Shielding and earthing structure of flexible circuit board

A flexible circuit board and grounding structure technology, applied in the fields of magnetic field/electric field shielding, printed circuit components, electrical components, etc., can solve the problems of long process flow, low manual efficiency, and unsatisfactory shielding effect, and achieve enhanced reliability. performance and electrical performance, and the effect of improving the connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

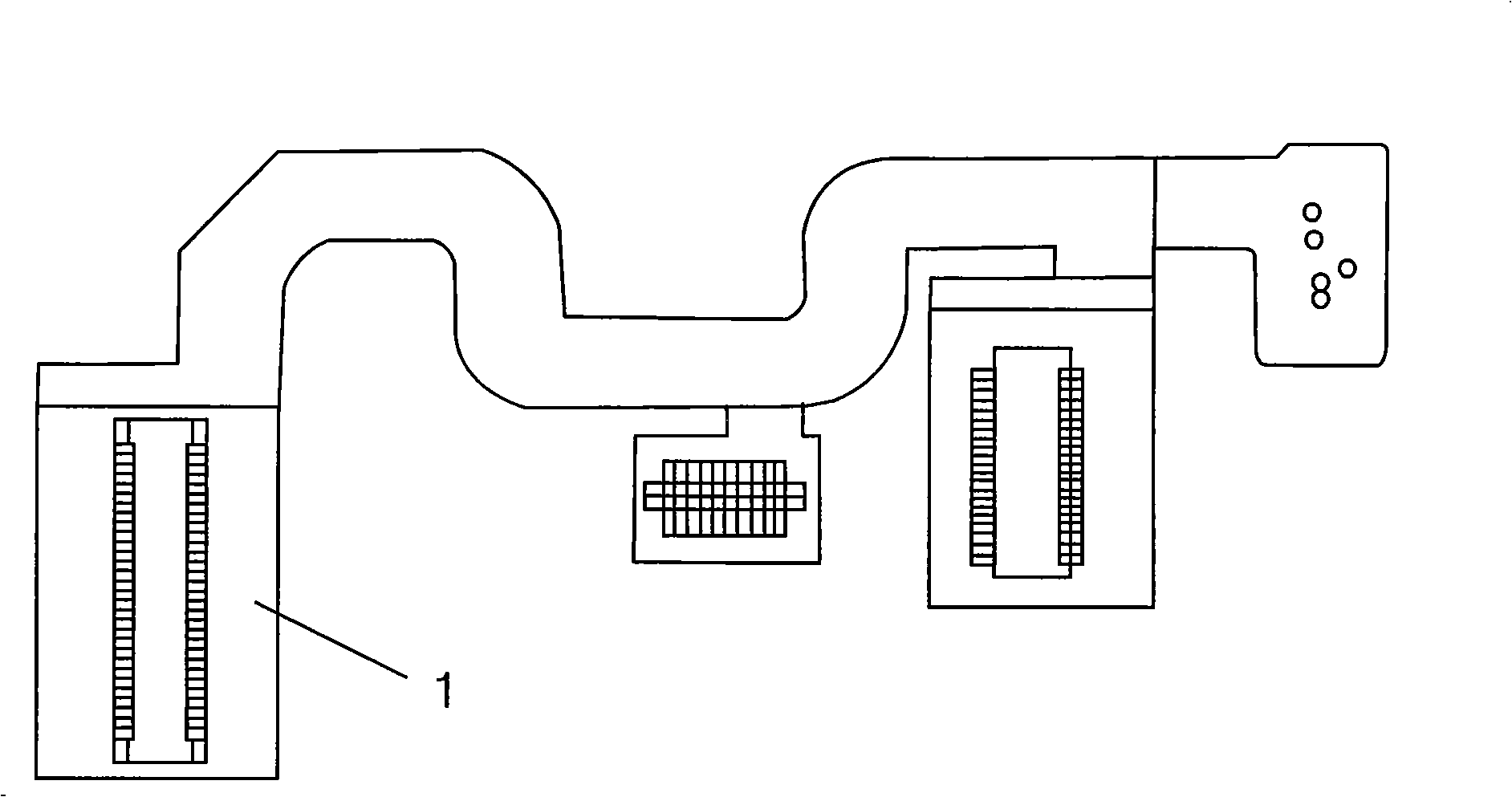

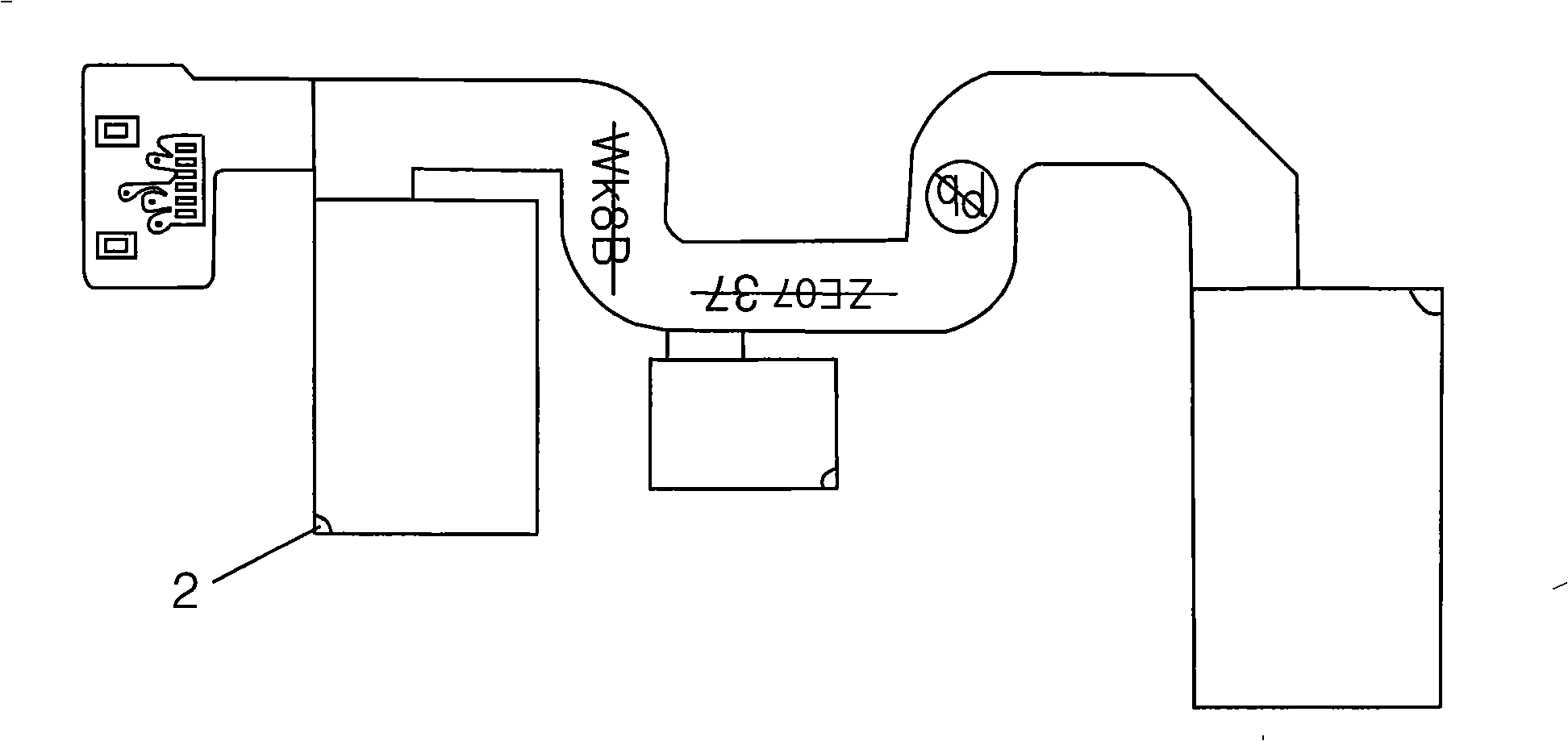

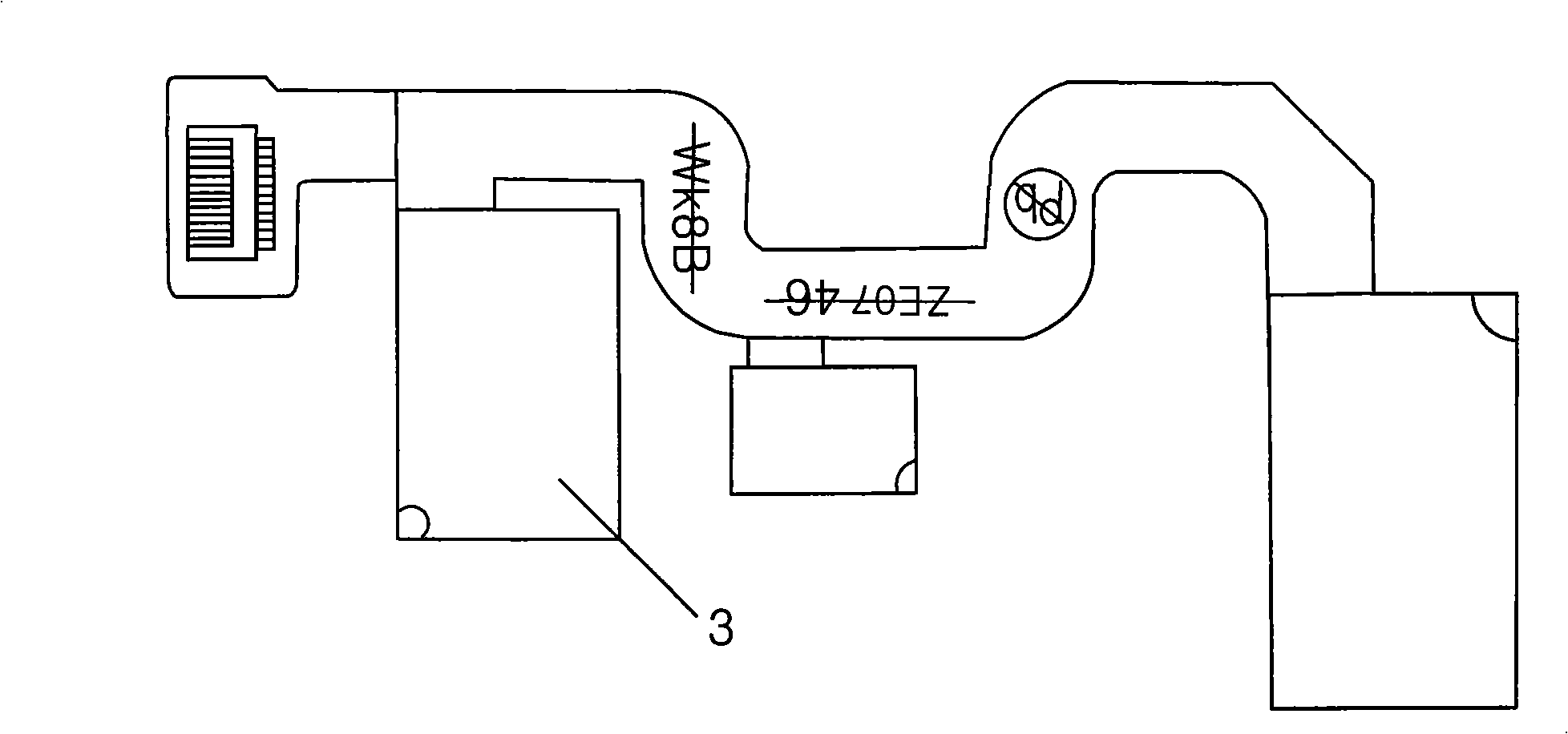

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Such as figure 1 and diagram 2-1 , 2-2 As shown, the shielding and grounding structure of the flexible circuit board of the present invention includes the main board 1 of the flexible circuit board, and the grounding copper skin 2 is compounded on the main board 1 through a high-temperature adhesive film, and the grounding copper skin 2 is gold-plated and tinned Finally, a grounding structure is formed, and a conductive shielding film 3 is pressed at a designated position of the main board. Such as Figure 4 As shown, the conductive shielding film of the present invention is composed of an outer release protective film 11, an insulating material 12, a conductor 13, a conductive adhesive 14 and an inner release protective film 15 stacked from top to bottom, and the color can be black or silver. . According to the customer's demand range, add a shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com