High-resolution Forbes aspherical photoetching objective lens

A high-resolution, aspheric surface technology, applied in the field of high-resolution projection lithography objective lens, can solve the problems of high tolerance sensitivity, large number of aspheric surfaces, etc., achieve the effect of reducing assembly time, simple structure of objective lens, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

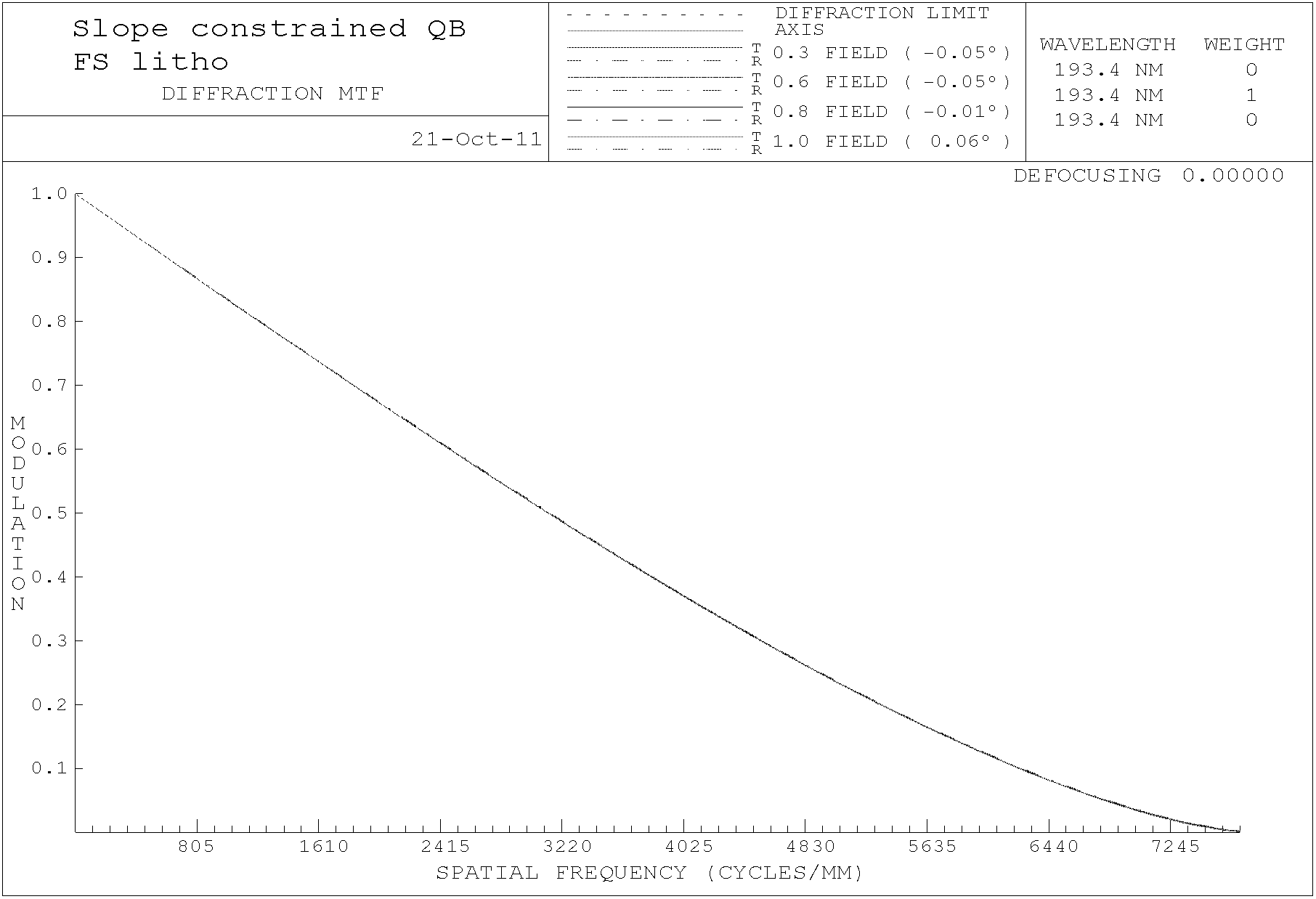

[0030] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

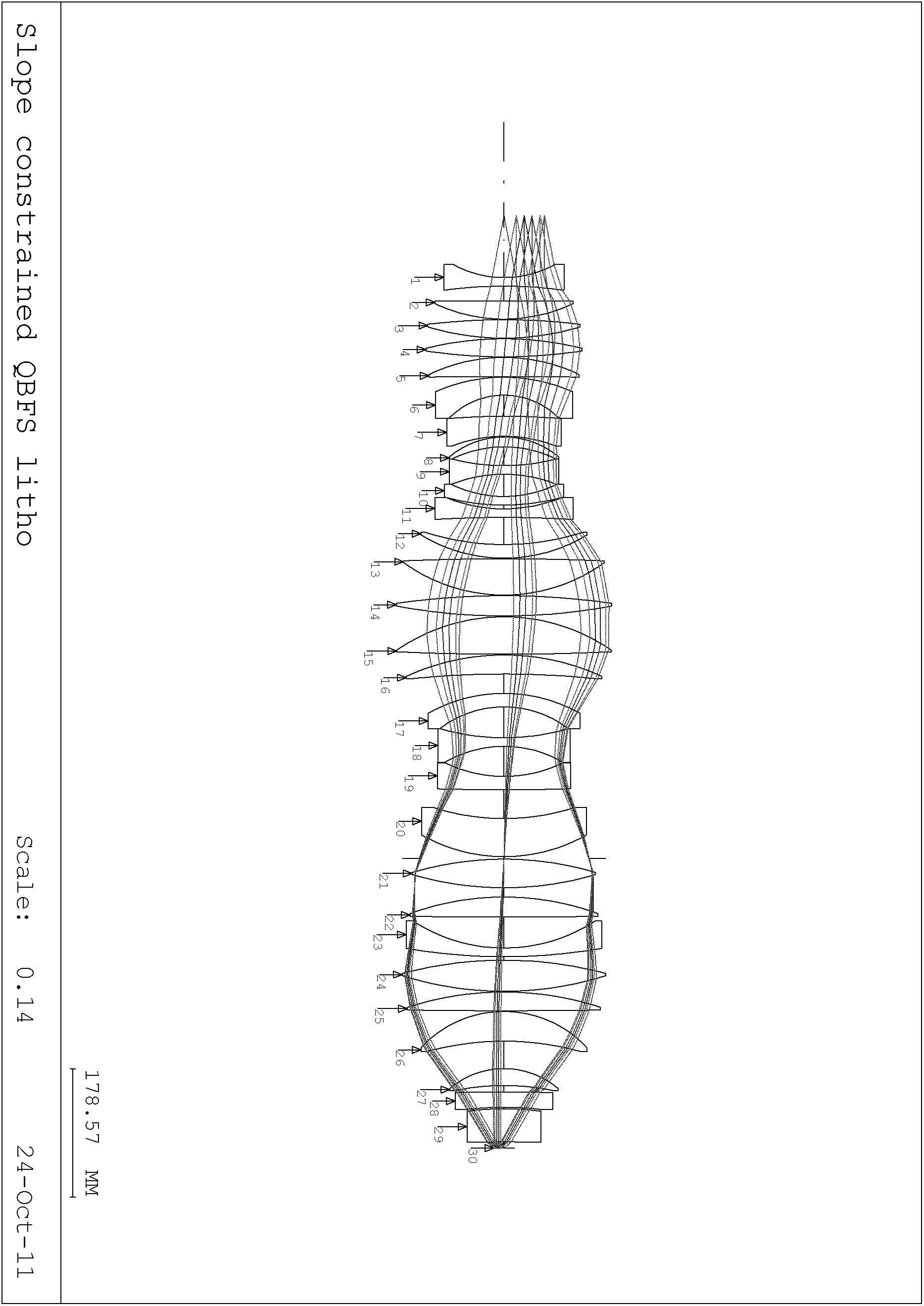

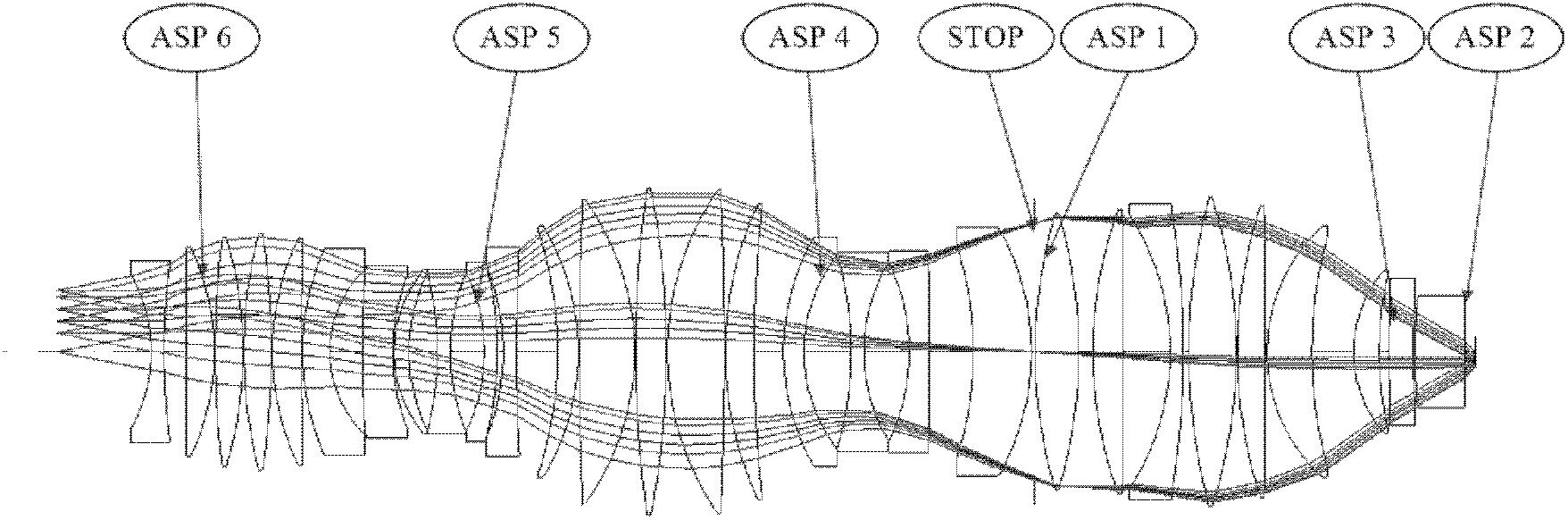

[0031] The high-resolution Forbes aspheric lithography objective lens in this example is composed of front and rear lens groups, and a total of 29 lenses are used, including 6 Forbes aspheric surfaces. Such as figure 1 As shown, lenses 1 to 20 are the front lens group, lenses 21 to 29 are the rear lens group, and the image plane 30 is the surface where the silicon chip is located. The lens material uses fused silica (refractive index of 1.560326 at the system center wavelength of 193.368nm) as the main lens material, and calcium fluoride (refractive index of 1.501455 at the system center wavelength) as the material used to correct chromatic aberration.

[0032] The front lens group includes a first negative lens 1, a first positive lens 2, a second positive lens 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com