Gold blocking coating process

A coating process, bronzing film technology, applied in decorative arts, printing processes, processes used to produce decorative surface effects, etc., can solve problems such as affecting the appearance of products, damaging the bronzing pattern, and not being able to bump the bronzing pattern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

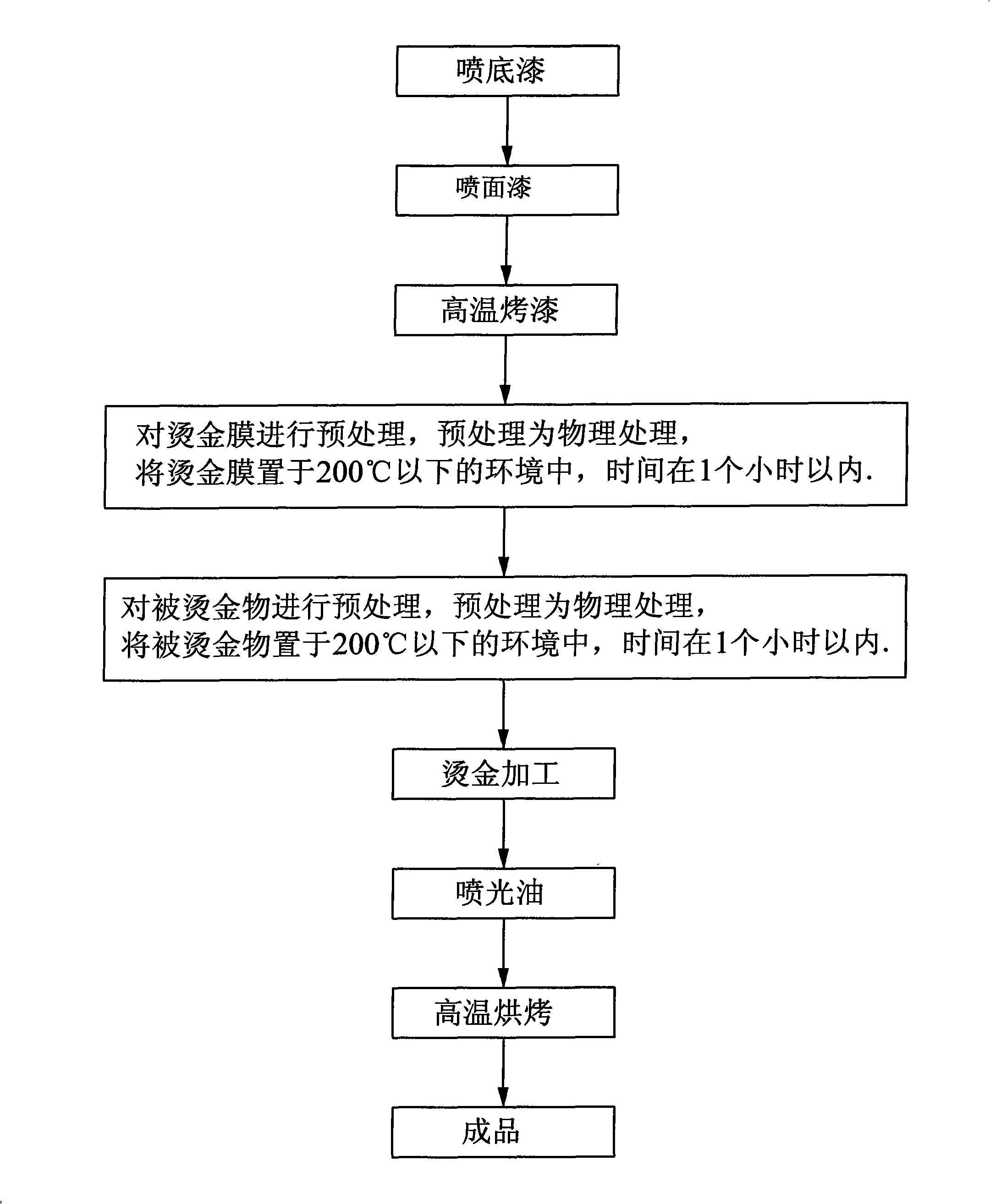

[0018] A hot stamping coating process, see attached figure 1 , which consists of the following steps,

[0019] Step 1, spray primer, spray a layer of primer on the metal surface of the gilded object, whether this step needs to be determined by the surface roughness of the gilded object, the primer is used to fill the metal material of the gilded object Potholes on the surface make up for the defects of the substrate, making the surface of the metal material to be gilded smoother, preparing for the subsequent spraying of topcoat and gilding, so that it can process higher-quality gilding effects;

[0020] Step 2, spray topcoat, spray a layer of topcoat on the surface of the metal material of the bronzing object, the color of the topcoat is the surface color of the bronzing object;

[0021] Step 3, high-temperature baking paint, the temperature of baking paint is 150-200°C, and the time is 15-30 minutes;

[0022] The 4th step, carry out pretreatment to bronzing film, and pretre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com