Flow guide and ultraviolet disinfecting reactor

A technology of ultraviolet disinfection and deflector, applied in the direction of light water/sewage treatment, etc., can solve the problem that the sterilization efficiency needs to be further improved, and achieve the effect of being easy to implement and popularize, easy to process and manufacture, and to increase the number of kills.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

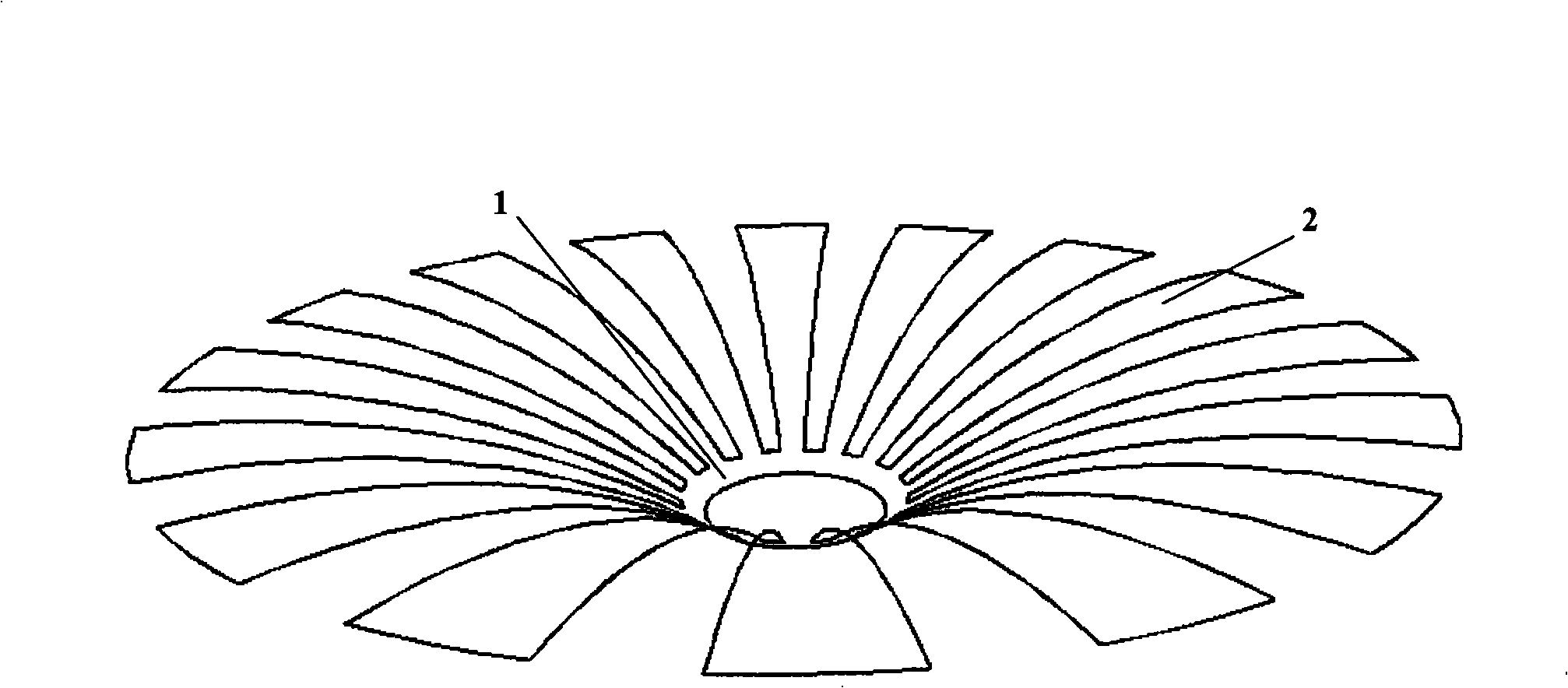

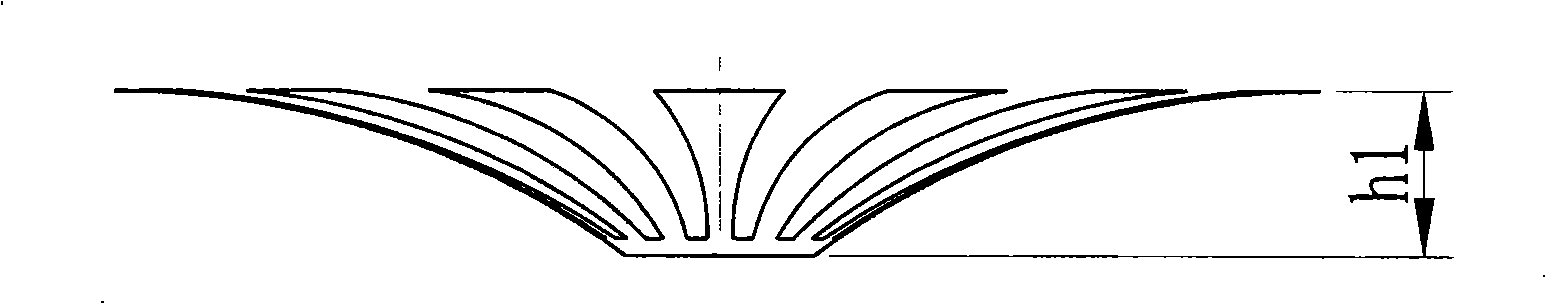

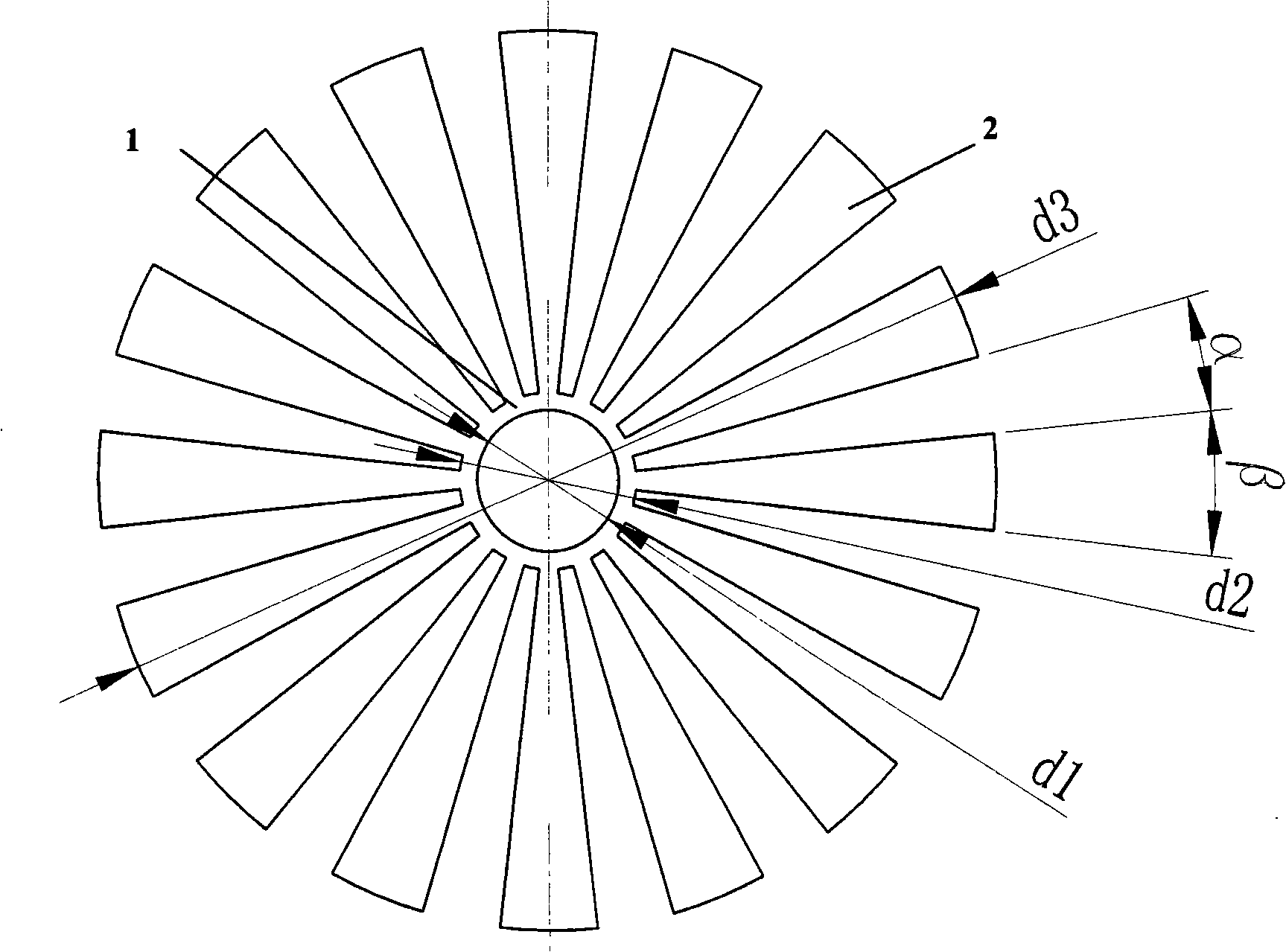

[0023] In this embodiment, the deflector is stamped and formed with stainless steel sheet, and its shape and structure are as follows figure 1 , figure 2 , image 3 As shown, it is composed of an upwardly curved arc ring 1 and sixteen arc-shaped pieces 2 with the same axial bending radius as the arc-shaped ring. The axial bending radius R of the arc-shaped ring 1 and the arc-shaped piece 2 is 36.0mm, The height h1 of the deflector 8 is 7.0 mm. The horizontal projection of each arc-shaped piece 2 is a partial ring, and its central angle β is 12.5°, and the central angle α of each arc-shaped piece 2 is evenly distributed along the periphery of the arc ring 1 and is an integrated structure with the arc ring. α is 10°. In the deflector, the inner diameter d1 of the circular arc ring 1 is 8.0 mm, the outer diameter d2 of the horizontal projection of the circular arc ring is 10.0 mm, and the diameter d3 of the horizontal projection of the arc-shaped piece is 50.8 mm.

Embodiment 2

[0025] In this embodiment, the structure of the ultraviolet disinfection reactor is as Figure 4 As shown, the shell 3, the shell cover 4 installed on the upper end of the shell, the ultraviolet lamp tube 9 installed on the shell cover and located in the shell, the lamp limiting spring 6 fixed on the inner wall of the shell and the shell cover 3 consists of a deflector 8 inside. The inner diameter of the housing 3 is D88.9mm and the height is 227mm. The water inlet at the bottom of the housing 3 is connected to the water inlet pipe 7, and the water outlet on the side wall of the housing 3 is connected to the water outlet pipe 5. The inner diameter d0 of the water inlet pipe 7 is 21.4mm, the inner diameter of the outlet pipe 5 is 22.0mm; the distance H between the lower end of the ultraviolet lamp tube 4 and the bottom of the housing 3 is 17mm; the deflector 8 has the shape, structure and size described in Example 1, and is installed in the ultraviolet lamp Below the tube 9 and abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com