Drawing and processing apparatus

A technology for deep processing and tools, which is applied in the field of deep drawing processing equipment, can solve the problems of increased installation space, slow processing speed, and increased cost, and achieve the effects of correct and simple rotation control, shortened cycle time, and suppressed costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

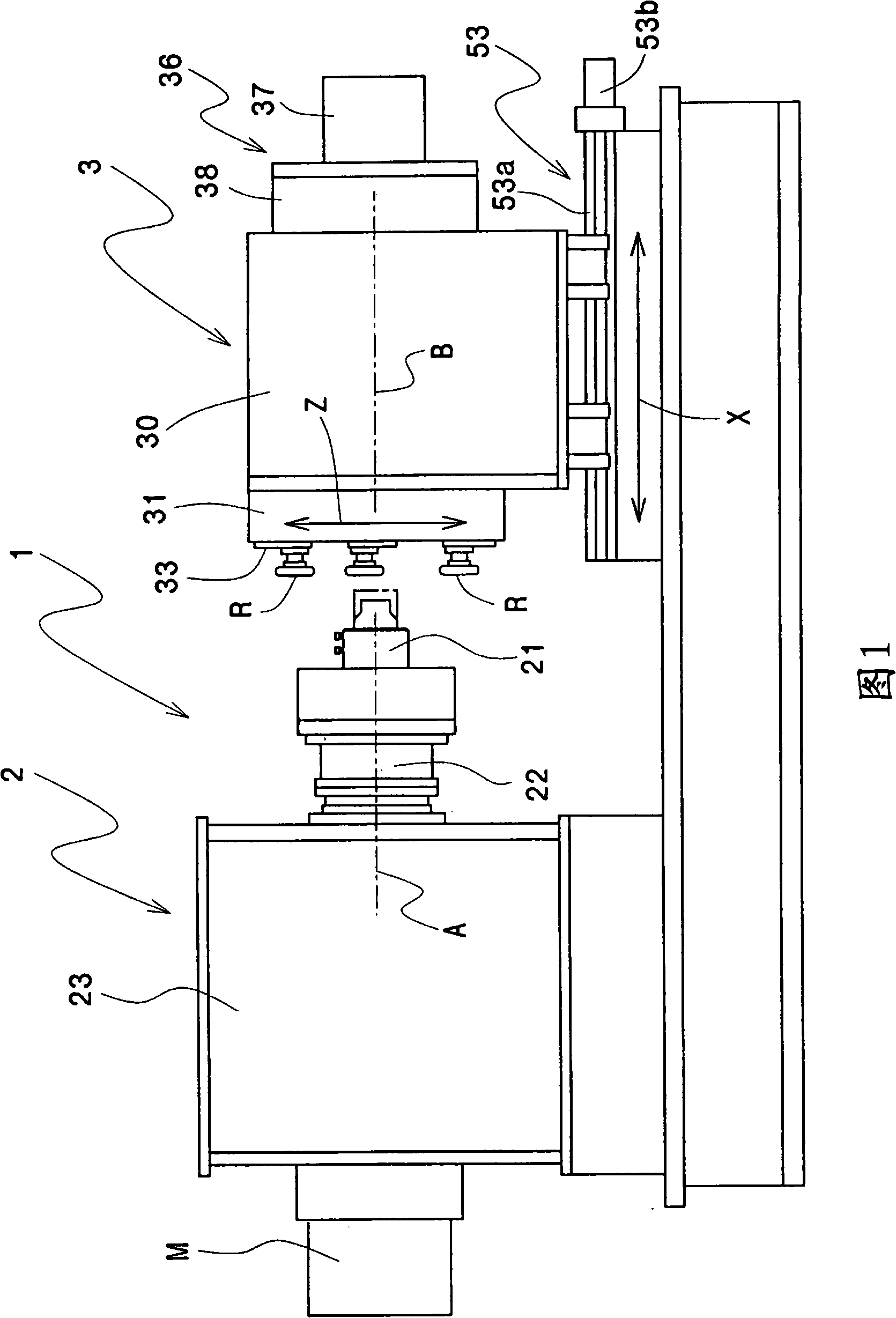

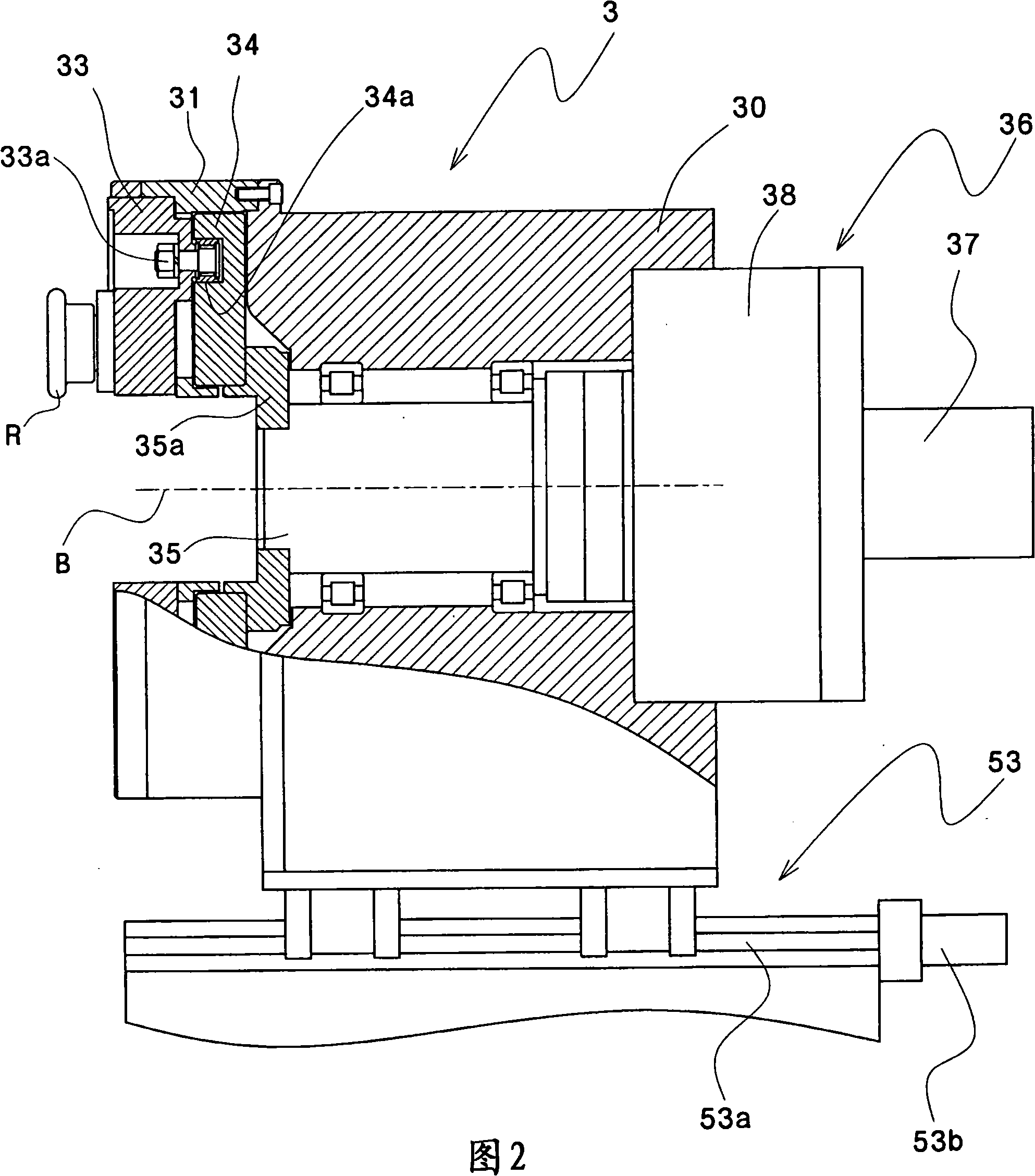

[0034] Figure 1~ Figure 4 An example of the drawing processing device of the present invention is shown.

[0035] This drawing machine 1 has a spindle mechanism 2 and a tool mounting mechanism 3 to which a squeeze roll R provided facing the spindle mechanism 2 is mounted, as in the prior art example.

[0036] The front end of the spindle mechanism 2 is equipped with a holding mechanism 21, which is used to hold and fix the cylindrical workpiece W, and is installed so that the axis center of the workpiece W coincides with the axis A of the spindle mechanism 2. .

