High wear resistant heddles

A technology of heald and heald rod, which is applied in the directions of heald, textile, textile and papermaking, etc., can solve the problems of bad influence of loom work, inconvenient manufacture of heald, falling off of metal wire, etc. The effect of broken yarn and reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

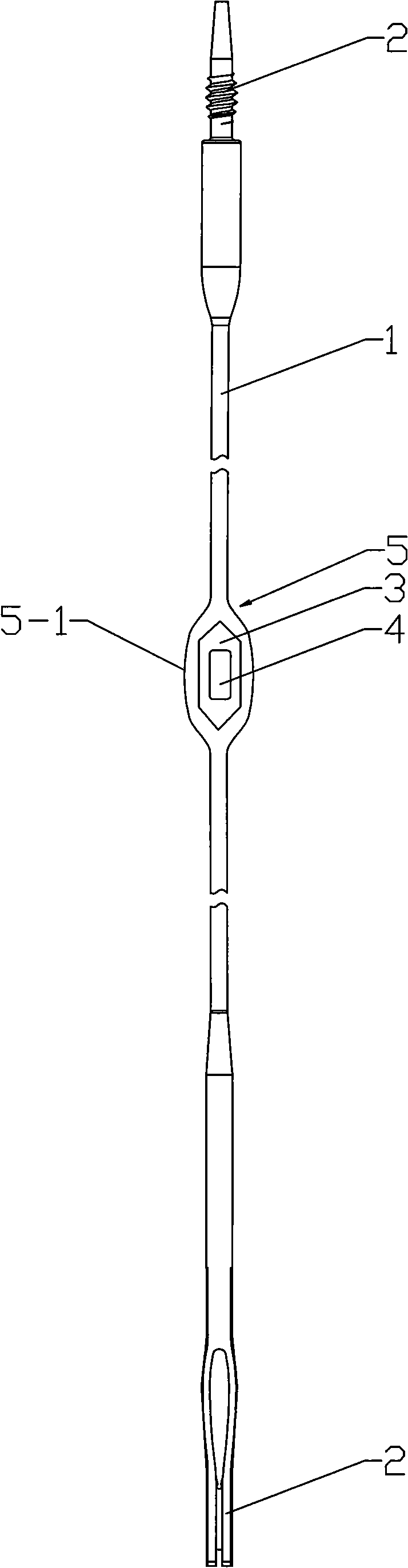

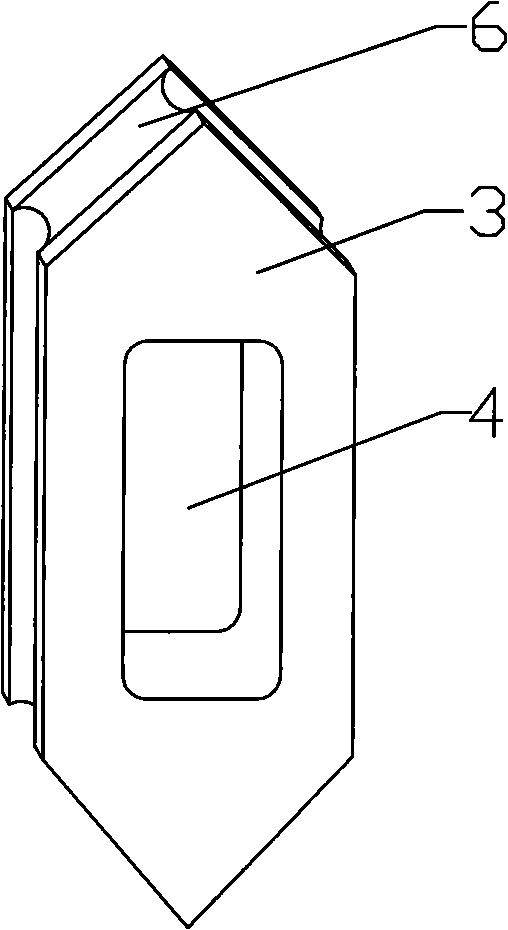

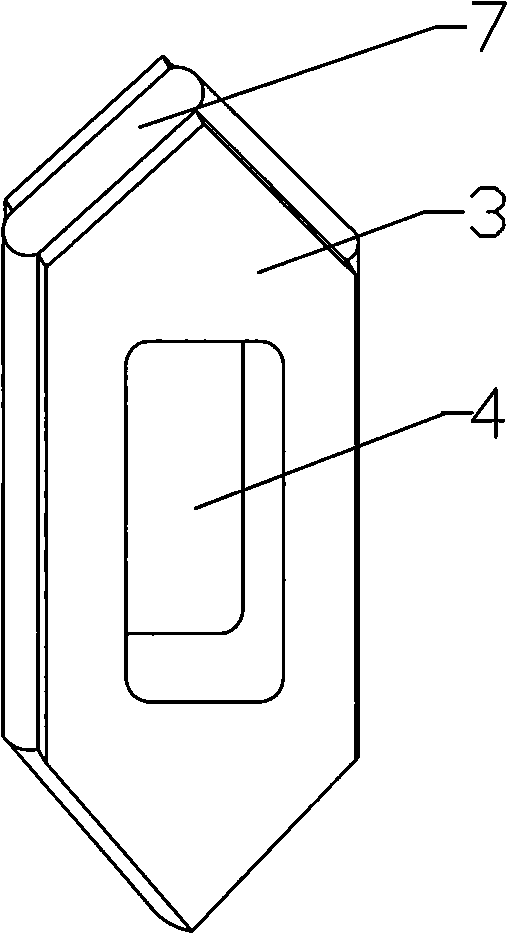

[0024] combine figure 1 , figure 2 As shown: the high wear-resistant heald of this embodiment includes: the two ends of the heald rod 1 are provided with connectors 2, the heald rod is provided with a heald eye, the heald eye is a porcelain eye 3, and a smooth wire threading hole is arranged in the porcelain eye. eye hole 4. The heald screw rod is a plastic heald screw rod 1, and the porcelain eye 3 is fixedly connected with the plastic heddle screw rod 1 by insert injection molding, and the outer edge surface of the wire eyelet 4 is a smooth surface 5. The periphery of porcelain eye 3 is in concave shape 6, and the porcelain eye is fixed in the plastic heddle rod by insert injection molding, and the outer edge surface of the threading eye hole is a smooth plastic surface 5-1 wrapped around the porcelain eye.

[0025] Because the heald screw rod is a plastic heald screw rod, the heddle wire of the present invention will not get rusty. Because the heald eye is a porcelain e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com