Plasma chemical vapor deposition vacuum apparatus for photovoltaic assembly scale manufacture

A chemical vapor deposition, plasma technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of low pass rate, increase the production line process, unstable electrode radio frequency glow, etc. To achieve the effect of reducing manufacturing costs, reducing the number of equipment, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

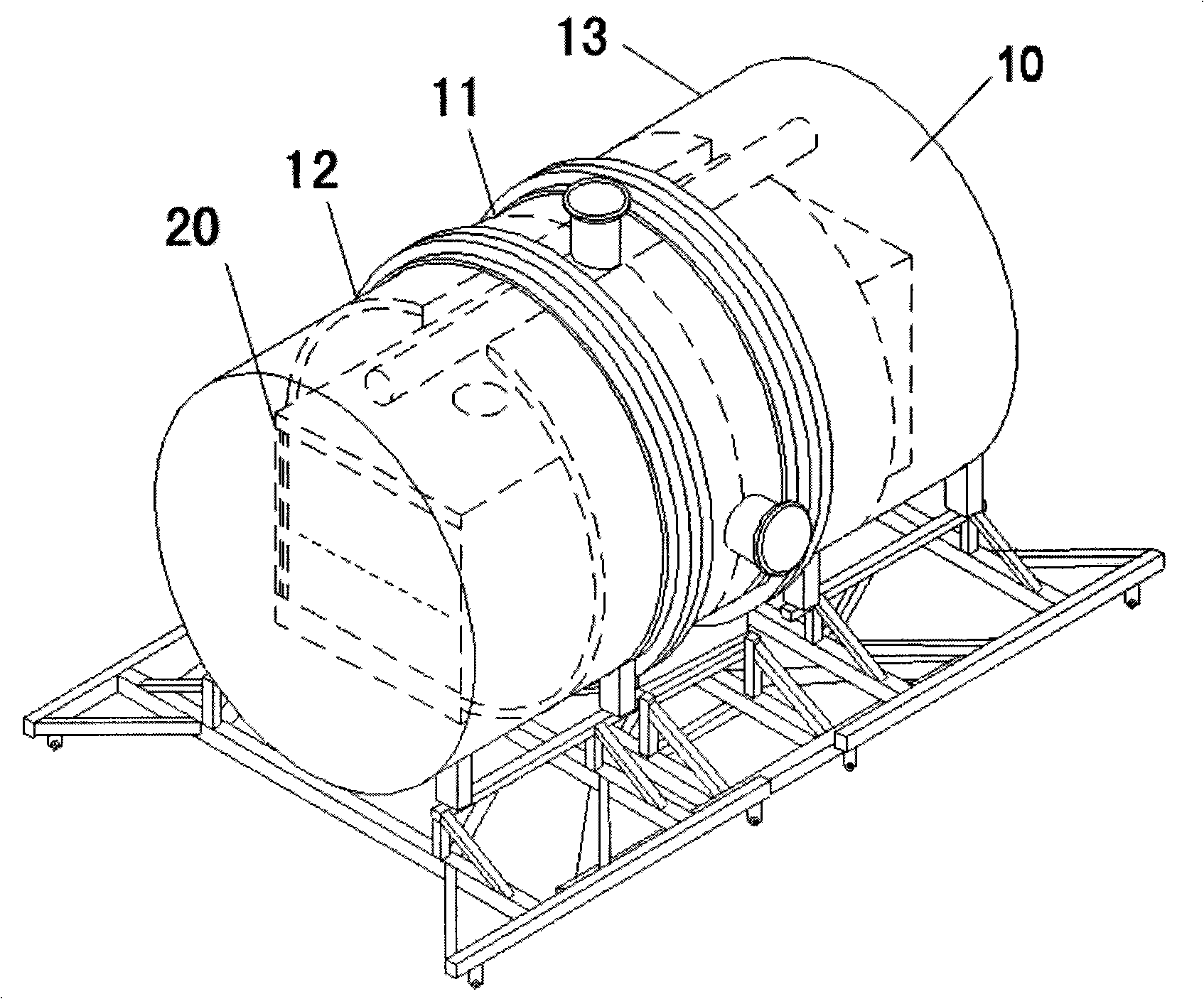

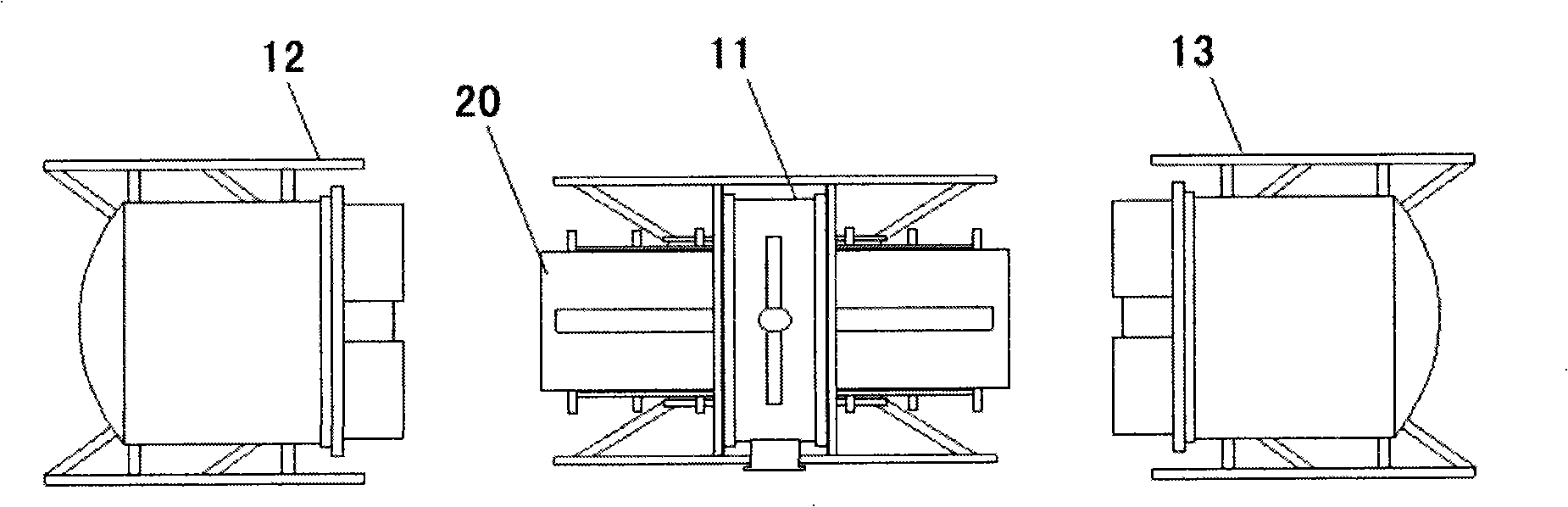

[0022] Such as figure 1 , figure 2 As shown, a plasma chemical vapor deposition vacuum equipment for large-scale manufacturing of photovoltaic modules includes a vacuum chamber 10 and an electrode box 20 .

[0023] refer to figure 2 , The vacuum chamber 10 is a detachable vacuum chamber, which includes a relatively fixed main body portion 11 located in the middle section and detachable portions 12, 13 respectively located at both ends. The main body 11 and the detachable parts 12 and 13 at both ends can be sealed to form a vacuum chamber when required for work, and can also be separated when loading and unloading deposited products.

[0024] refer to figure 1 , figure 2 , the electrode box 20 is installed in the vacuum chamber 10 , and remains relatively stationary with the main body 11 of the vacuum chamber 10 before, during and after deposition.

