Plastic core-rubber-tire trucks for crossheading

A technology of transport vehicles and rubber wheels, which is applied in the direction of goods transport vehicles, vehicles for freight, transport objects, etc., can solve the problems of backward technology and other problems, and achieve the effects of low transportation cost, strong climbing ability and narrow vehicle body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

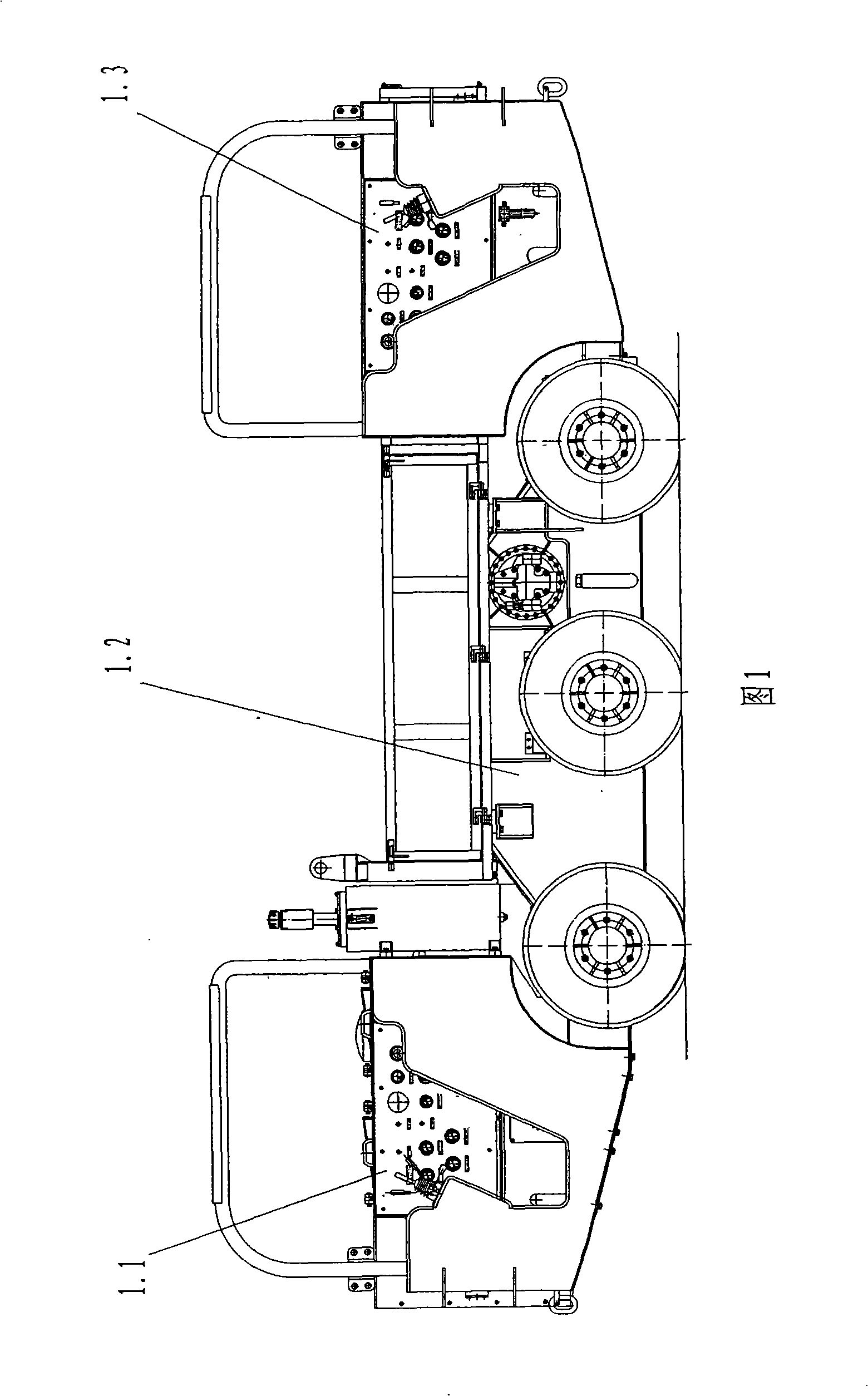

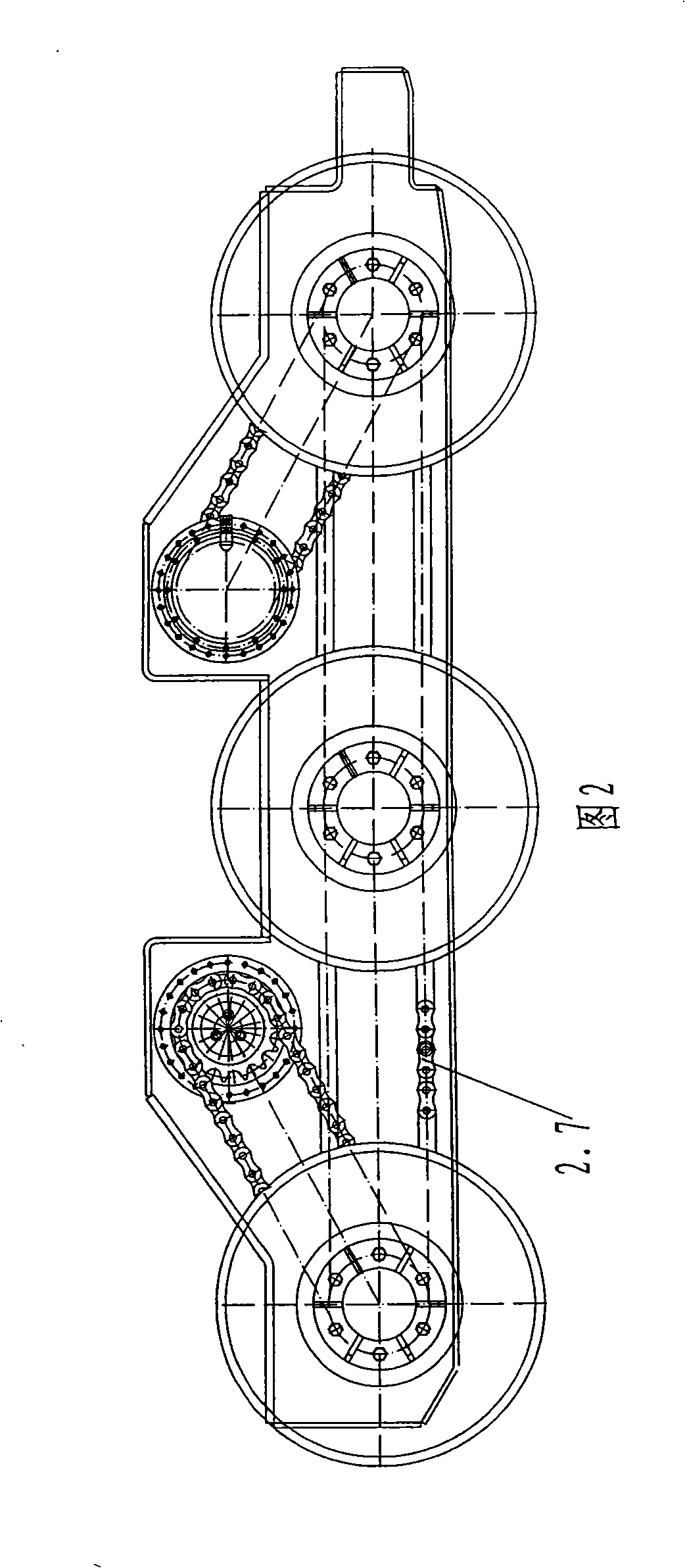

