Graded wind-adjusting low NOX multi-fuel combustion device

A burner and co-firing technology, applied in the field of boiler combustion devices, can solve the problems of single fuel, insufficient fuel, waste, etc., and achieve the effects of strong adaptability, reduction of production volume, and reduction of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

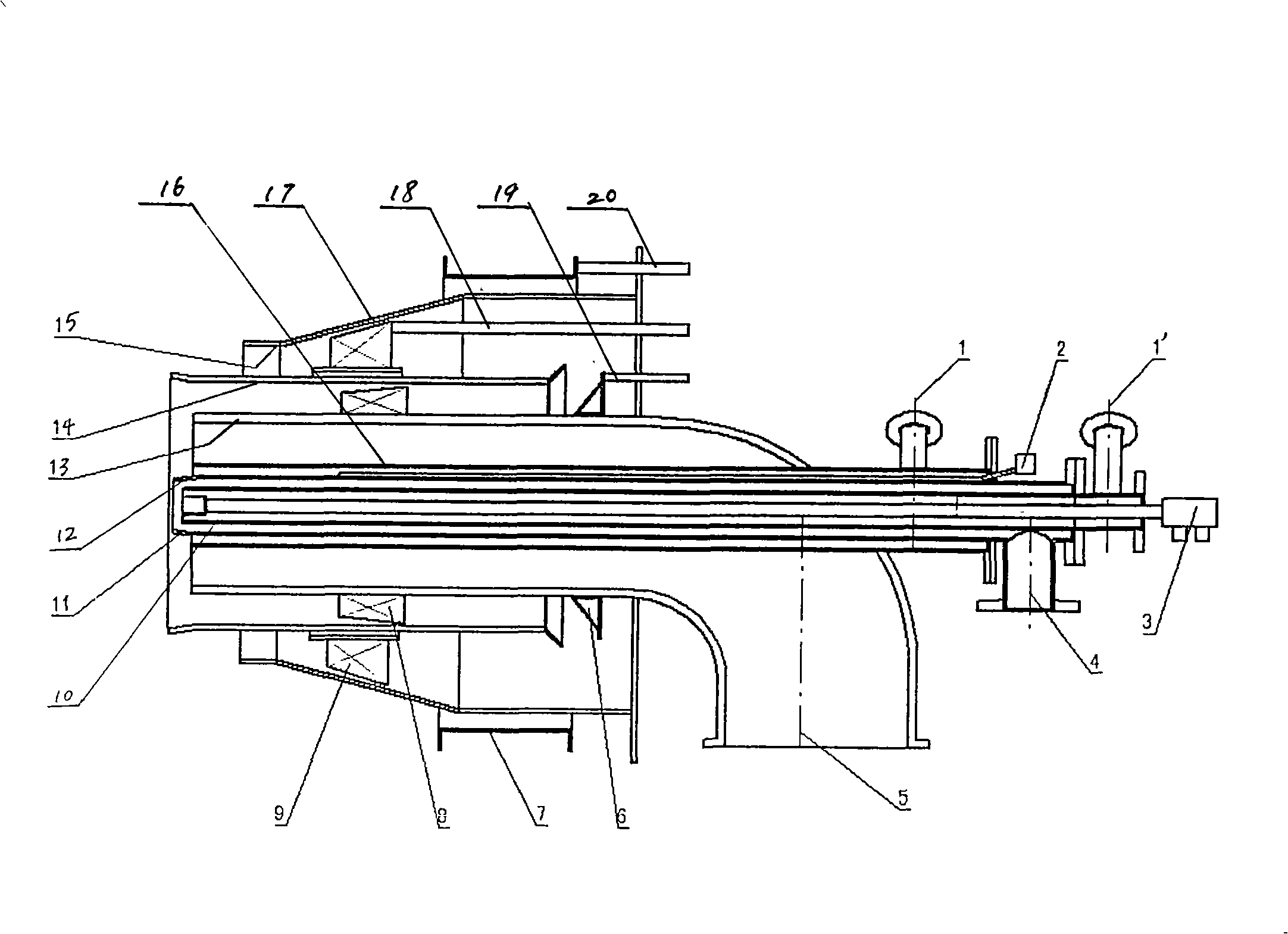

[0009] In the figure, the burner consists of primary air duct 10, secondary air duct 14, cold air duct 16, tertiary air duct 15, secondary air rotating blade 8, tertiary air adjustable rotating blade 9, oil gun tube 3, gas pipe 11. Composed of flame detector 3, pulverized coal pipe 13 and igniter 12; its feature is: the burner is composed of tubular primary air pipe 12, gas pipe 11, cold air pipe 16, pulverized coal pipe 13, and secondary air pipe 14 and the tertiary air duct 15 are set and fixed in the order of the coaxial centers; the tubular oil gun tube 3 is inserted into the port of the primary air duct 10 from back to front, and is flush with the port, and is fixed on the axis of the primary air duct 10. center; the tail ends of the primary air pipe 10 and the gas pipe 11 are respectively connected with the horizontal cold air inlet flange 16, the primary air inlet flange 1 and the gas pipe inlet flange 4; the pulverized coal pipe 13 is set on the cold air pipe 16 periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com