MEMS design optimizing method

An optimization method and a technology for optimizing variables, applied in computing, special data processing applications, instruments, etc., can solve problems such as inability to apply multiple optimization algorithms and long optimization process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

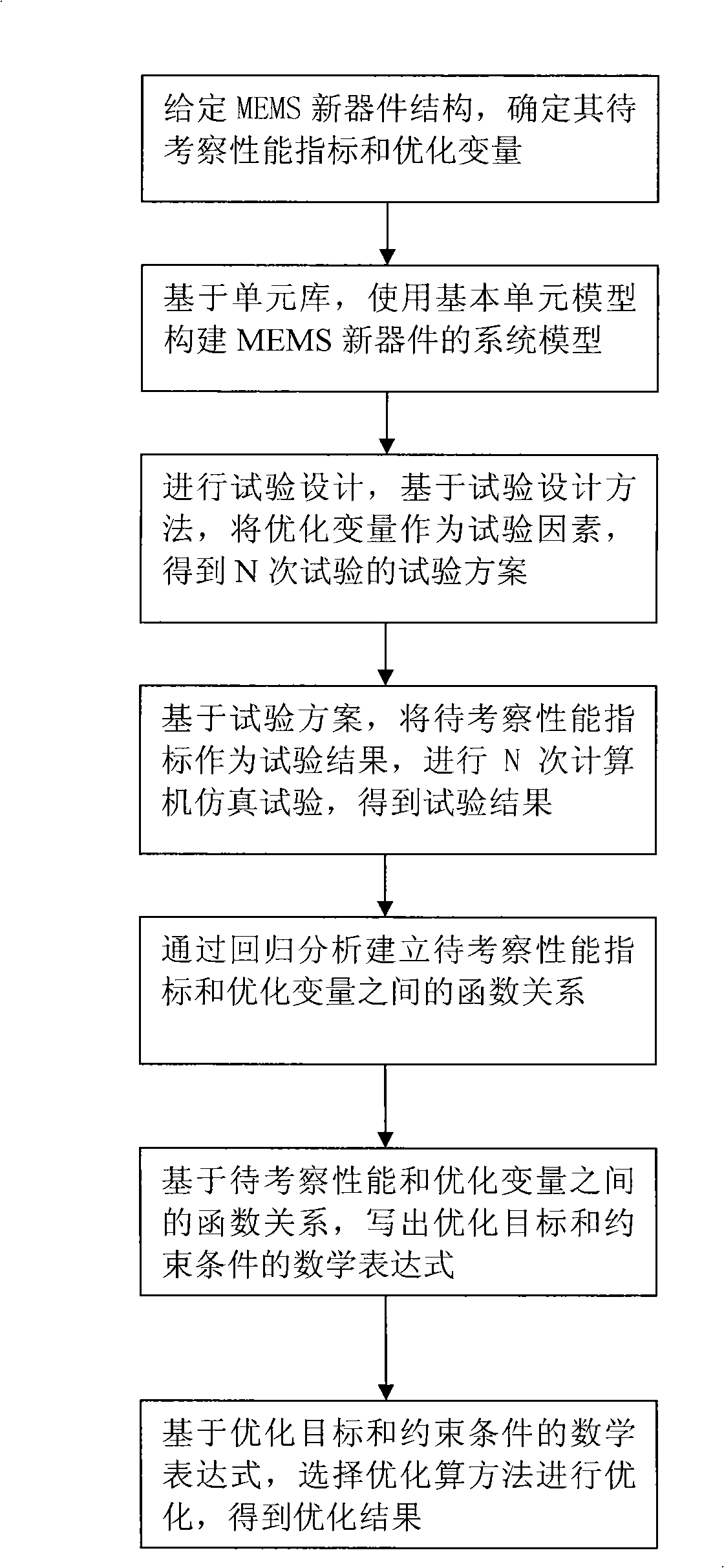

[0046] A design optimization method for a MEMS micro-gyroscope, comprising the following steps:

