Suction nozzle and surface mounting machine

A technology of adsorption surface and nozzle seat, applied in the direction of electrical components, electrical components, etc., to achieve the effect of easy cleaning operation, reduced operation frequency, and shortened cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

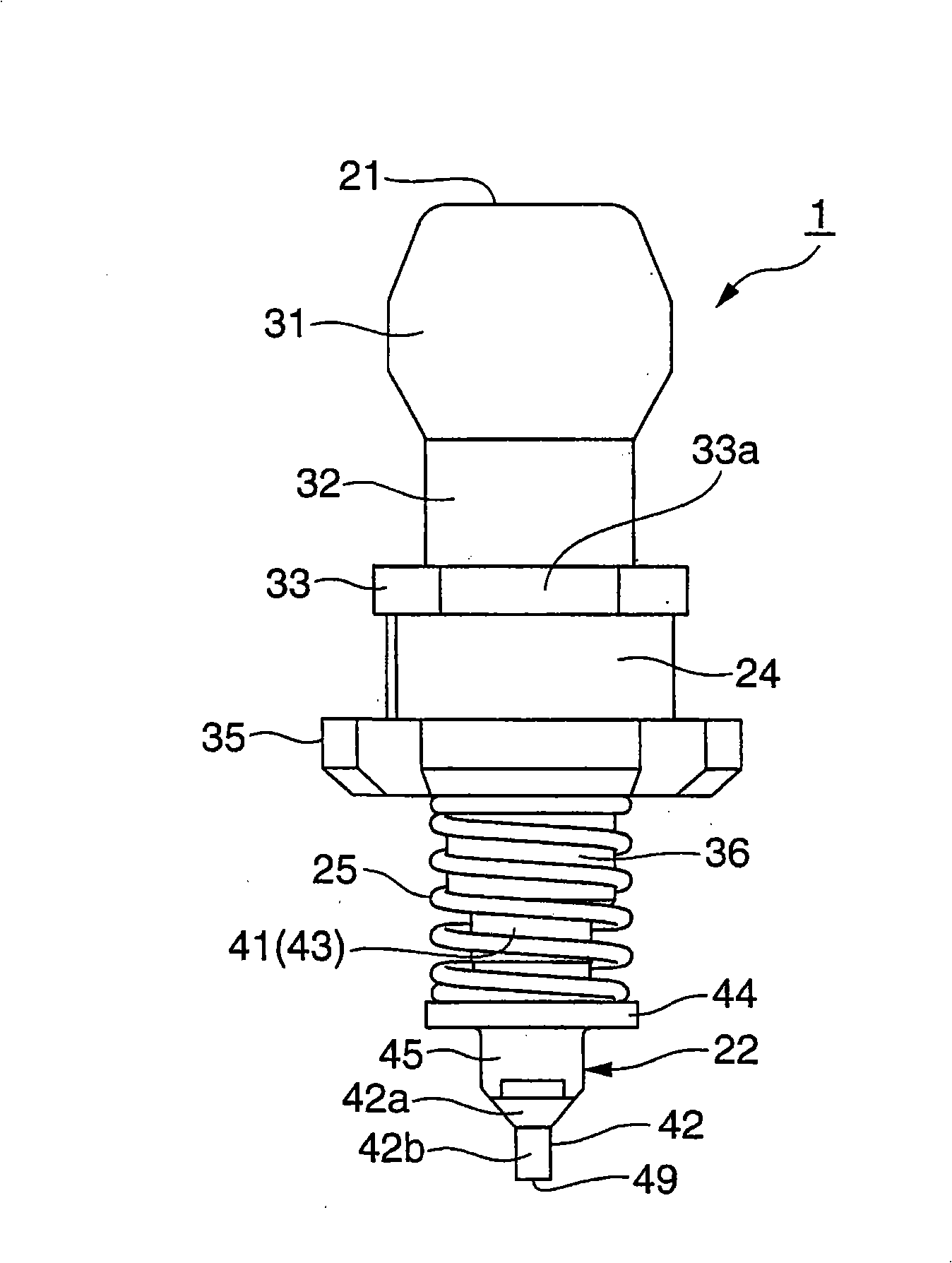

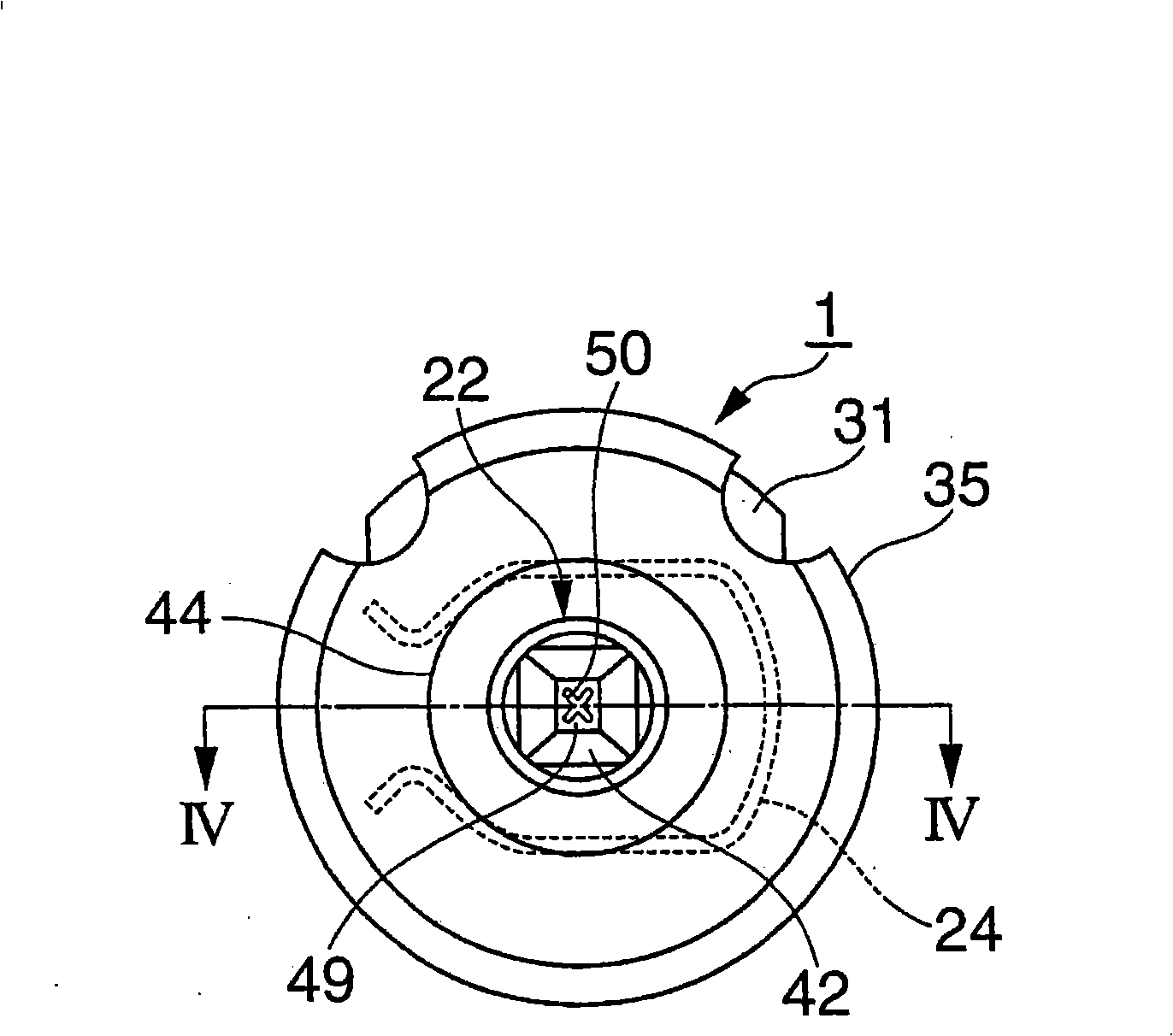

[0038] Below, combine Figure 1 to Figure 14 , and an embodiment of the suction nozzle according to the present invention will be described in detail.

