Controllable clutch transfer case for four-wheel drive vehicle

A four-wheel drive, transfer case technology, applied in the field of transfer case, can solve the problems of slow response speed and poor passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes embodiments of the present invention based on the drawings.

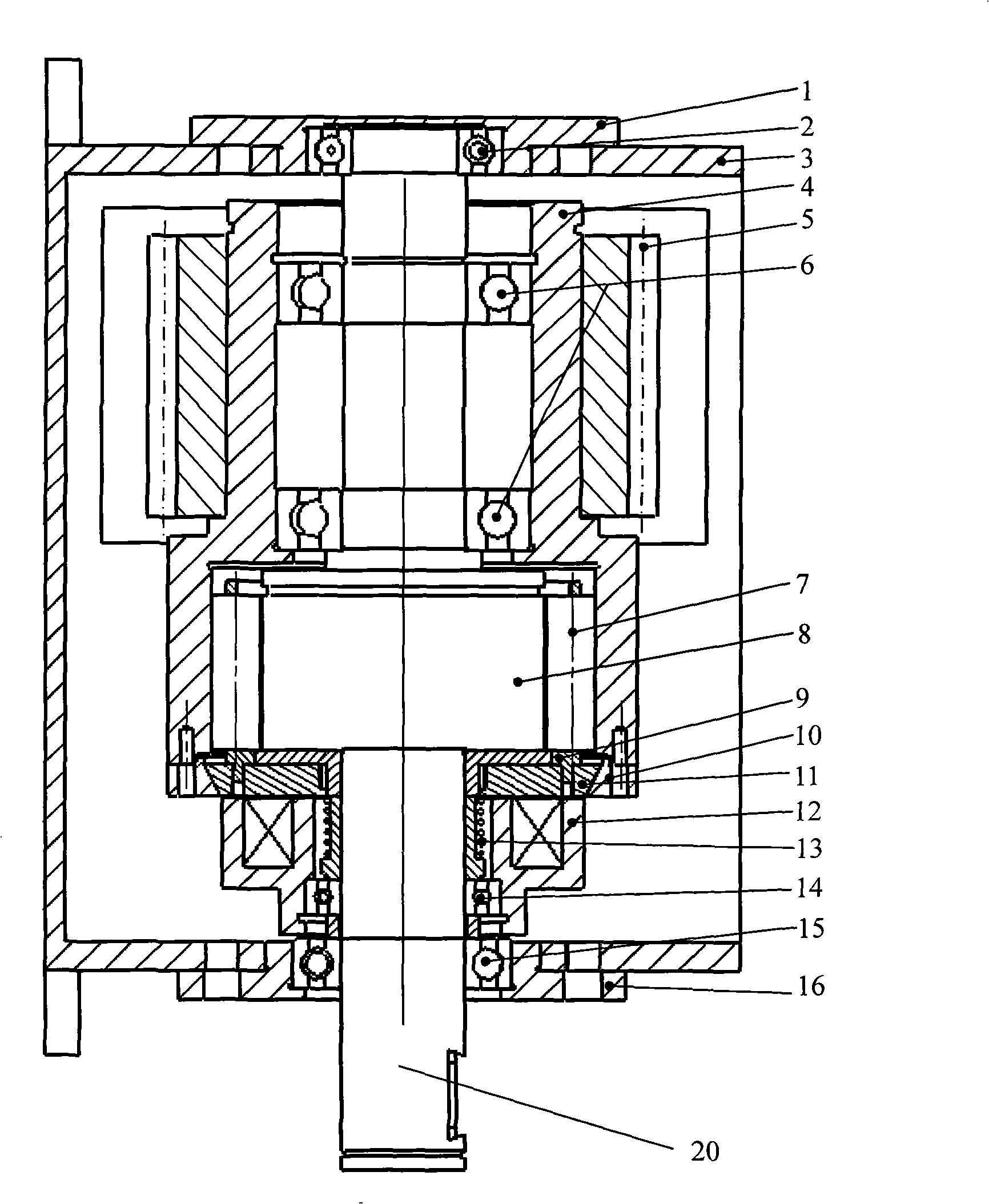

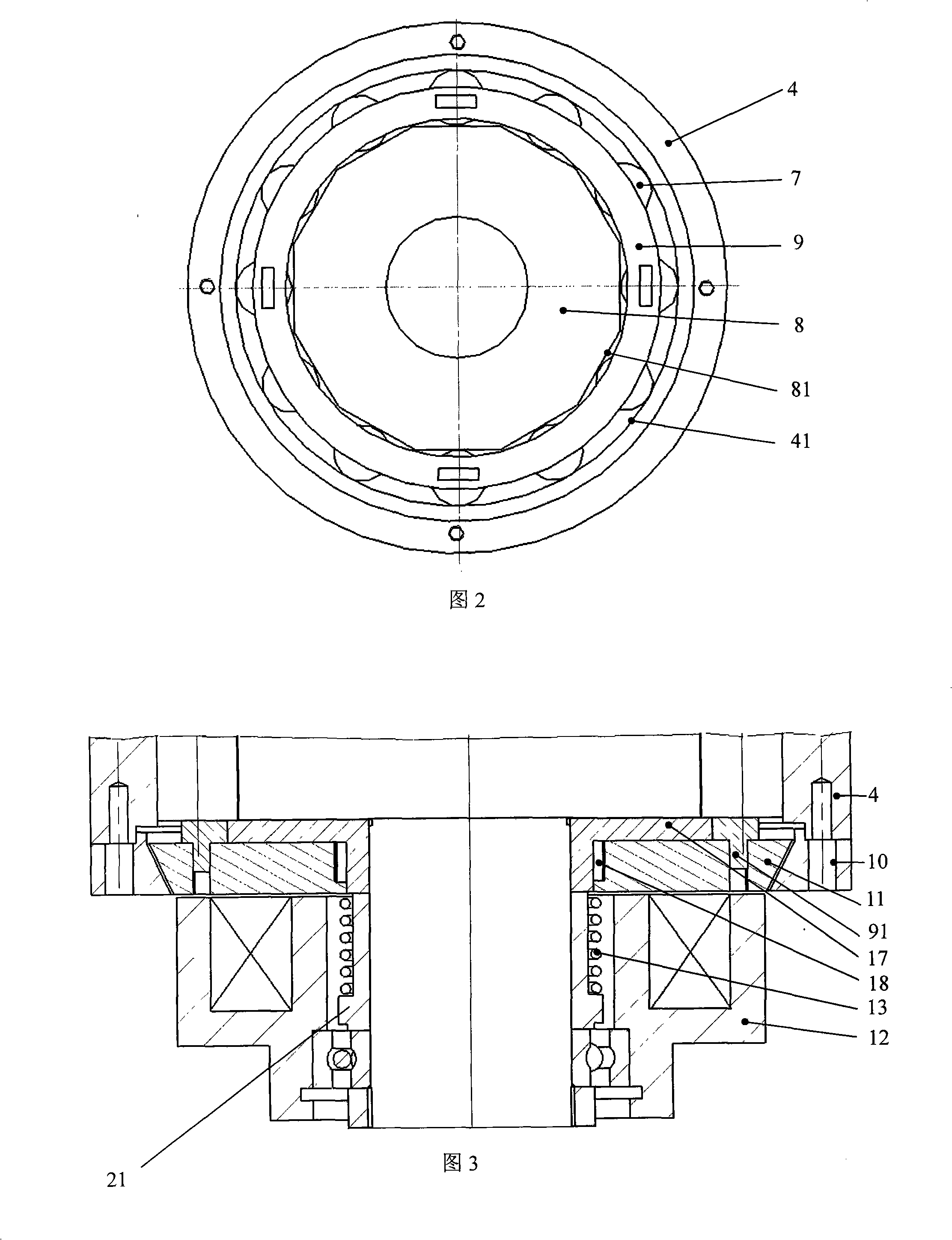

[0025] figure 1 ~ Figure 3 is an illustration of an embodiment of the present invention. figure 1 It is a cross-sectional view of the assembly. Figure 2 depicts the assembly diagram of the inner shaft, outer sleeve and cylindrical roller of the key transmission components. Figure 3 is an embodiment that uses an electric drive to control the clutch of the transfer case.

[0026] Such as figure 1As shown, the inner shaft 8 is installed on the transfer case 3 through the bearing 2, the bearing 15 and the bearing seat 1 and the bearing seat 16, and the output of the inner shaft 8 is connected to the main reducer of the non-driving axle in the two-drive mode. The outer sleeve 4 is mounted on the inner shaft 8 through a bearing 6 to allow relative free movement of the outer sleeve 4 and the inner shaft 8. The sprocket as the driven wheel 5 is fixed to one end of the outer sleeve 4 by a key. Par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com