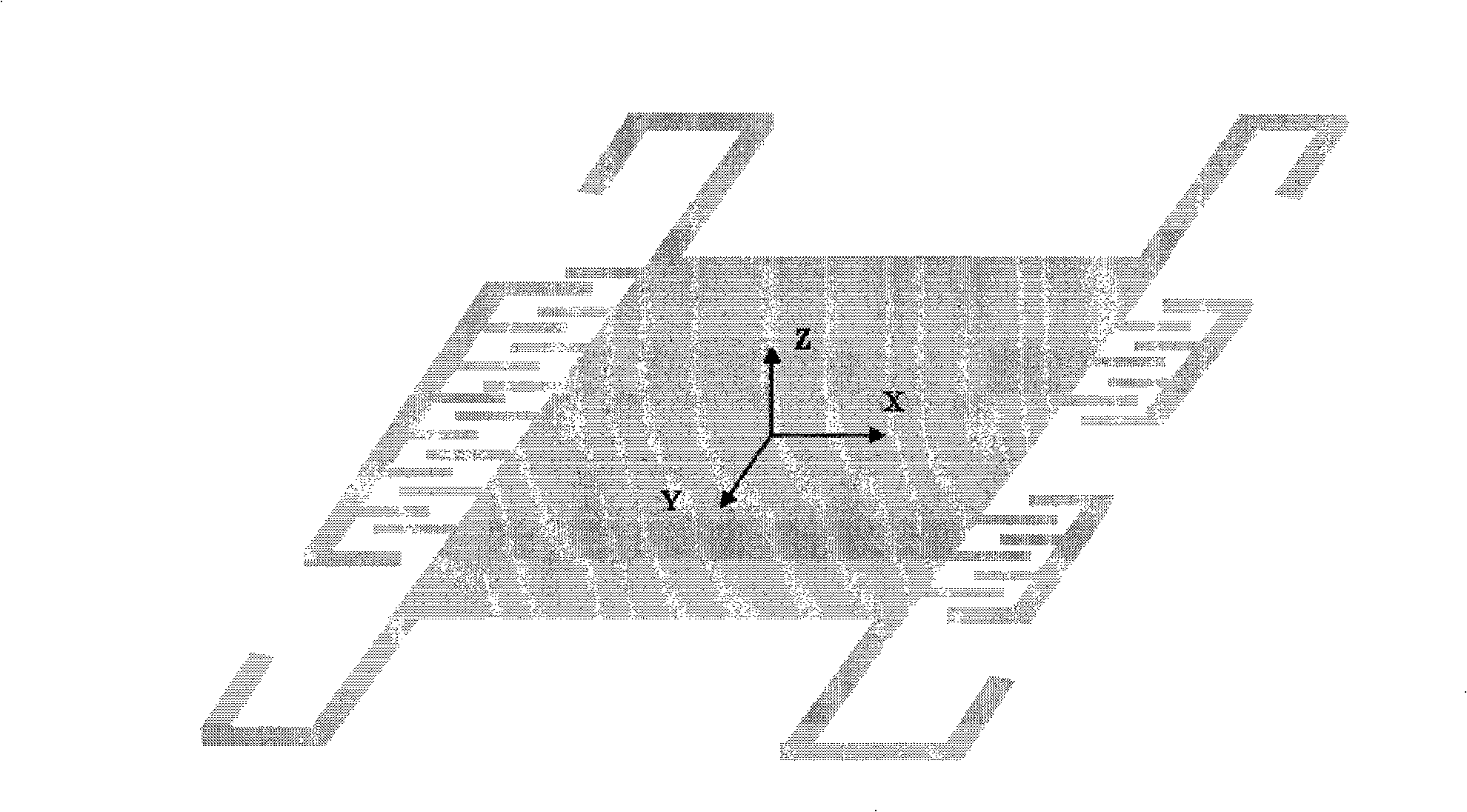

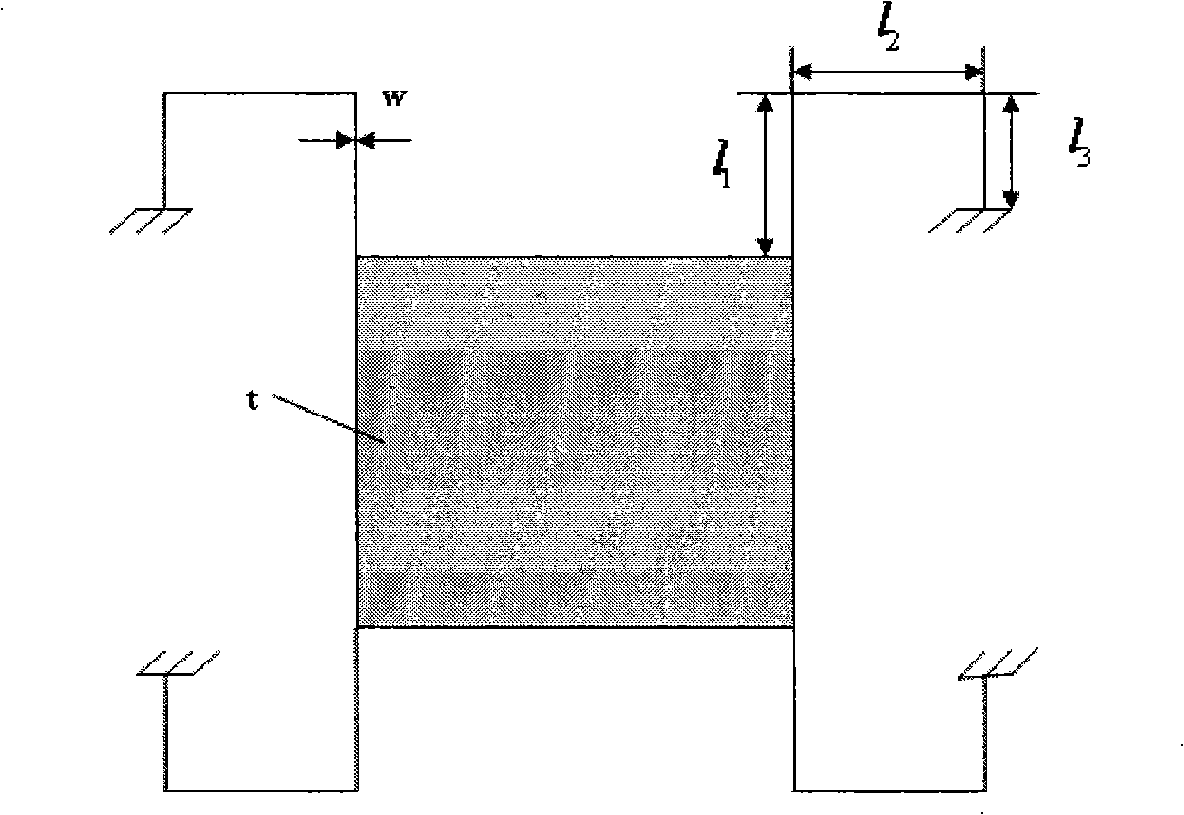

[0047] 1. Given the MEMS device structure, determine its performance index y to be investigated m (m=1, 2, ...M) and optimization variable x i (i=1, 2, . . . n). In this embodiment, the MEMS micro-gyroscope is used as the design optimization object. Schematic diagram of the structure of the MEMS micro-gyroscope, see figure 2 . The performance index to be investigated is the resonant frequency fx of the drive mode and the resonant frequency fy of the detection mode. The optimization variables are thickness t, beam width w, beam 1 length l 1 , beam 2 length l 2 , beam 3 length l 3 . For a diagram of optimization variables, see image 3 . Optimize variable value range see Figure 4 .

[0048] 2. Based on the cell library, use the basic cell model to construct the system model of the MEMS device. This embodiment is based on the ARCHITECT unit library, using the basic uni...

Embodiment 2

[0064] A design optimization method for a MEMS microresonator, comprising the following steps:

[0065] 1. Given the MEMS device structure, determine its performance index y to be investigated m (m=1, 2, ...M) and optimization variable x i (i=1, 2, . . . n). In this embodiment, the MEMS micro-resonator is used as the design optimization object. Schematic diagram of the structure of the MEMS microresonator see Figure 10 . The performance index to be investigated is to make the resonant frequency fy in the y direction. The optimization variables are horizontal beam length lb, horizontal beam width wb, vertical beam length lt, vertical beam width wt, mass length lsy connected to the electrostatic comb, mass width wsy connected to the electrostatic comb, and middle mass width wsa . For a diagram of optimization variables, see Figure 11 . Optimize variable value range see Figure 12 .

[0066] 2. Based on the cell library, use the basic cell model to construct the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com