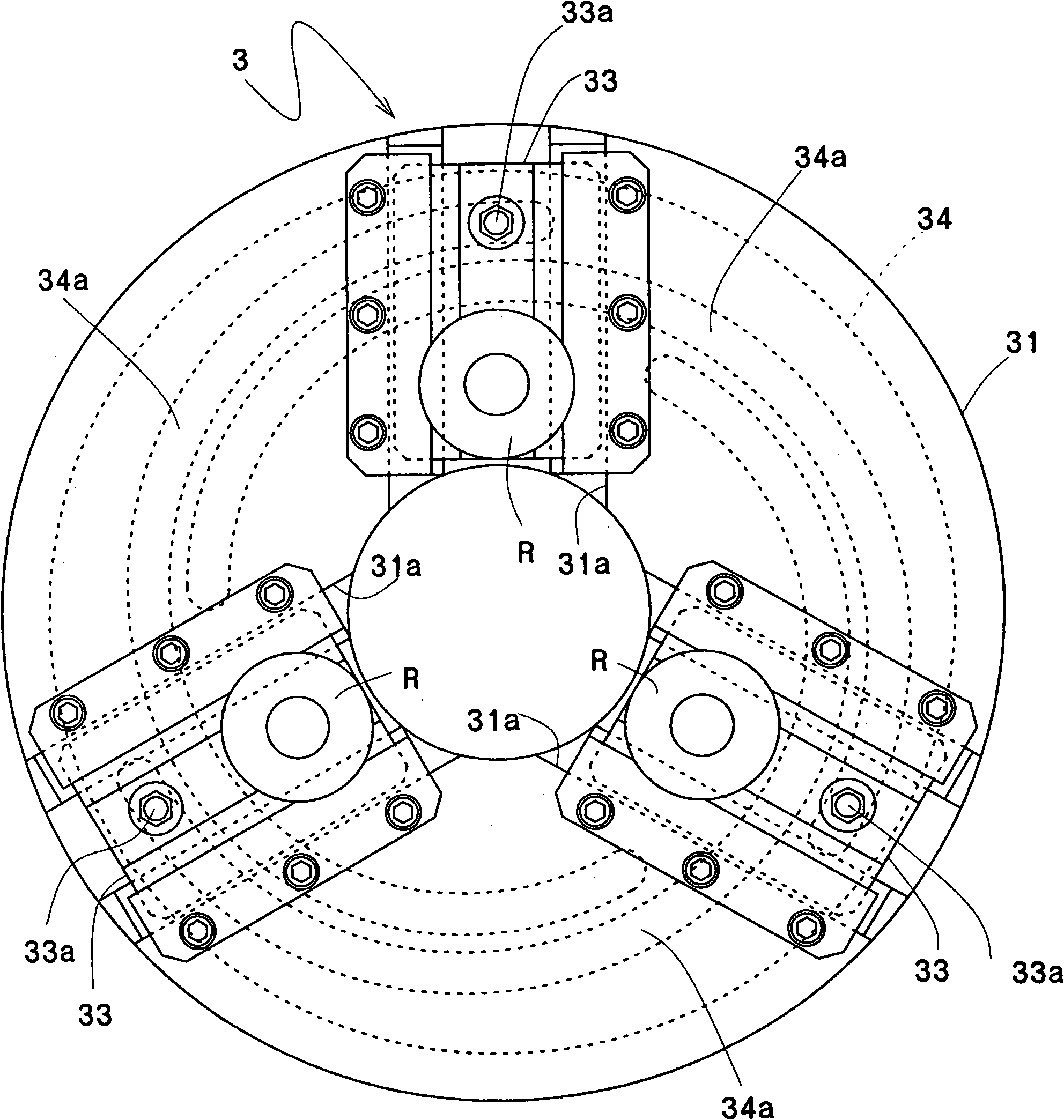

[0037] Furthermore, the tool mounting mechanism 3 is composed of a cylindrical main body 30, a panel 31 arranged on a side surface of the main body 30, and a plurality of parts arranged on the panel 31 so as to be movable in a direction perpendicular to the axis A of the main shaft 22. A roller mounting table 33, a cam plate 34 engraved with a helical groove 34a for fitting a guide pin 33a protruding from the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com