Output measuring circuit and measuring method of capacitance differential pressure transducer

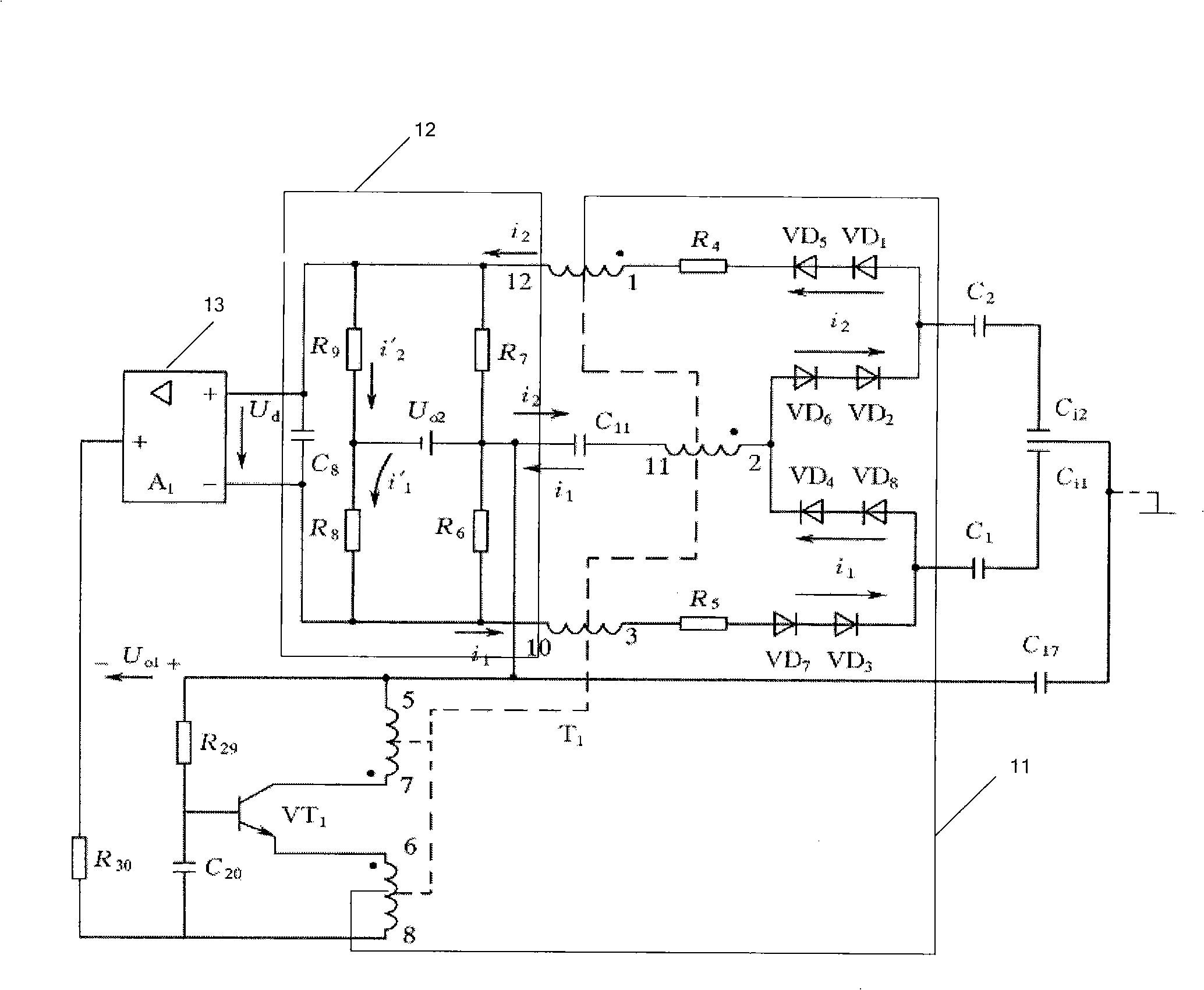

A technology of differential pressure sensor and measurement circuit, which is applied to the pressure difference measurement between multiple valves, and uses electric/magnetic devices to transmit the direction of sensing components and measurement devices, which can solve the problem of low sensor output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings.

