Drying treatment production line and method for circulating water slime

A circulating water and production line technology, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of low automation of circulating water purification devices and safety of circulating water Hidden dangers, poor purification effect and other problems, to achieve the effect of reducing energy consumption, reducing sediment content, and complete precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that the following detailed description is exemplary and intended to provide further explanation of the present invention. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

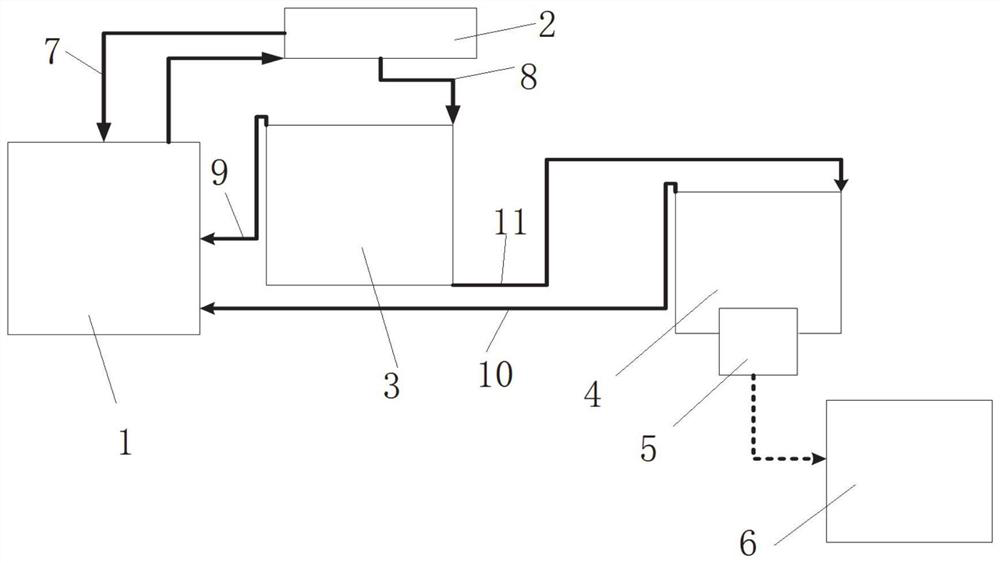

[0029] In a typical embodiment of the present invention, such as figure 1 As shown, a drying treatment production line for circulating water sludge is proposed, including cooling tower 1, cellulose filter 2, sludge sedimentation tank 3, centrifugal sludge drying equipment 4, dry sludge transportation equipment 5, dry sludge Incineration equipment6.

[0030] Wherein, the cooling tower 1 and the cellulose filter 2 are communicated by a delivery pipeline, and the delivery pipeline is provided with a delivery pump, so that the circulating water is delivered from the cooling tower to the cellulose filter.

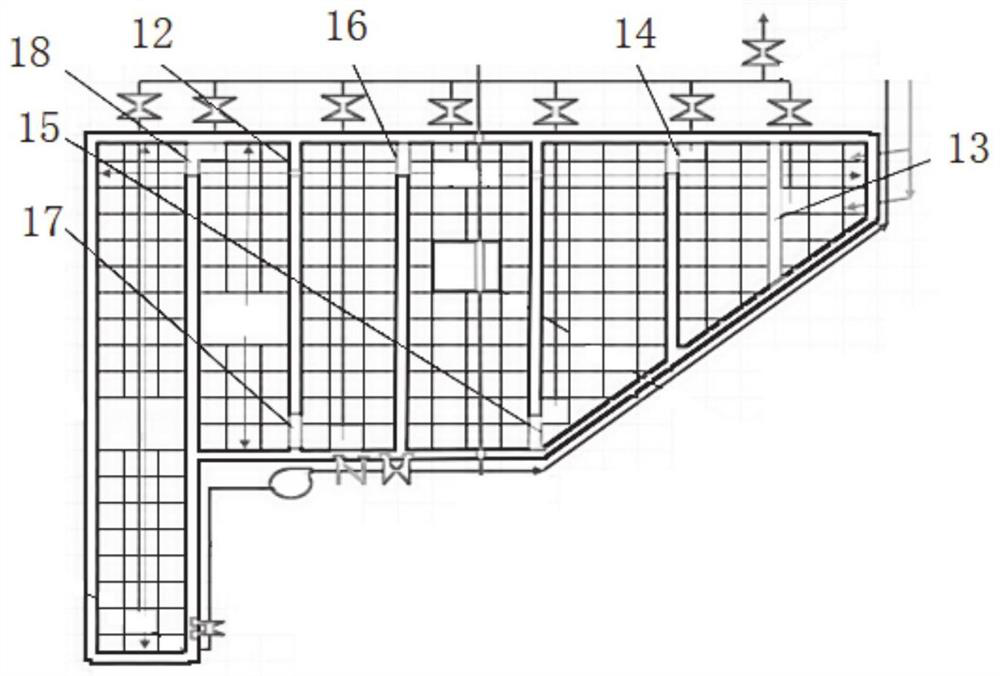

[0031] The cellulose filter 2 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com