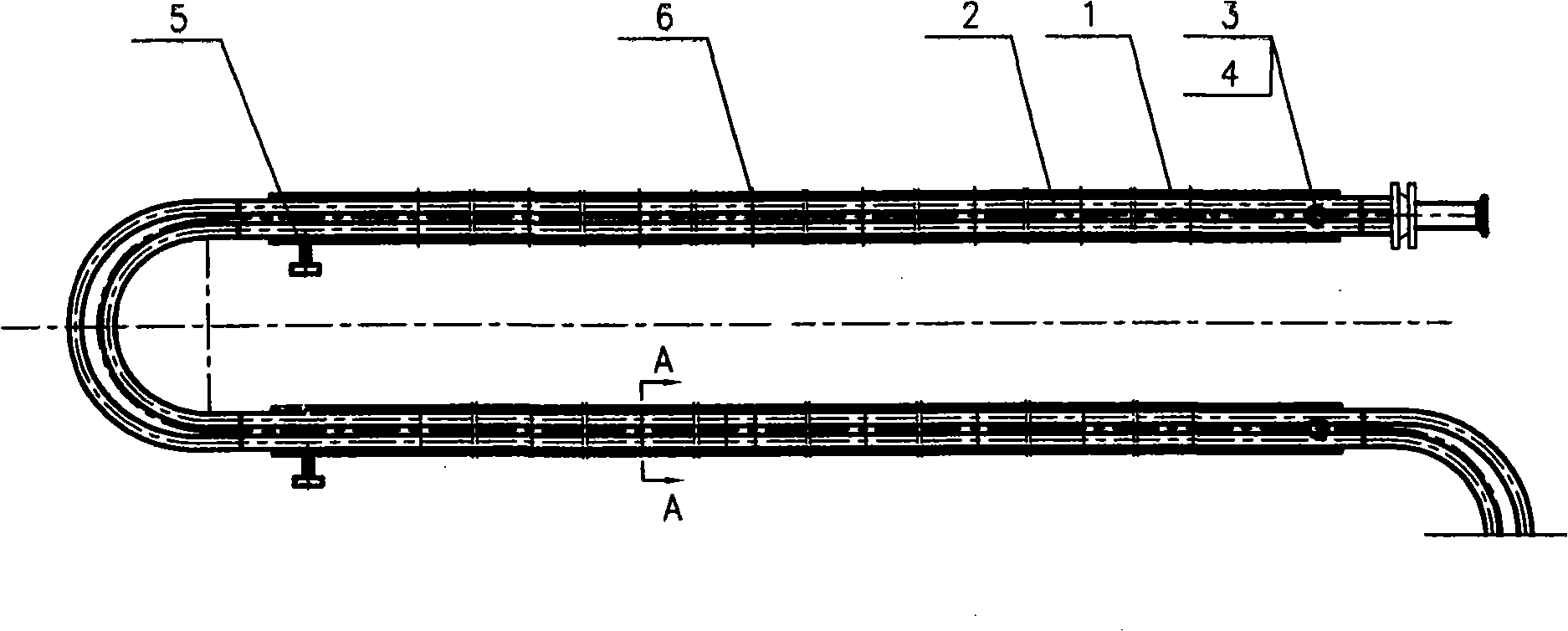

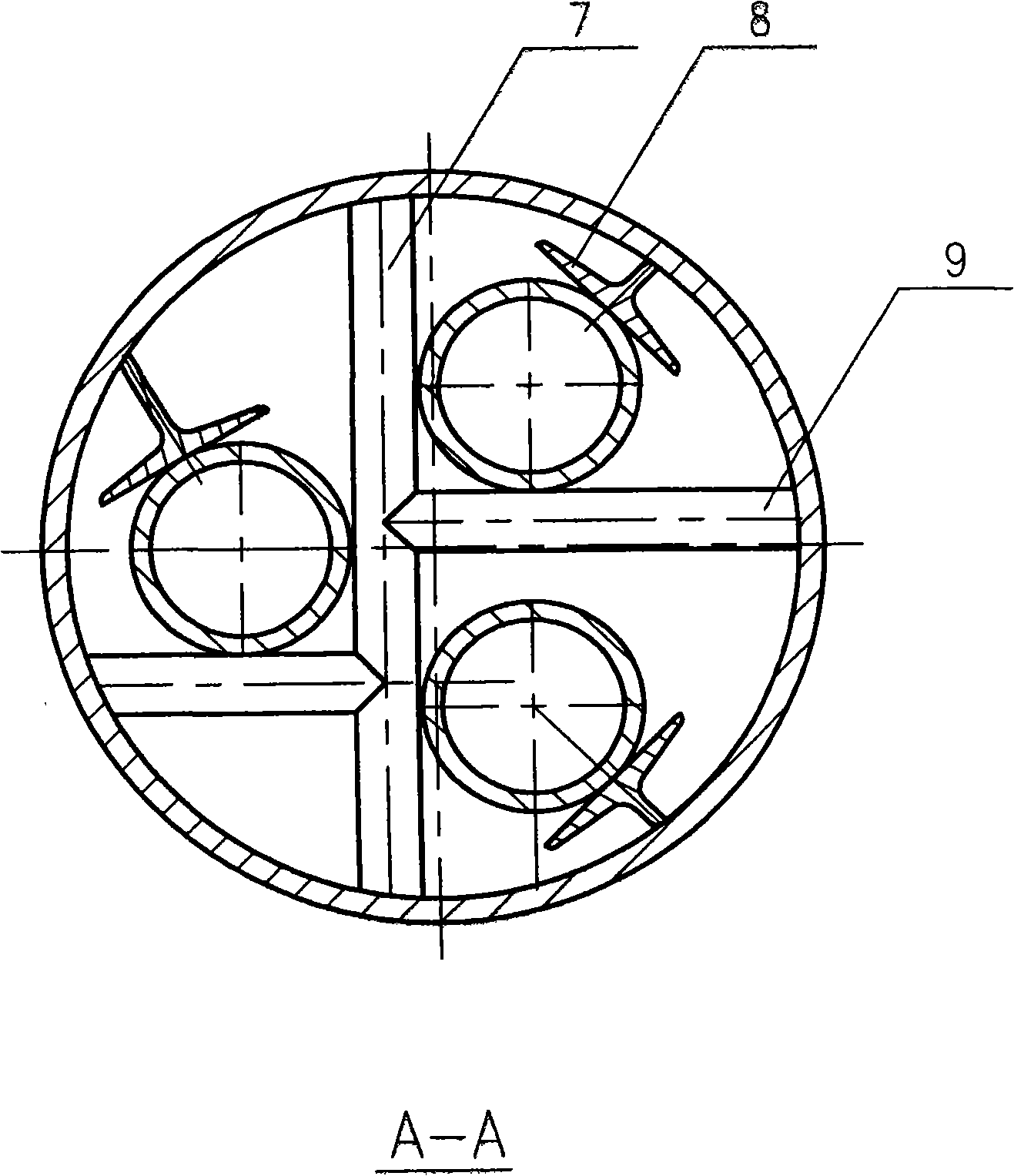

[0017] Embodiment 1 Top frame fixed star casing preheater

[0018] like figure 1 and 2 shown. Take a steel pipe of φ530mm as the outer casing 1 and press the two ends of the steel pipe figure 2 In the shown scheme, a bracket vertical tube 7 is welded on first, and then a bracket horizontal tube 9 is welded on both sides of the vertical tube to divide the inner space of the outer tube into three large and small parts, and then in the three large spaces T-shaped top frame 8 is welded on the inner wall of the outer tube at the position opposite to the joint of the support vertical tube and the horizontal tube. The space between the top frame and the vertical and horizontal pipes can accommodate the inner pipe 2 to pass through without allowing it to roll or slip. The inner pipe is a steel pipe of φ159×12mm. In the assembled type, three inner tubes are first inserted into the bracket at one end of the outer tube and passed out from the bracket at the other end, and then the ...

