Controllable type permanent magnetism magnetic suspension vibration damping spring with air damping cavity

An air damping and vibration damping spring technology, applied in the directions of magnetic springs, springs, springs/shock absorbers, etc., can solve the problems of limited vibration damping effect and inability to adjust characteristics of objects, and achieve the effect of improving control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

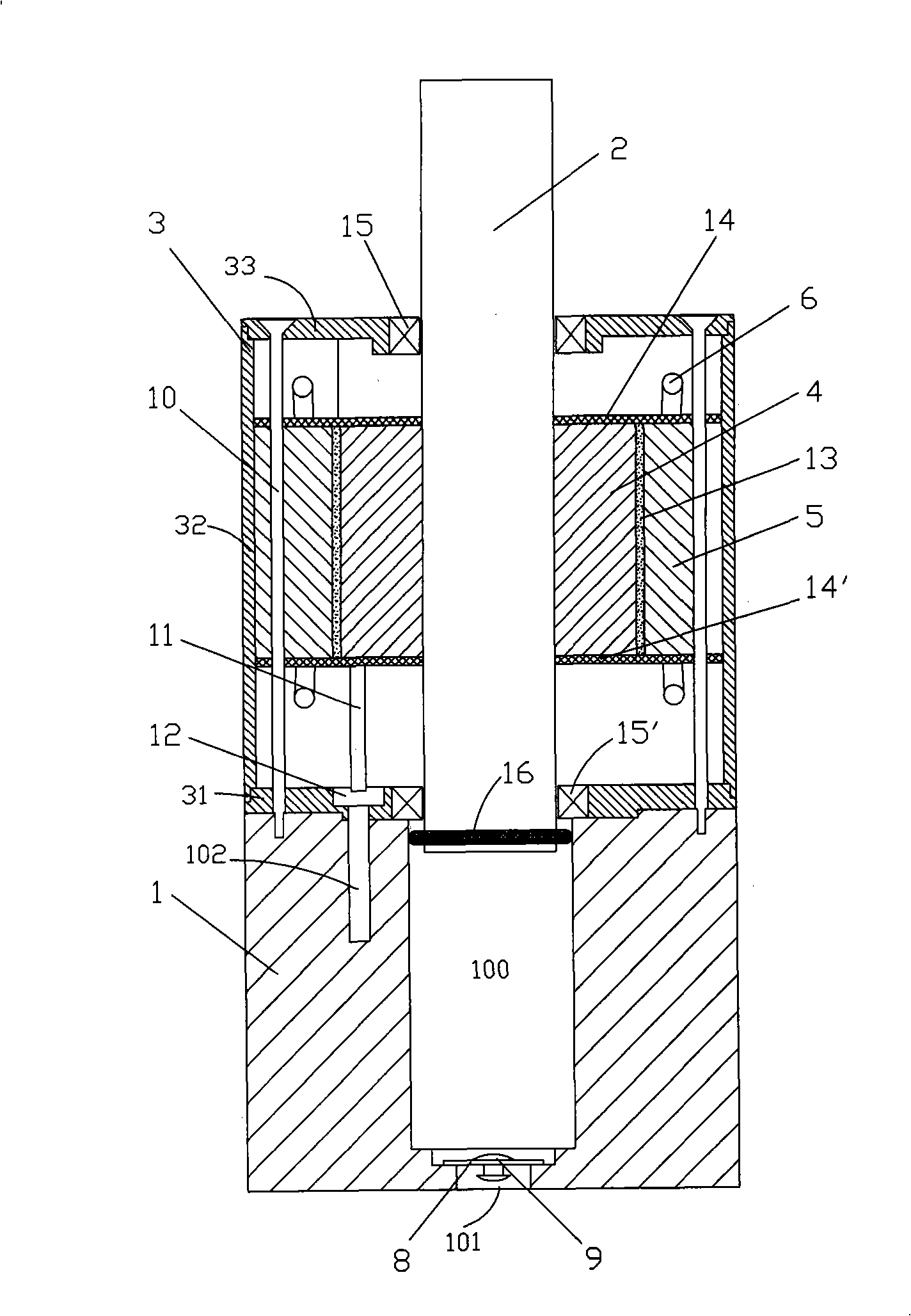

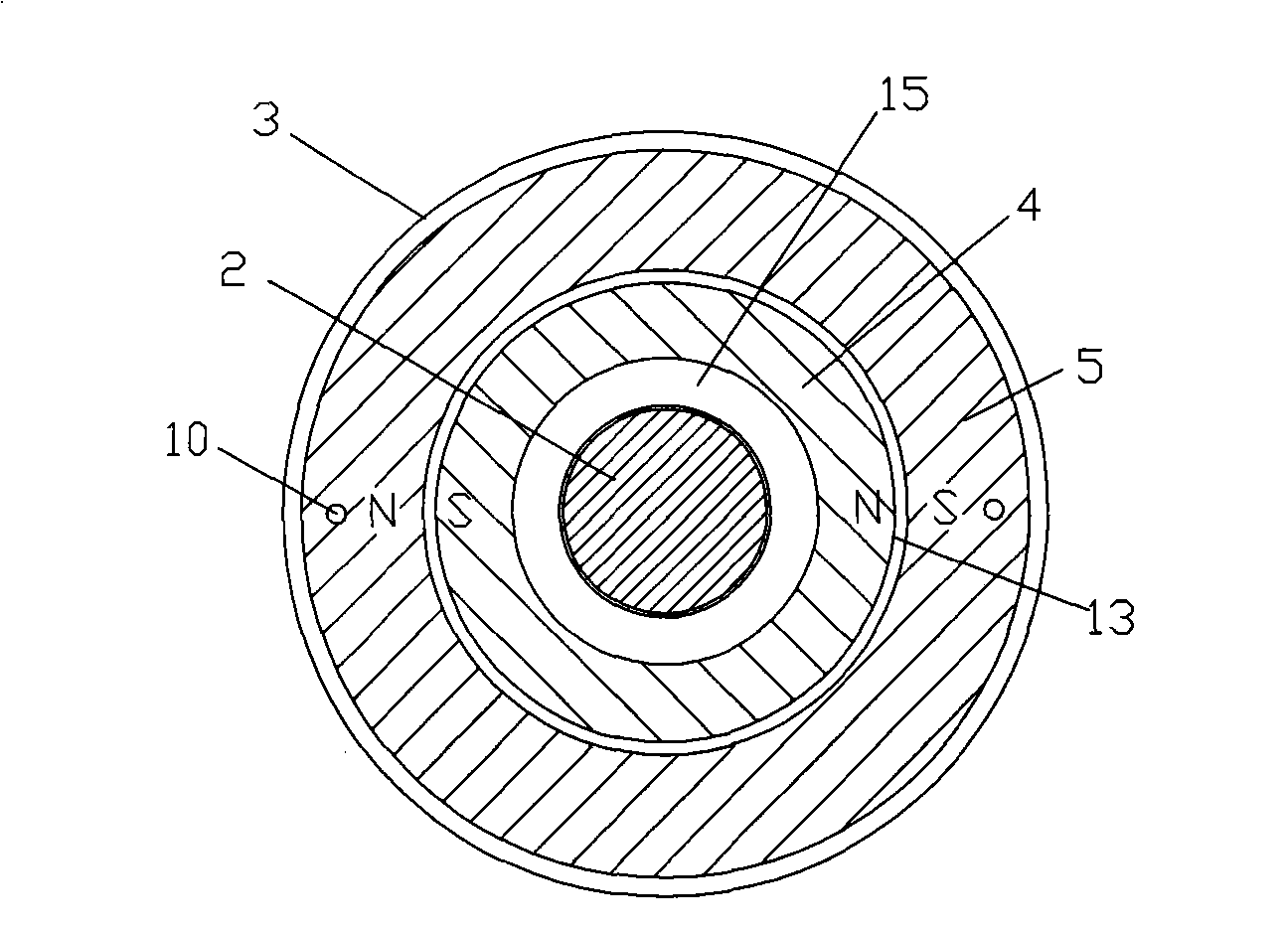

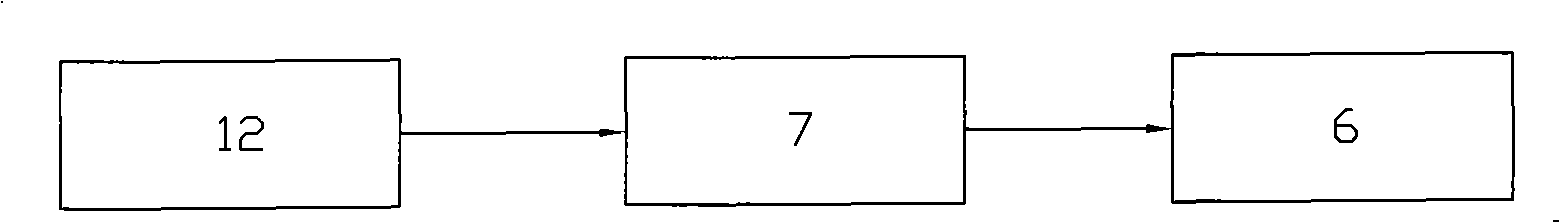

[0029] see figure 1 , figure 2 , the controllable permanent magnet maglev damping spring with an air damping chamber of the present invention includes a base 1, a support shaft 2, a casing 3, a mover 4, a stator 5, a stator excitation winding 6, and an electromagnetic controller 7;

[0030] The base 1 has a cylindrical structure, and a cavity is opened in the center as a damping air cavity 100, and an air inlet 101 is opened at the bottom, and a sealing sheet 8 is fixed and sealed with a fixing screw 9; a support shaft 2, whose outer diameter is the same as that of the base 1 The inner diameter of the damping air cavity 100 matches, one end of which is inserted into the base damping air cavity 100, and the end is provided with a sealing ring 16;

[0031] The casing 3 is fixed on the base 1 and includes a bottom plate 31, a casing 32 and an end cover 33; a through hole is opened in the center of the bottom plate 31 and the end cover 33, and bearings 15 and 15' are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com