Wheel bearing with sensor

A sensor and sensor unit technology, applied in the field of wheel bearings, can solve the problems of high cost and poor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

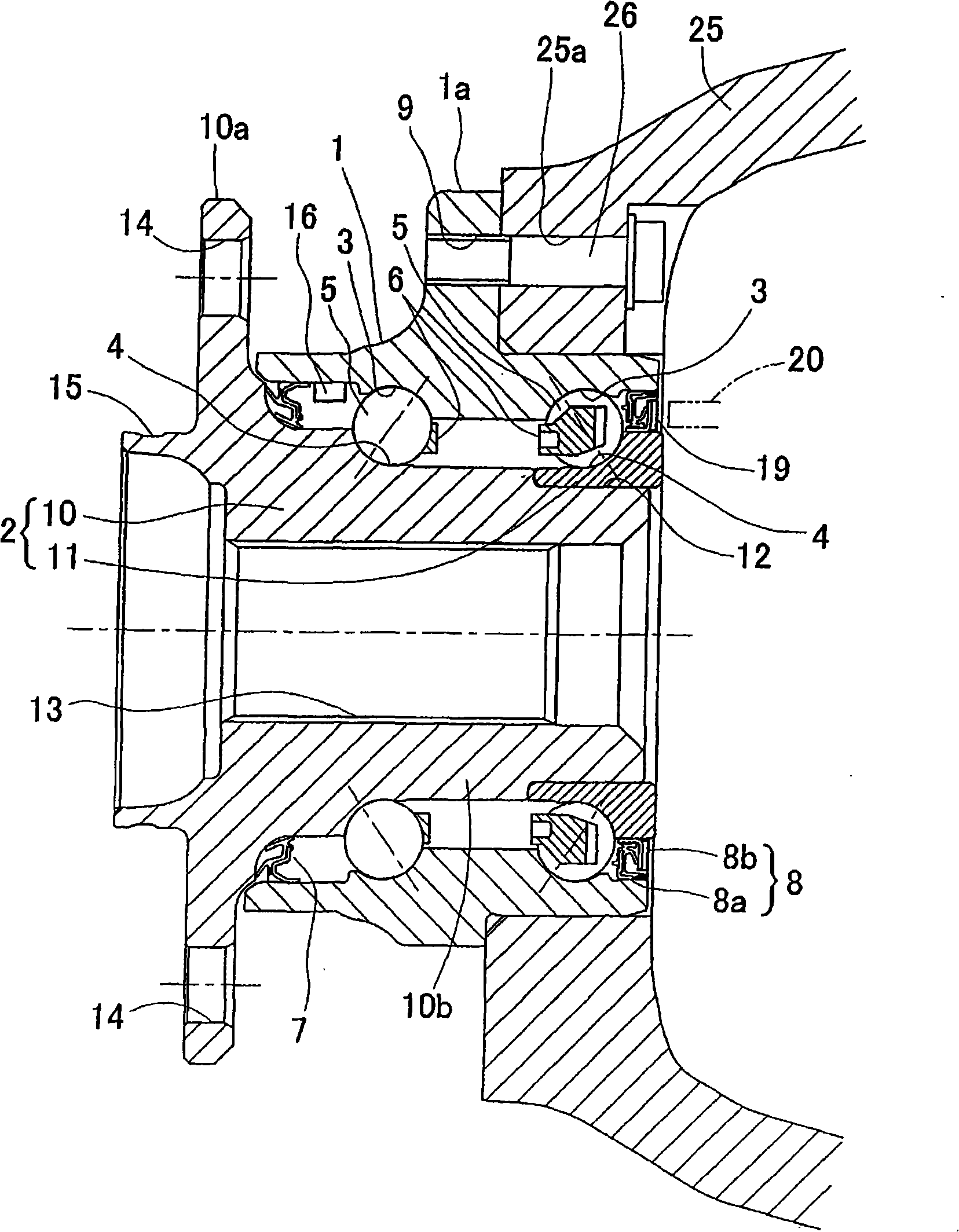

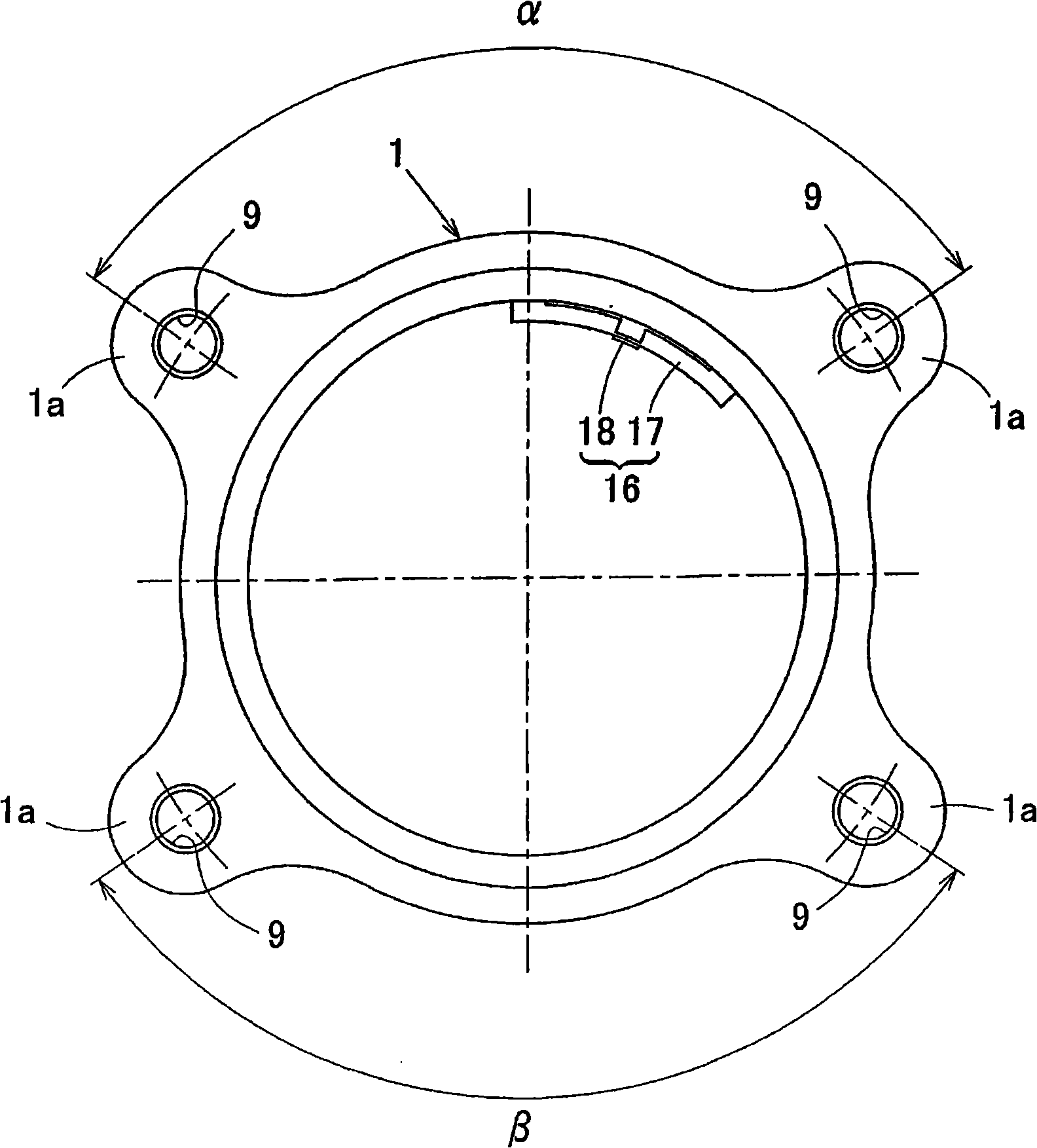

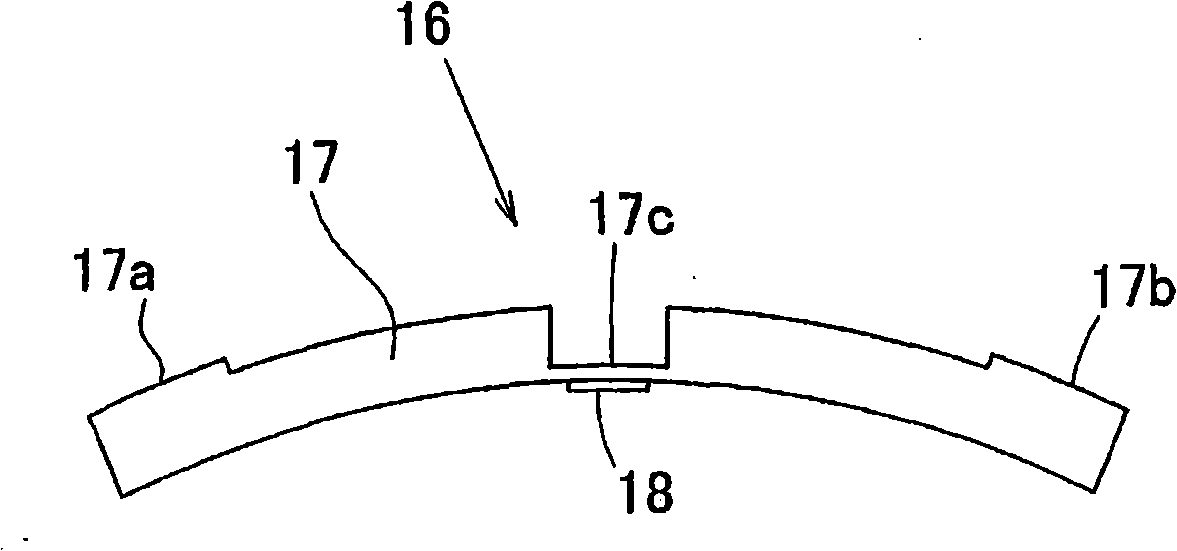

[0062] according to figure 1 ~ Fig. 3 illustrates the first embodiment of the present invention. This embodiment is a third-generation inner ring rotation type, and is suitable for a wheel bearing for supporting a driving wheel. In this specification, when mounted on a vehicle, the side toward the outside in the vehicle width direction of the vehicle is referred to as the outer side, and the side toward the center of the vehicle is referred to as the inner side.

[0063] The wheel bearing comprises: an outer member 1 formed with a plurality of rows of rolling surfaces 3 on the inner periphery; an inner member 2 formed with rolling surfaces 4 facing each of the rolling surfaces 3; sandwiched between these outer members 1 and Multiple rows of rolling elements 5 between the rolling surfaces 3, 4 of the inner part 2. This wheel bearing is a multi-row angular contact ball bearing type, the rolling elements 5 are made of balls, and each row is held by a cage. The rolling surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com