Production method and application of lithium niobate/III family nitride heterojunction ferroelectric semiconductor film

A nitride, heterojunction technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of limited development, difficult integration of ferroelectric oxides, and difficult handling of ferroelectric oxides, and achieves high performance. Battery life, the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

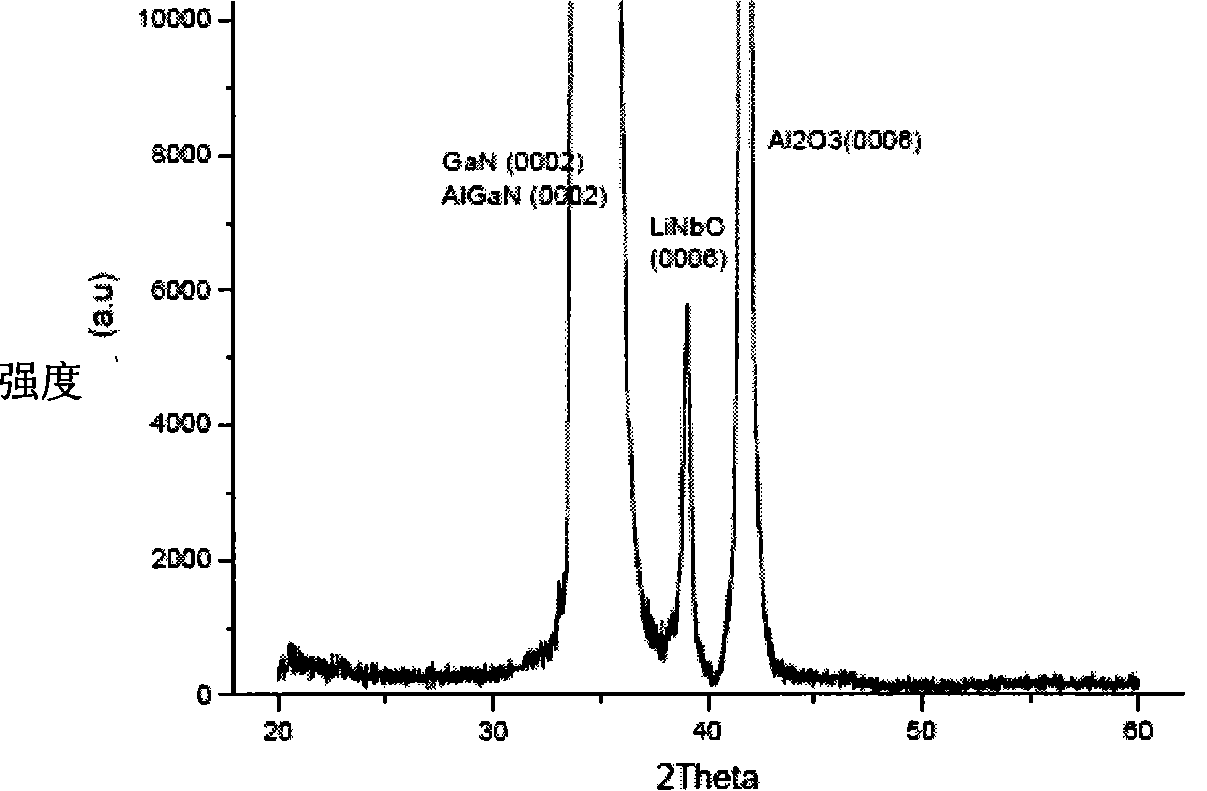

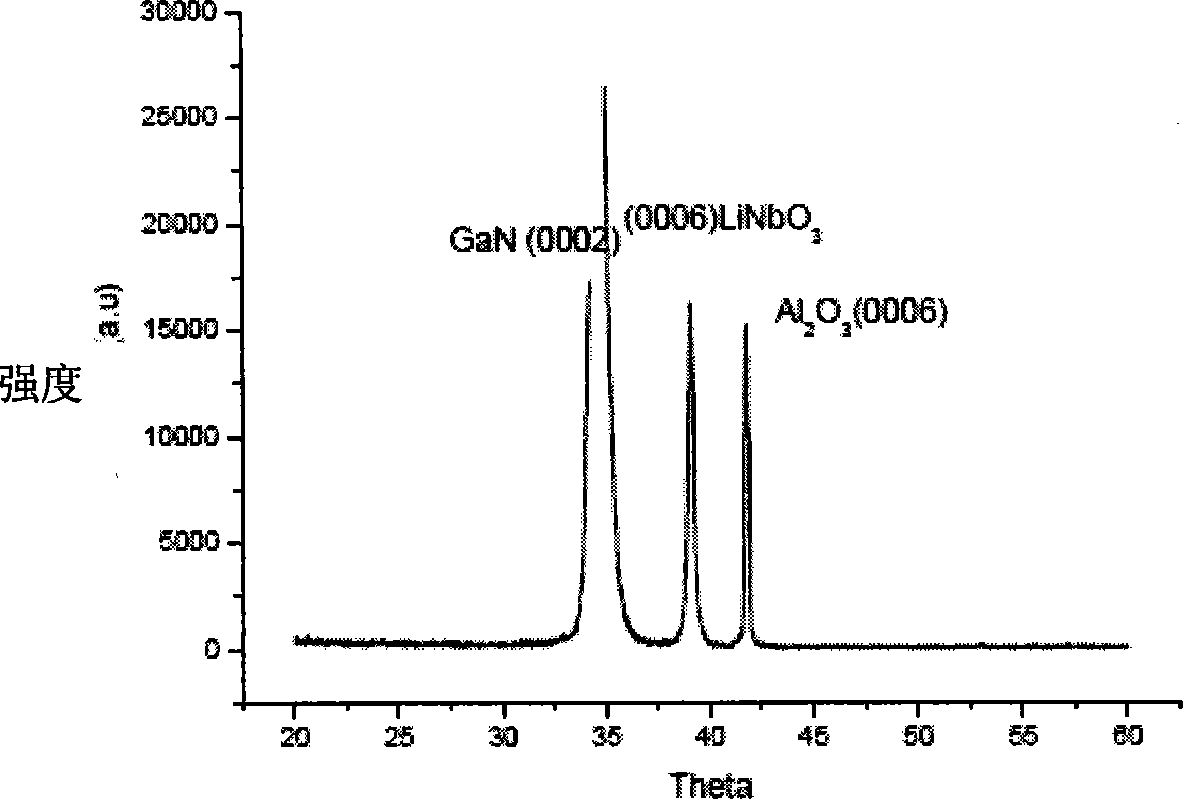

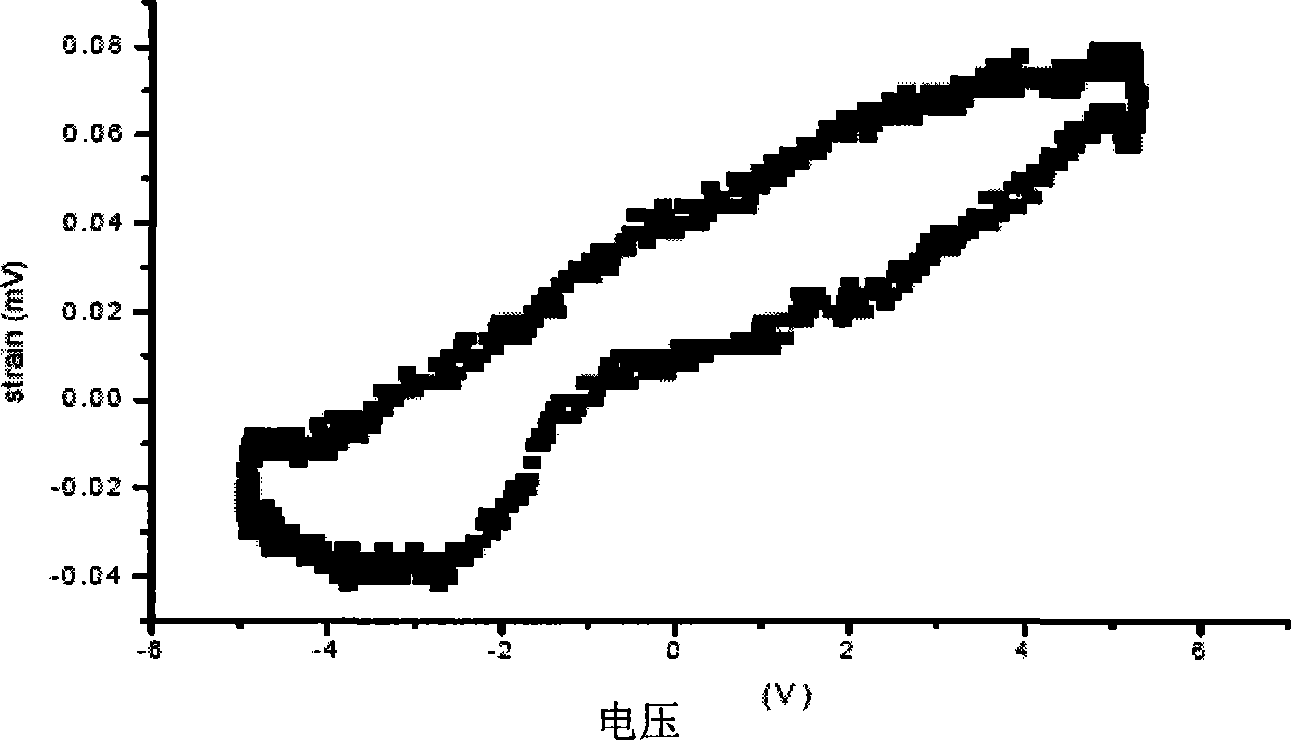

[0029] Using metal organic chemical vapor deposition (MOCVD) to grow group III nitride semiconductor heterostructure materials on (0001) plane sapphire substrates, including AlN / AlGaN, AlN / GaN and AlGaN / GaN heterostructure materials as buffers layers or composite substrates. Through the optimal control of growth conditions such as pulsed laser deposition (PLD) reaction chamber vacuum, growth temperature, and laser energy, the use of high-purity 5N LiNbO 3 Bulk material was used as the target, and high-quality LiNbO was obtained on AlGaN / GaN heterostructure composite substrates by pulsed laser deposition (PLD) 3 film. Then, devices with various functional structures are prepared on the heterostructure thin film through semiconductor device technology.

[0030] 1) AlN / AlGaN, AlN / GaN or AlGaN / GaN heterostructure composite substrates are grown on (0001) plane sapphire substrates by metal organic chemical vapor deposition (MOCVD). Group III nitride semiconductor heterostructure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com