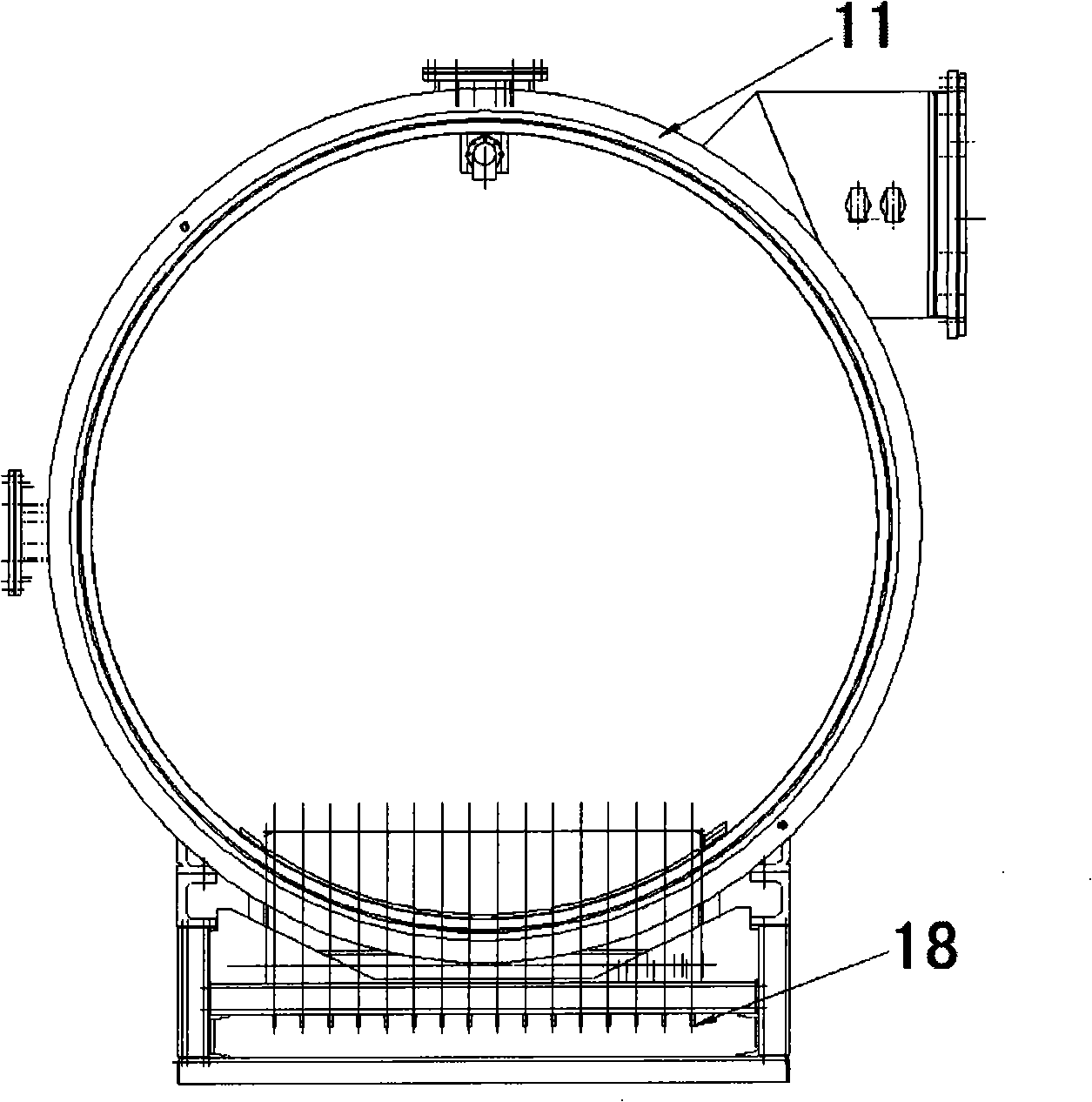

[0025] Such as image 3 As shown, the main body 11 of the vacuum cavity 10 is provided with a radio frequency introducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com