Thermal sensitive printer head and method for producing the same

A thermal printing head and manufacturing method technology, applied in printing and other directions, can solve the problems of uneven temperature distribution curve of heating body, affecting the clarity of printed text and graphics, and irregular shape of pixel points, so as to reduce tailing phenomenon, Good thermal conductivity, shape-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

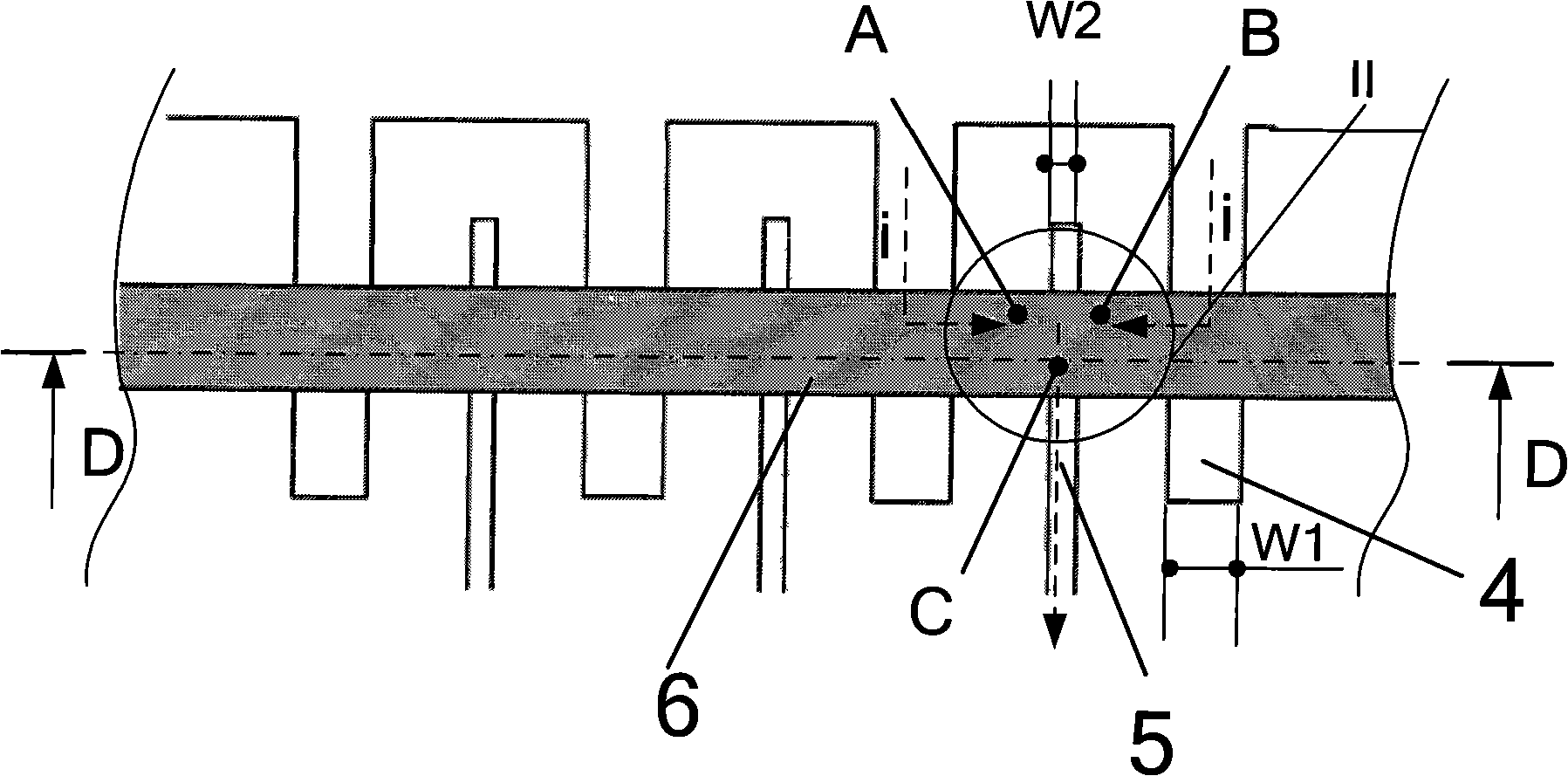

[0020] Below in conjunction with accompanying drawing, the present invention is further described.

