Stapler

A stapler and staple technology, which is applied to manufacturing tools, staple staple tools, etc., can solve problems such as small displacement, and achieve the effect of fewer manufacturing processes and stable binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

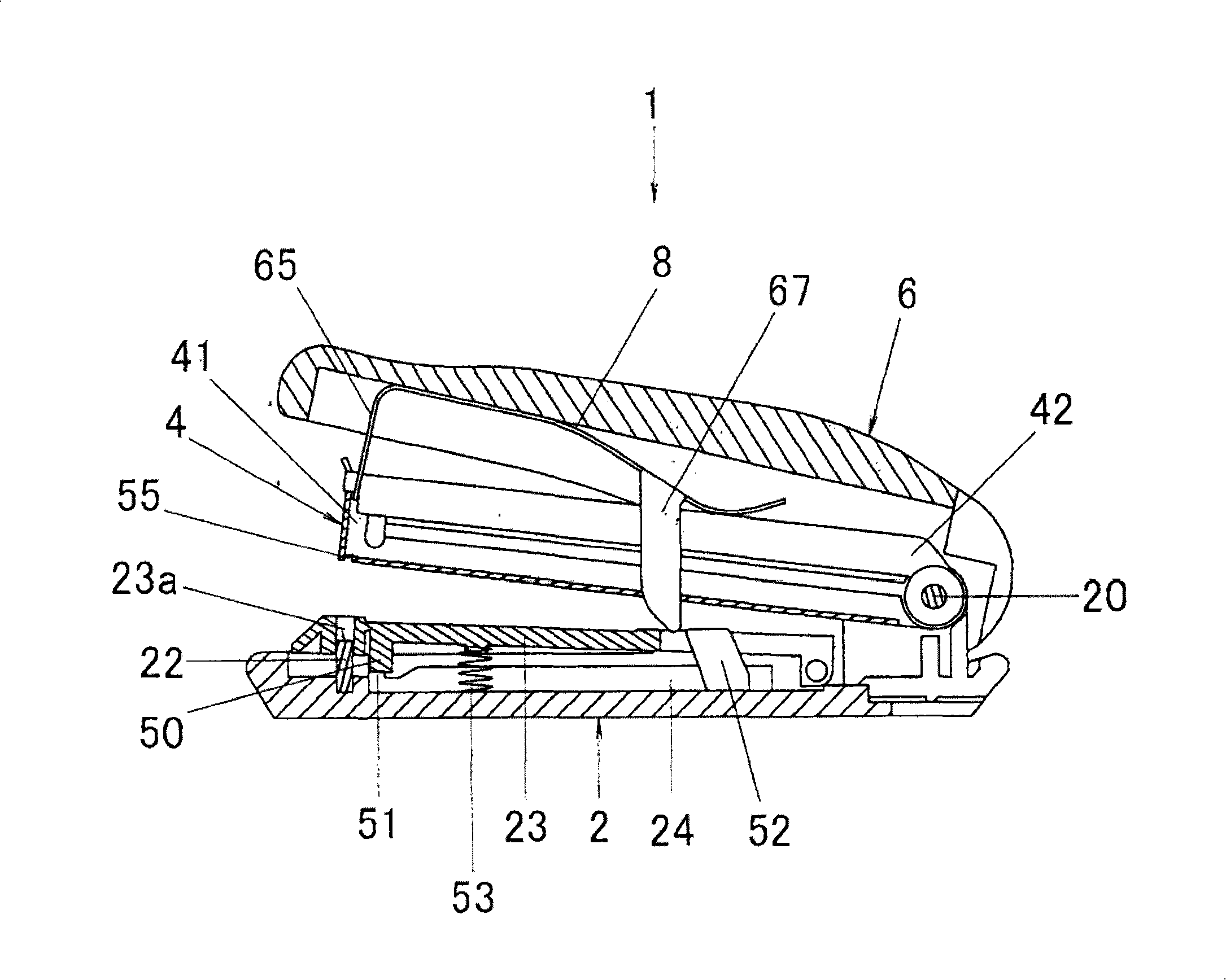

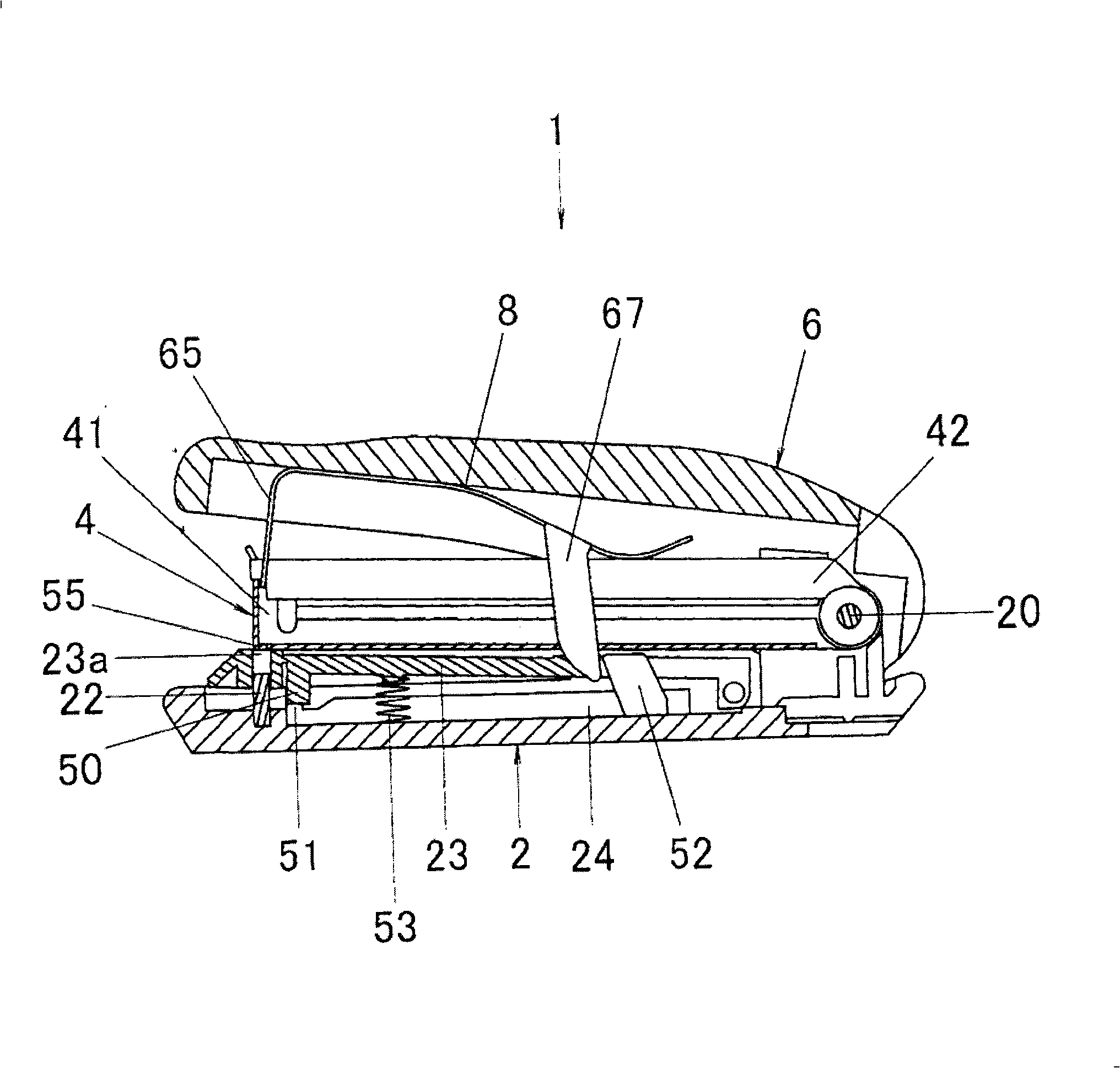

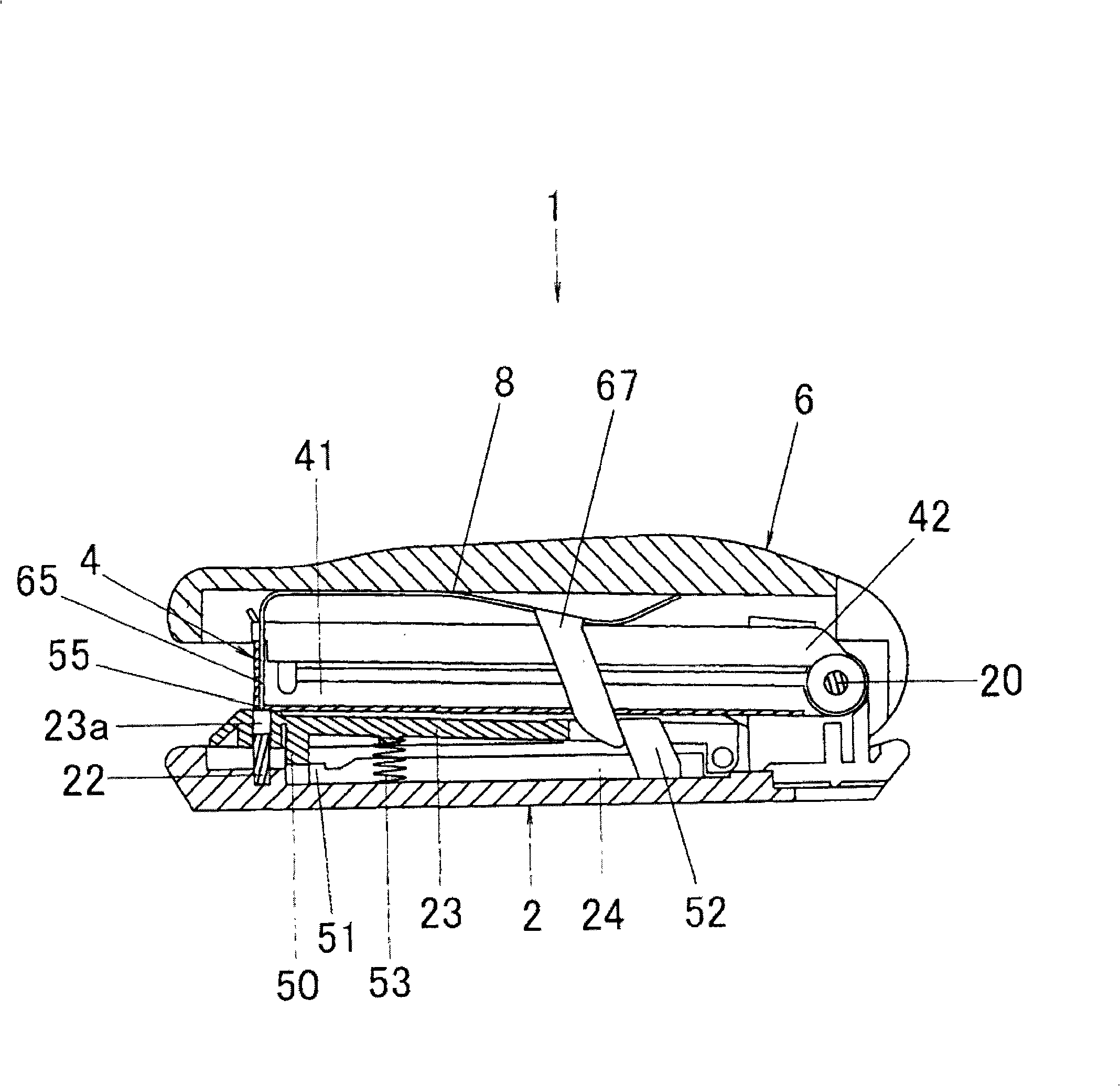

[0031] In order to realize the stapler 1 of the best form of the present invention, a kind of handle part 6 that has pressing knife 65 at the front part can rotate at a fixed axis with respect to the base part 2 via the main shaft 20, and the inner side of the handle part 6 The stapler 1 is a stapler 1 in which the staple cartridge unit 4 is also rotatable at a fixed axis toward the base unit 2 through the main shaft 20 . The base part 2 is equipped with a machine platform 23 biased upwards, and is provided with a sliding plate 24 that allows the machine platform 23 to perform a downward movement and slide backward, and has a sliding support claw 52 for the sliding plate 24. On the one hand, a concave platform 22 is provided on the abutment part 2, and a leaf spring 8 is assembled on the handle part 6, and a slide plate holding part 67 is provided on the side of the leaf spring 8 in a form that can protrude downward, so that it can slide The slider pressing portion 67 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com