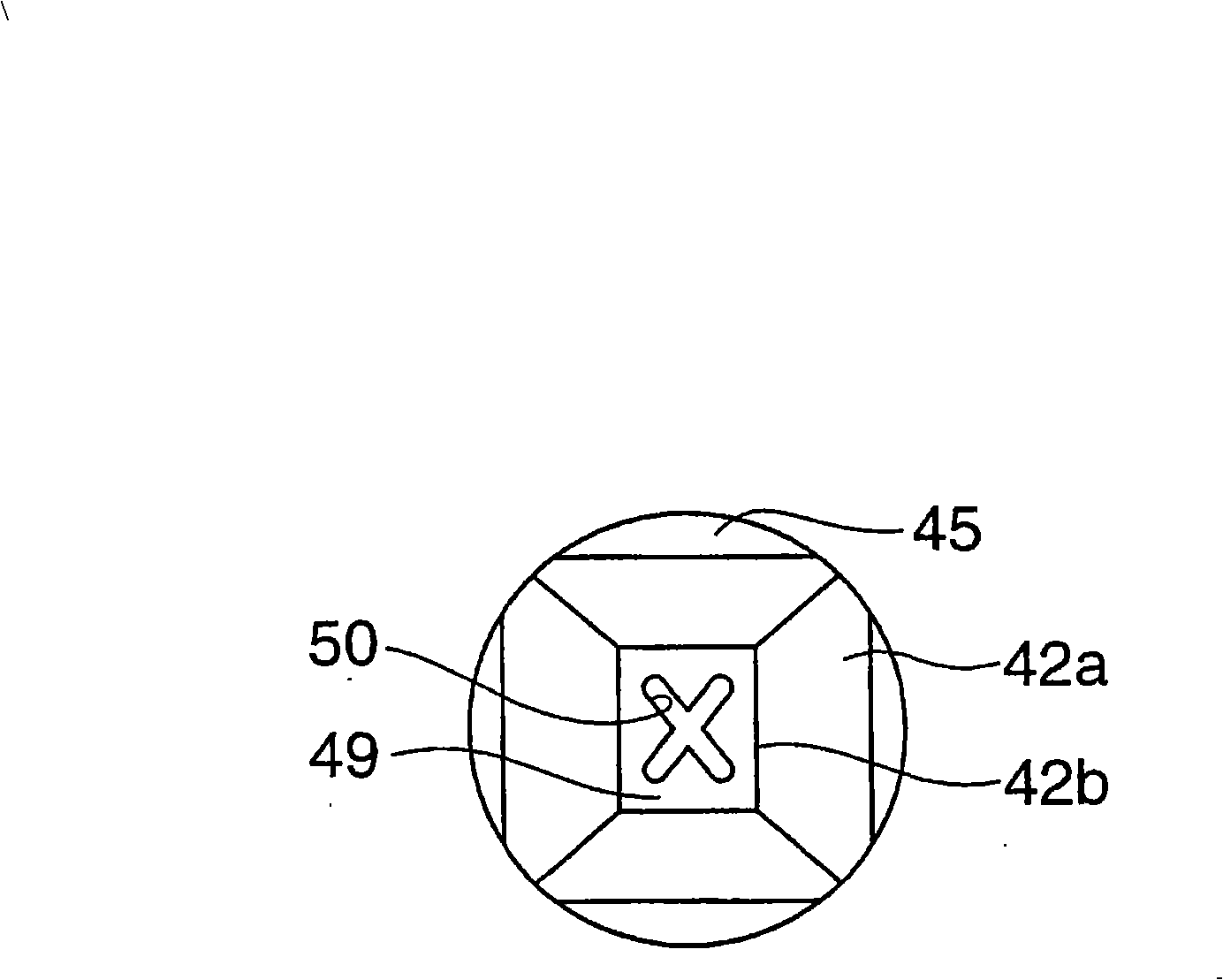

[0039] figure 1 is a side view of the suction nozzle related to the present invention, figure 2 is the bottom view of the nozzle, image 3 is an enlarged view of the component adsorption surface, Figure 4 is a longitudinal sectional view of a suction nozzle related to the present invention, and is figure 2 Sectional view of line IV-IV.

[0040] Figure 5 is a schematic diagram of the clamping part, where (a) is a top view, and (b) is a side view. Image 6 (a) is a side view, (b) is a bottom view, (c) is a C-C line sectional view of (b), and (d) is a D-D line sectional view of (a). Figure 7 It is a schematic diagram of a suction nozzle main body, (a) of this figure is a side view, (b) is a B-B line cross-sectional view of (a).

[0041] Figure 8 It is a perspective view of a suction nozzle related to the present in...

no. 2 Embodiment approach

[0100] Suction nozzles can also be formed as Figure 15 Nozzle shown.

[0101] Figure 15 It is a cross-sectional view showing another embodiment of the suction nozzle. exist Figure 15 ,and Figure 1 to Figure 14The same or equivalent components as those described in the illustrated embodiments are denoted by the same reference numerals, and detailed description thereof will be appropriately omitted.

[0102] Figure 15 In the shown nozzle 1 , the elongated hole 51 serves as an engaging portion of the nozzle body side 22 engaged with the pin 23 . That is, on the shaft member 41 of the nozzle main body 22 of this embodiment, at the position corresponding to the pin hole 37 of the nozzle holder 21, a long shaft is formed that is long in the vertical direction (the axial direction of the nozzle holder 21). Hole 51.

[0103] The elongated hole 51 is passed through the fitting cylinder 43 of the nozzle body 22 in a state of penetrating the fitting cylinder 43 in a direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com