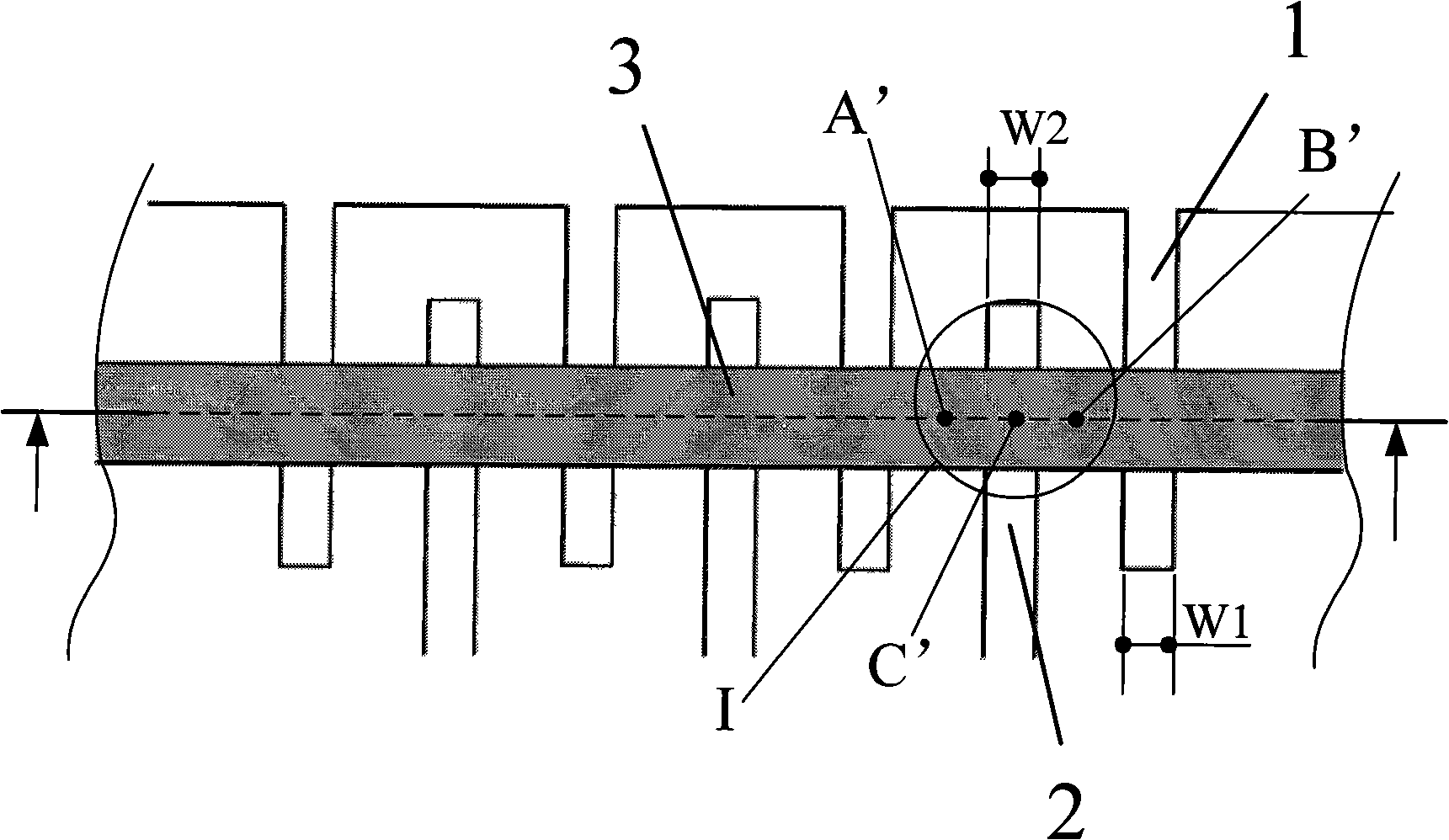

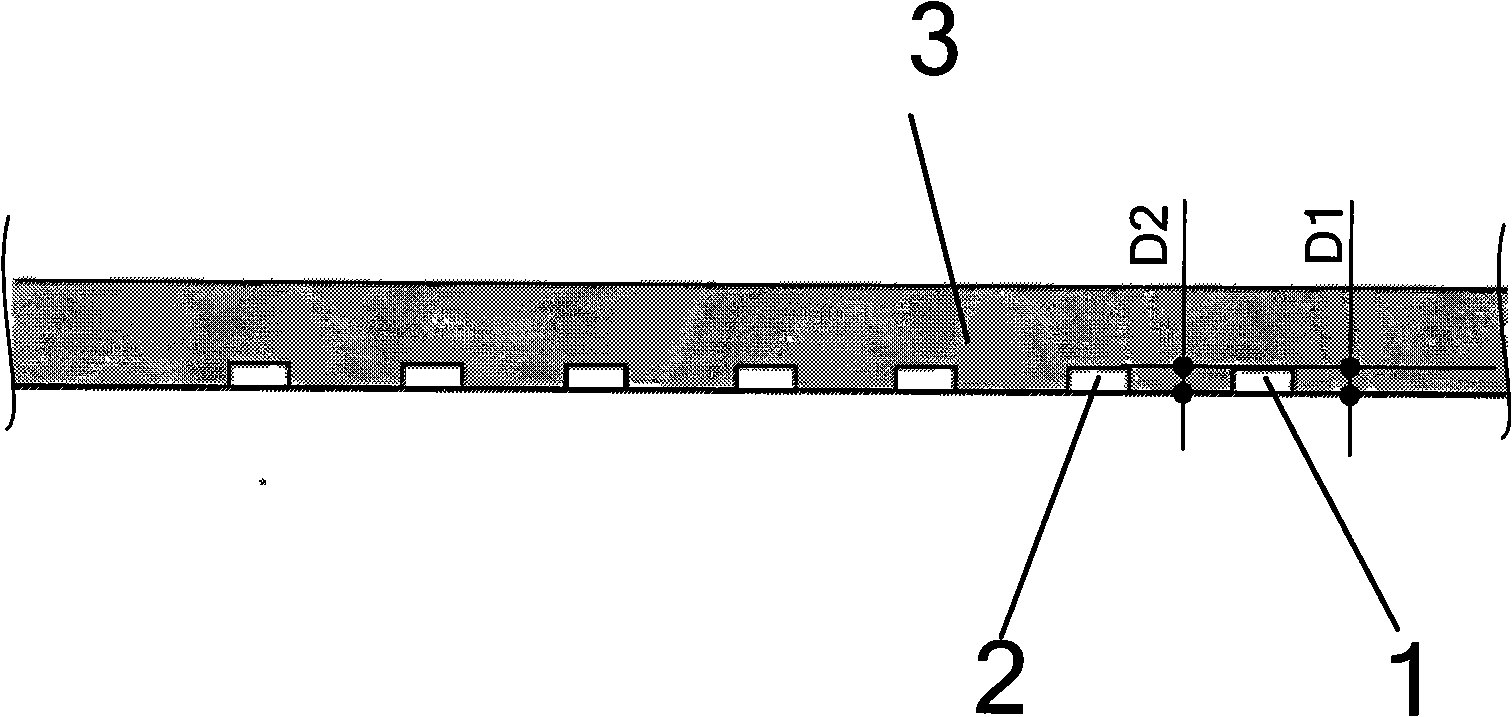

[0021] image 3 It is a schematic diagram of the local structure of the printing head of the present invention. Figure 4 yes image 3 A-A sectional view is shown. Combine below image 3 , Figure 4 The structure of the print head of the present invention will be described. Such as image 3 As shown, the structure of the print head of the present invention includes: a common electrode 4 , individual electrodes 5 , and a heating element 6 .

[0022] The common electrode 4 is connected to a power supply to provide energy for the heating element 6 when the print head is working. The width W1 of the common electrode 4 is: 25μm<W1≤50μm, the thickness D1 is 0.2μm<D1≤2.0μm, and the material of the common electrode 4 is metal gold, which has excellent electrical conductivity, thermal conductivity and chemical stability. Ideal material for head electrodes.

[0023] The individu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com