Load charger applied to friction test machine

A friction testing machine and loading device technology, applied in the field of machinery, can solve the problems of inability to realize pulsating impact load, uncontrollable spring elastic force, and inability to load pulsating impact, so as to reduce frictional noise, reduce frictional heat generation, and reduce Effect of small frictional energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

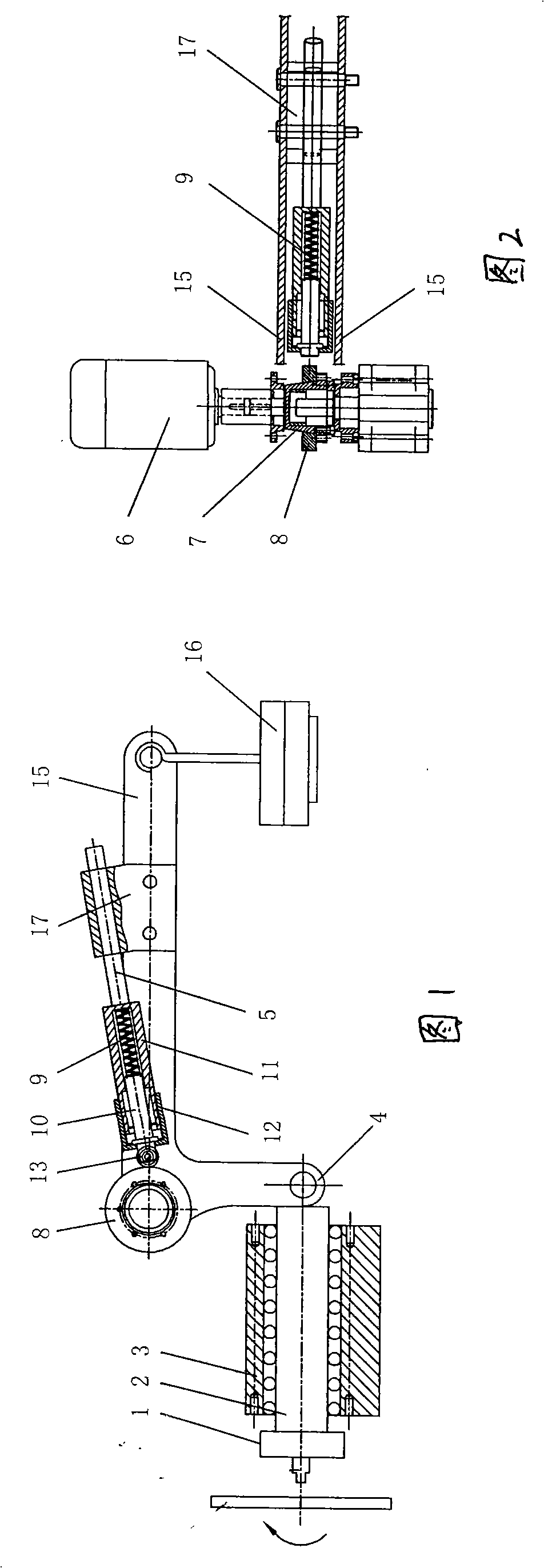

[0016] As shown in Figure 1 and Figure 2, in this load pulsating loading device, the pin sample fixture 1 is fixed at one end of the dowel bar 2, and the rod body of the dowel bar 2 is assembled on the loading device through the bearing 3 in a manner of moving linearly in the axial direction. On the main body, a set of constant load loading device is arranged on the body of the loading device at the other end of the dowel bar 2. The load output head 4 of the constant load loading device loads a constant pressure on the end face of the end. A set of flexible pulsation generating mechanism is added, the flexible pulsation output of the flexible pulsation generating mechanism is superimposed on the load of the constant load loading device, and then applied to the corresponding end surface of the dowel bar through the load output head of the constant load loading device. The flexible pulsation generating mechanism is composed of a reciprocating motion generator and a flexible recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com