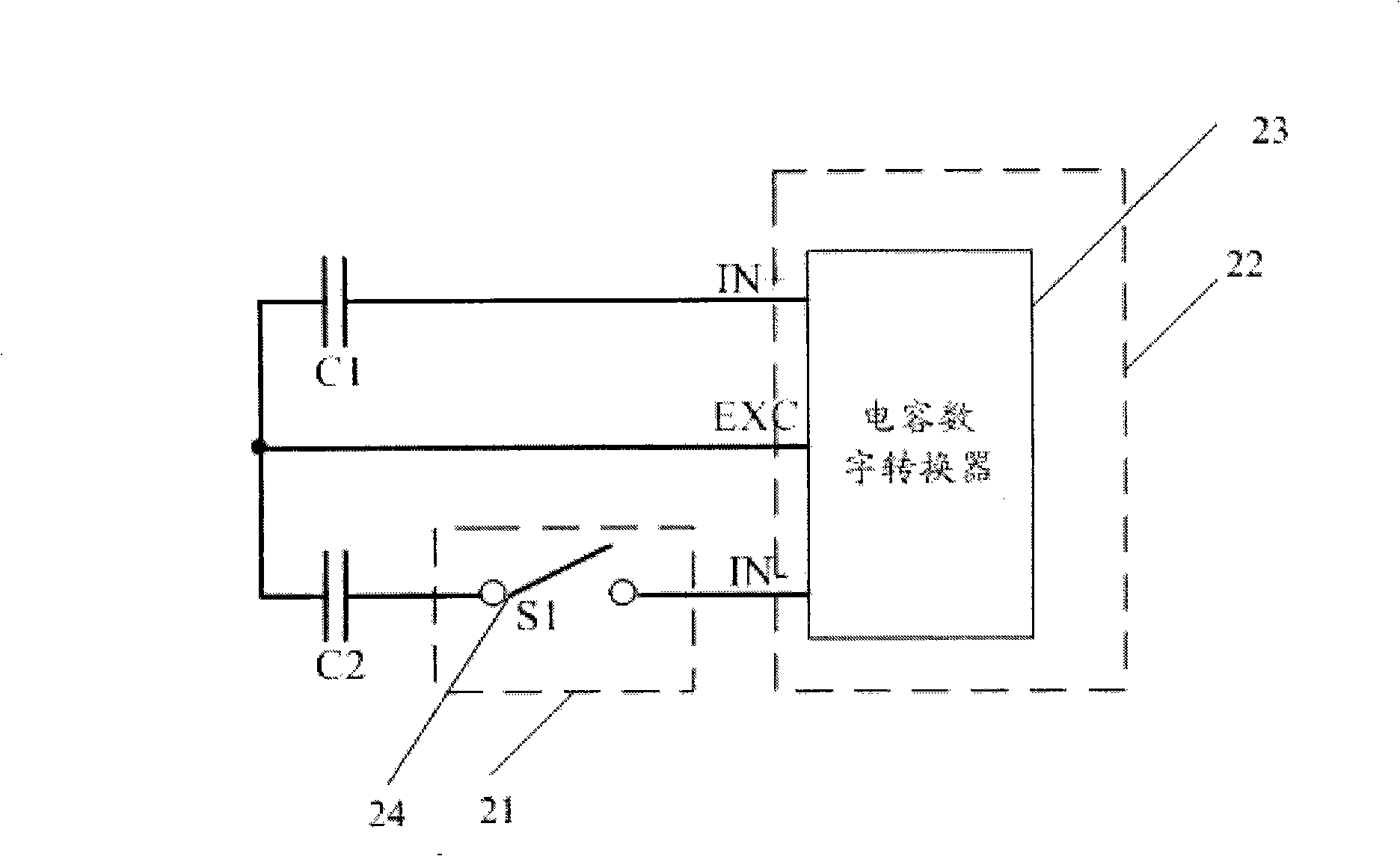

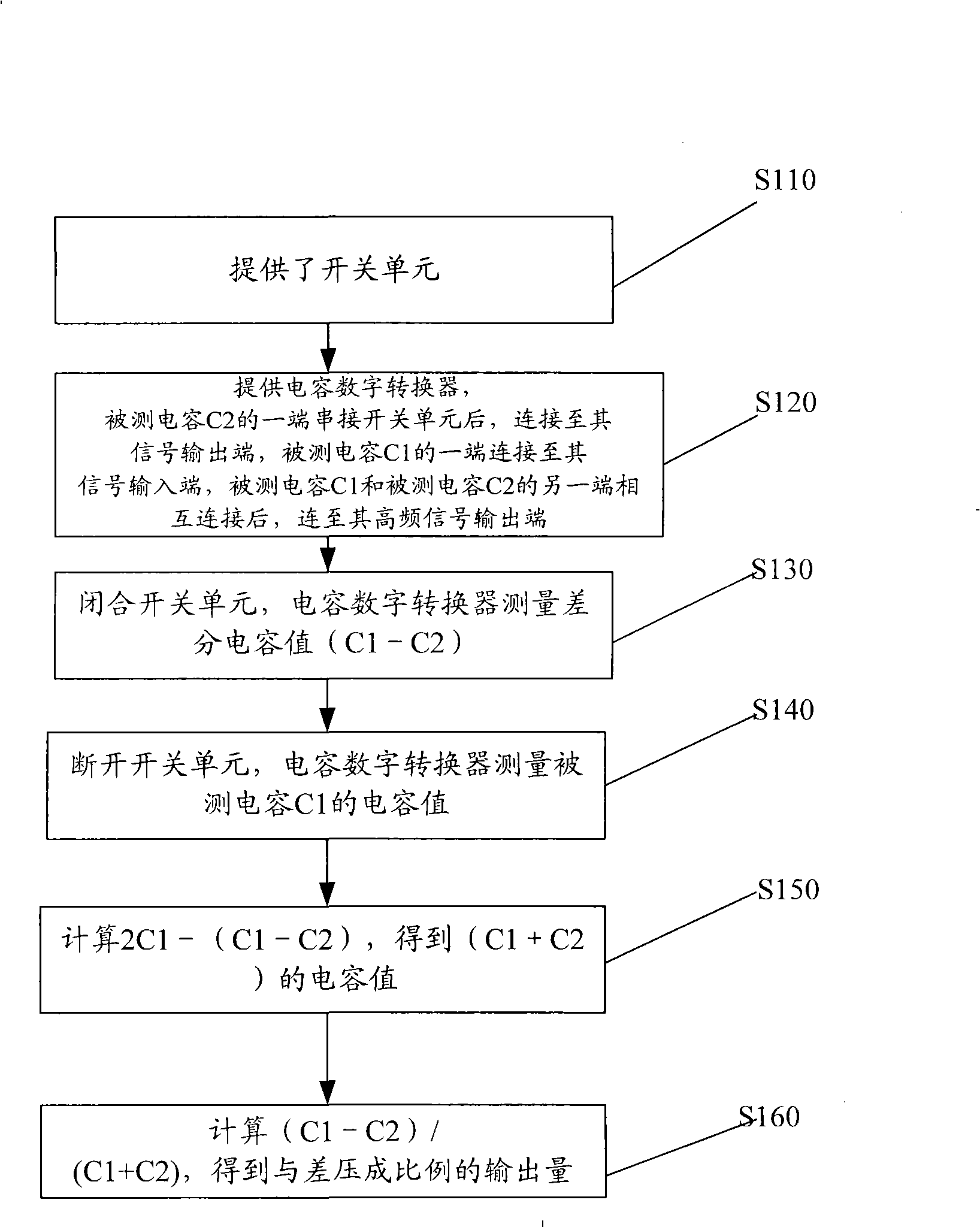

[0048] see figure 2 , which is a structural schematic diagram of the output measurement circuit of the first capacitive differential pressure sensor of the present invention. This measurement circuit is used to measure the sensor output which is proportional to the differential pressure. It includes a switch unit 21 and a capacitance measurement sub-circuit 22, wherein the capacitance measurement sub-circuit 22 includes at least a capacitance-to-digital converter 23, and the capacitance-to-digital converter 23 includes a high-frequency signal output terminal EXC, at least two signal input terminals IN+ and IN -, one end of the measured capacitor C2 corresponding to the negative chamber pressure of the sensor is connected in series with the switch unit 21, and then connected to one signal input terminal IN-, and one end of the measured capacitor C1 corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com