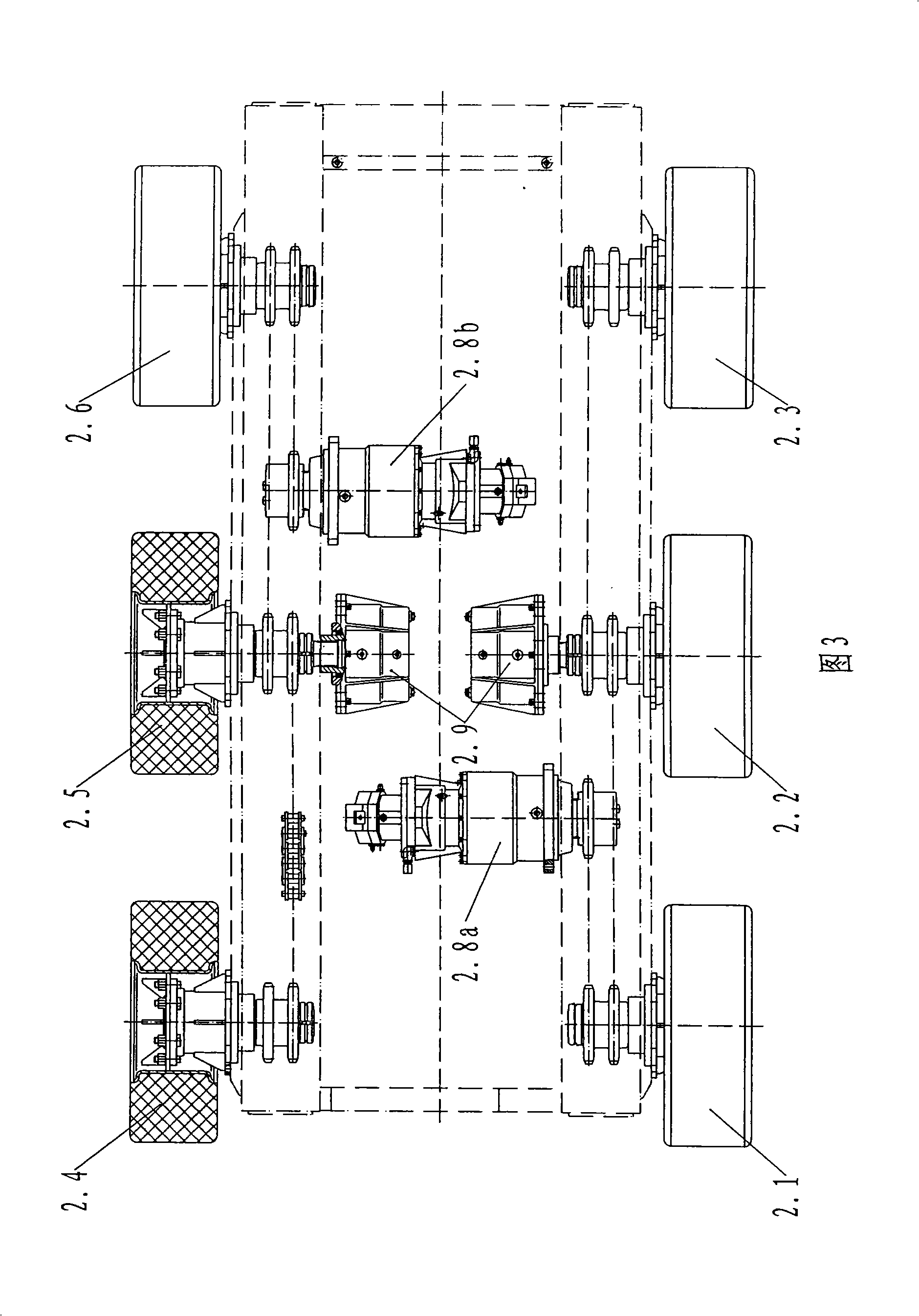

[0021] The invention uses an explosion-proof diesel engine as power, adopts an integral rigid welded frame, hydraulic mechanical transmission, 6×6 all-wheel drive, two-way driving in both sides of the cab, full hydraulic control, skid steering, and the service brake is back pressure braking. , The parking brake is a wet brake, and the three-door flat knife-shaped cargo box is equipped with a Perkins four-cylinder diesel engine, an intake and exhaust explosion-proof system, and the engine is started by an air motor, which is safe and reliable in explosion-proof. The whole vehicle adopts a pneumatic safety protection system, which is protected by sensors.

[0022] 1. Vehicle type

[0023] The whole vehicle adopts an integral rigid welded frame, powered by an explosion-proof diesel engine, hydraulic mechanical transmission, 6×6 all-wheel drive, two-way driving with double cabs, full hydraulic control, skid steering, and pneumatic start and protection.

[0024] 2. Engine device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com