Method for excessive heating protection of petrol engine catalyst

A gasoline engine, overheating protection technology, applied in engine components, engine control, engine ignition, etc., can solve the problem of lowering, not considering catalyst conversion efficiency, etc., to reduce harmful gas content, prevent catalyst overheating phenomenon, and improve emission standards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following embodiments are used to illustrate the present invention in conjunction with the accompanying drawings, but are not intended to limit the scope of the present invention.

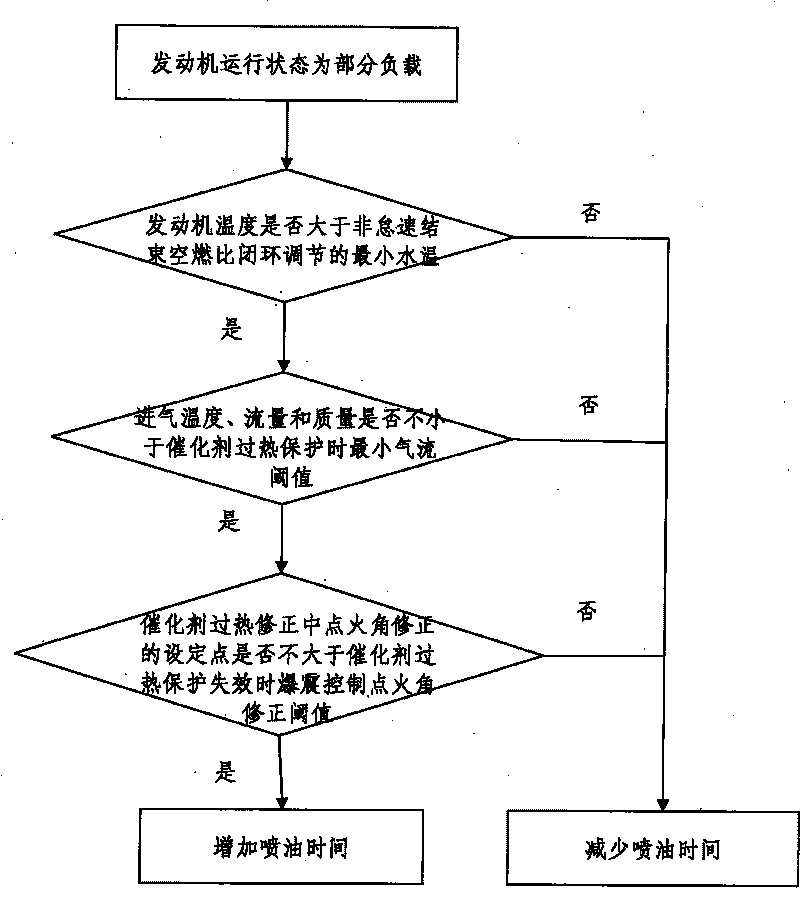

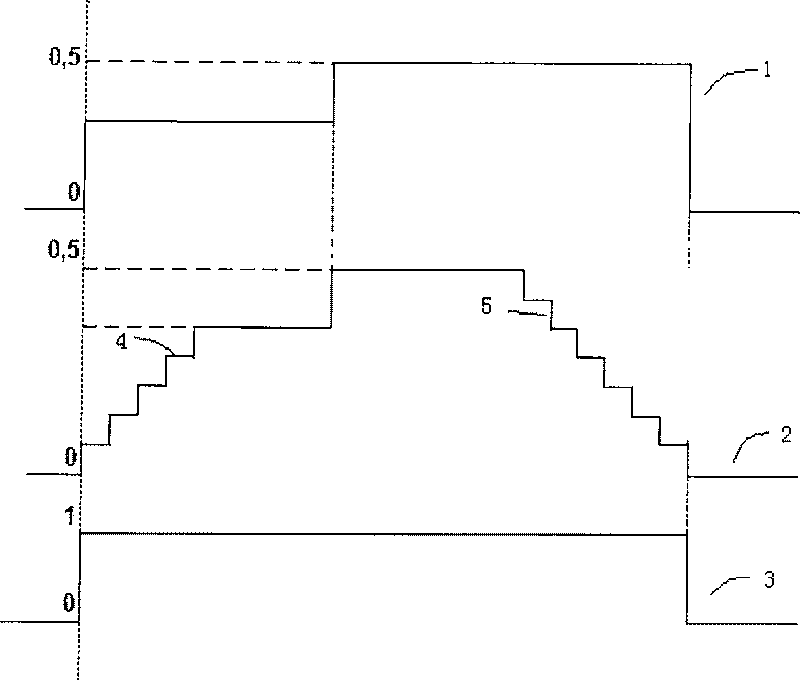

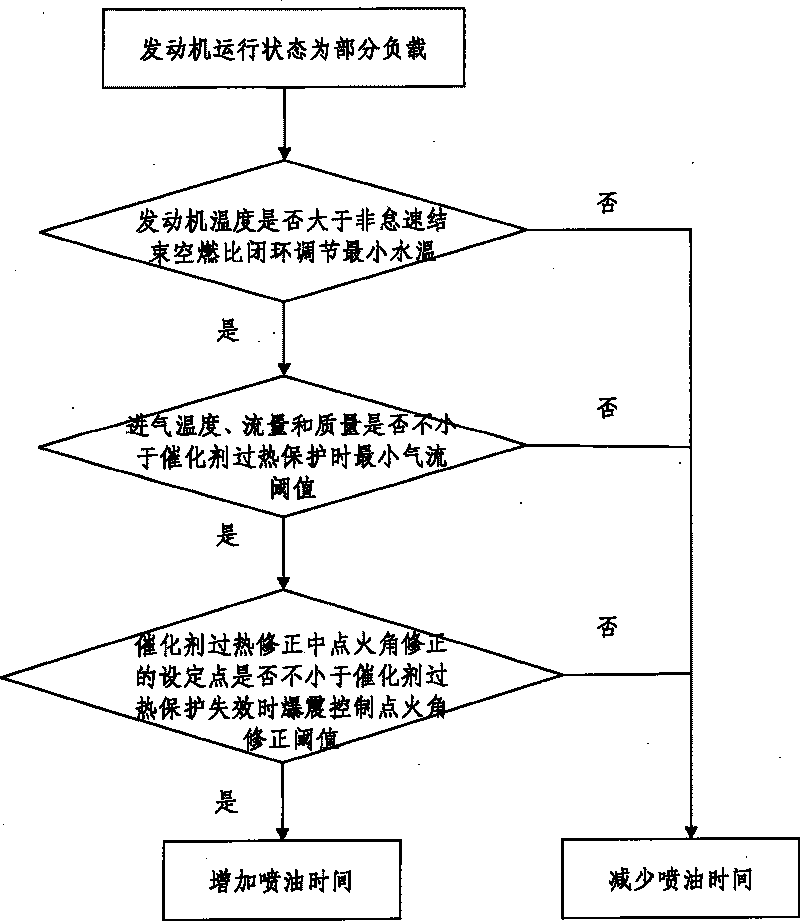

[0028] The principle of the gasoline engine catalyst overheating protection method provided by the present invention is as follows: first, the engine crankshaft speed signal is collected by the crankshaft position sensor, the throttle opening degree signal is collected by the throttle position sensor, the engine temperature signal is collected by the water temperature sensor, and the engine temperature signal is collected by the intake air sensor. The temperature sensor and the pressure sensor detect the temperature, flow and quality signals of the intake air, and detect the knock state of the engine through the knock sensor; secondly, the ECU (Electronic Control Unit, electronic control unit) collects the engine crankshaft speed signal and the throttle according to the crankshaft sensor. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap