Novel three-barrel structure quick-fixing water tube boiler

A water-tube boiler and drum technology, applied in water-tube steam boilers, steam boilers, water heaters, etc., can solve the problems of high power consumption, large air leakage coefficient, large steel consumption, etc., and achieve high thermal efficiency and low workload. , the effect of small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

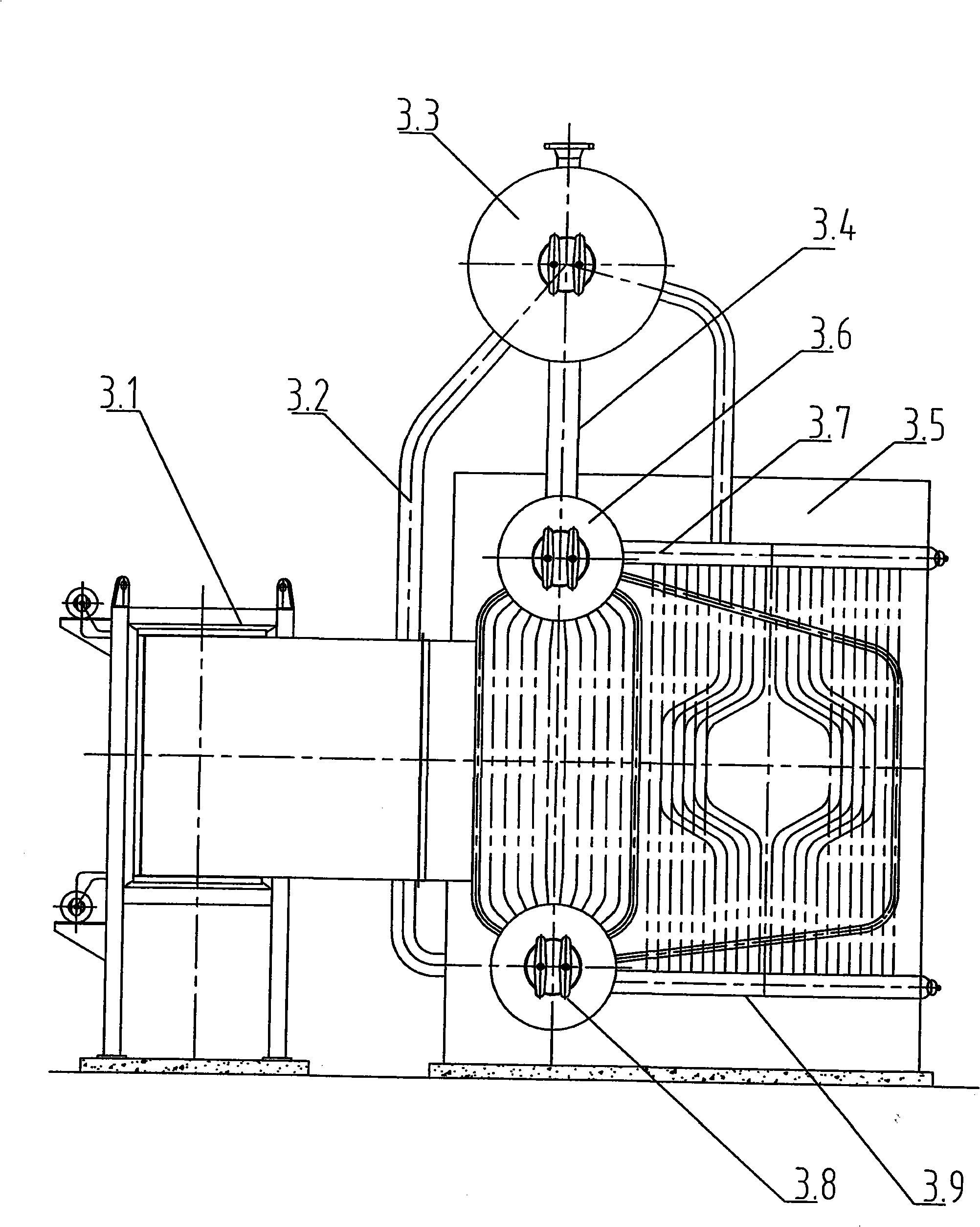

[0027] see image 3 ~ 4. The new three-drum structure fast-installed water tube boiler involved in the present invention adopts a three-drum vertical "D" layout structure as a whole. It is mainly composed of economizer 3.1, downcomer 3.2, overhead drum 3.3, riser 3.4 and boiler body 3.5.

[0028] The overhead drum 3.3 is located above the boiler body 3.5, supported by the riser pipe 3.4, and the economizer 3.1 is located on the left side of the boiler body 3.5,

[0029] The boiler body 3.5 includes an intermediate drum 3.6, a lower drum 3.8, a convection tube bundle 3.10, a superheater 3.16, a furnace 3.11, an upper header 3.7 and a lower header 3.9, and the intermediate drum 3.6 and the lower drum 3.8 are arranged up and down , the convection tube bundle 3.10 is connected between the middle drum 3.6 and the lower drum 3.8, the middle drum 3.6 is supported by the convection tube bundle, and the weight of the middle drum is transferred to the lower drum by the convection tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com