Embodiment 2

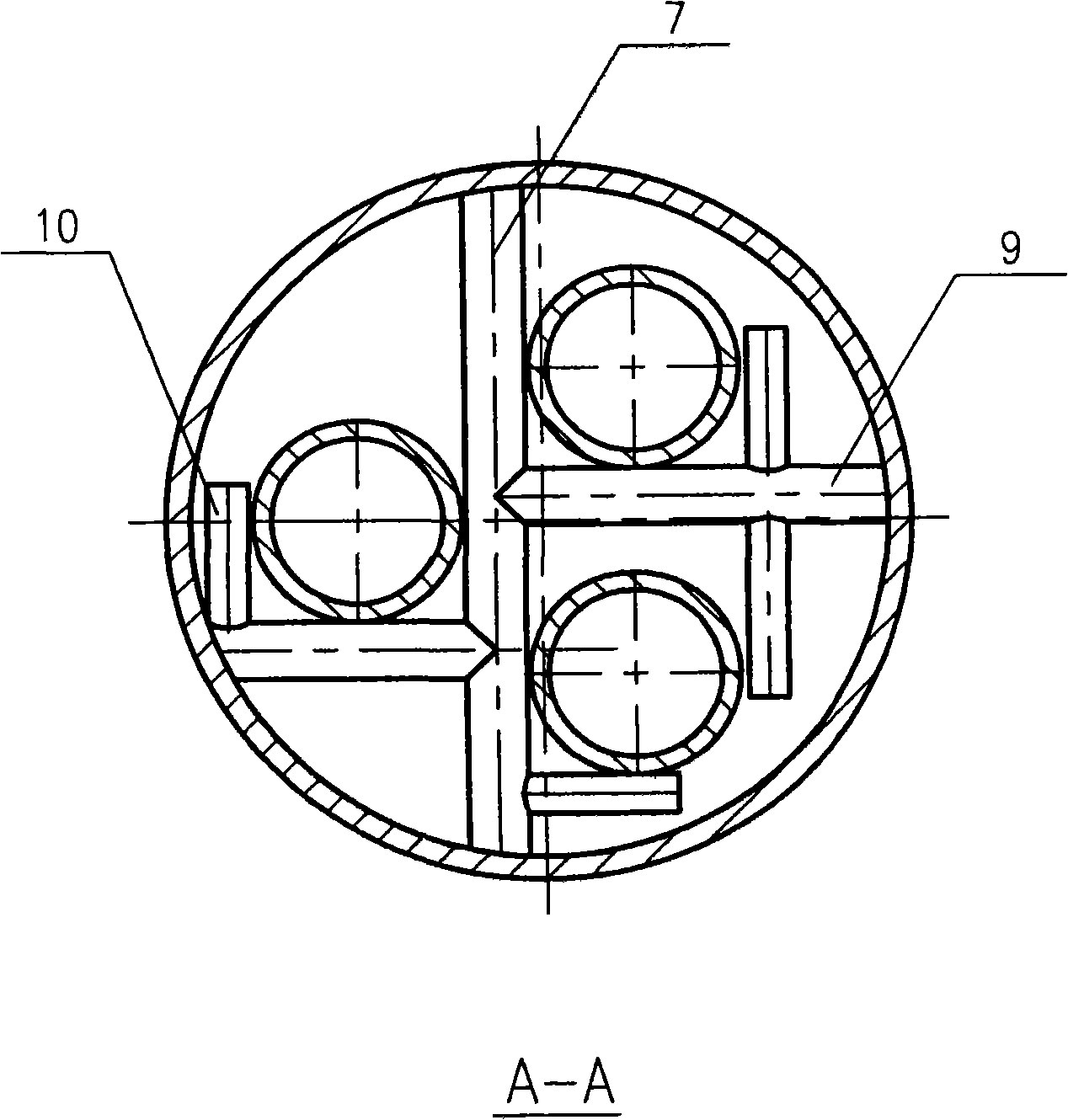

[0020] Embodiment 2 Small short tube fixed star casing preheater

[0021] like figure 1 and 3 shown. Take the steel pipe of φ610 as the outer casing 1 and press the two ends of the steel pipe figure 2 In the shown scheme, a bracket vertical tube 7 is welded on first, and then a bracket horizontal tube 9 is welded on both sides of the vertical tube to divide the inner space of the outer tube into three large and small parts, and then in the three large spaces Weld some small short pipes 10 for positioning the inner pipe on the corresponding positions on the vertical and horizontal pipes of the support. Do not allow it to roll or slip. The inner pipe is a steel pipe of φ219. In the assembled type, three inner tubes are first inserted into the bracket at one end of the outer tube and passed out from the bracket at the other end, and then the inner tube with the outer tube is welded in series. Since the inner pipe is longer than the outer pipe, the inner pipe can be welded ...

Embodiment 3

[0023] Embodiment 3 Small short tube and top frame combined fixed star-shaped casing preheater

[0024] like figure 1 and 4 shown. Take the steel pipe of φ610 as the outer casing 1 and press the two ends of the steel pipe figure 2 Shown scheme upper and lower each welds two bracket horizontal tubes 9, the distance between the two horizontal tubes can accommodate the inner tube to pass through, and then welds a short vertical tube 11 at the central part of the two horizontal tubes, and uses the short vertical tube Divide the space between the two support horizontal tubes into two, and then respectively weld a T-shaped top frame 8 on the inner wall of the outer tube on both sides of the short vertical tube, and in the upper space of the upper horizontal tube, use a horizontal The midpoint of the tube is the origin, and a T-shaped top frame 8 is welded on the corresponding position of the outer tube inner wall that is 120° before and after this point. The tube 2 passes freel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com