Method for compositing cooling tube and fin piece and composition thereof

A combination method and heat pipe technology, applied in the cooling of the instrument, the parts of the instrument, cooling/ventilation/heating transformation, etc., can solve the problems of falling tin material, prolonging the manufacturing time, and affecting the yield in production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

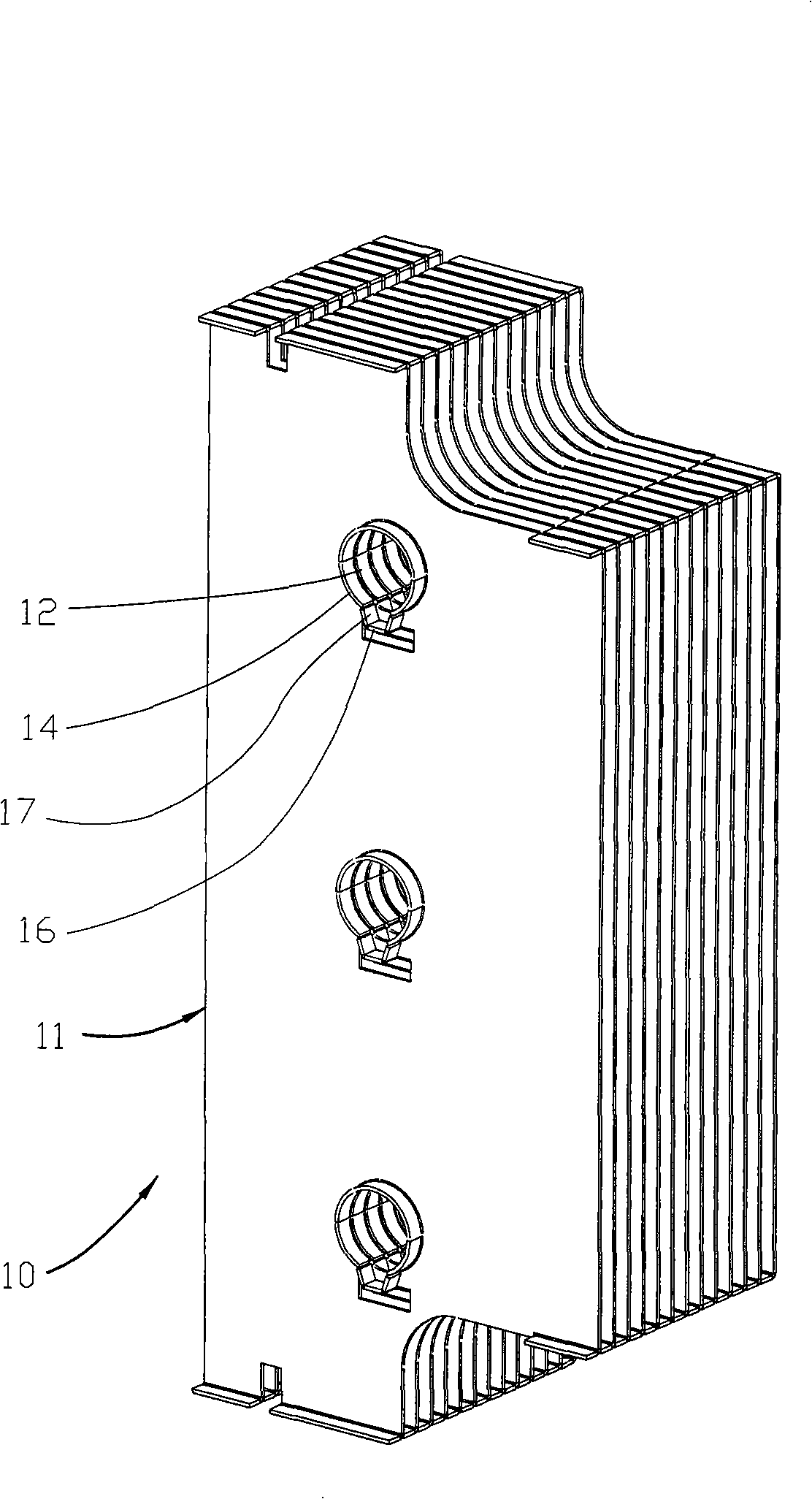

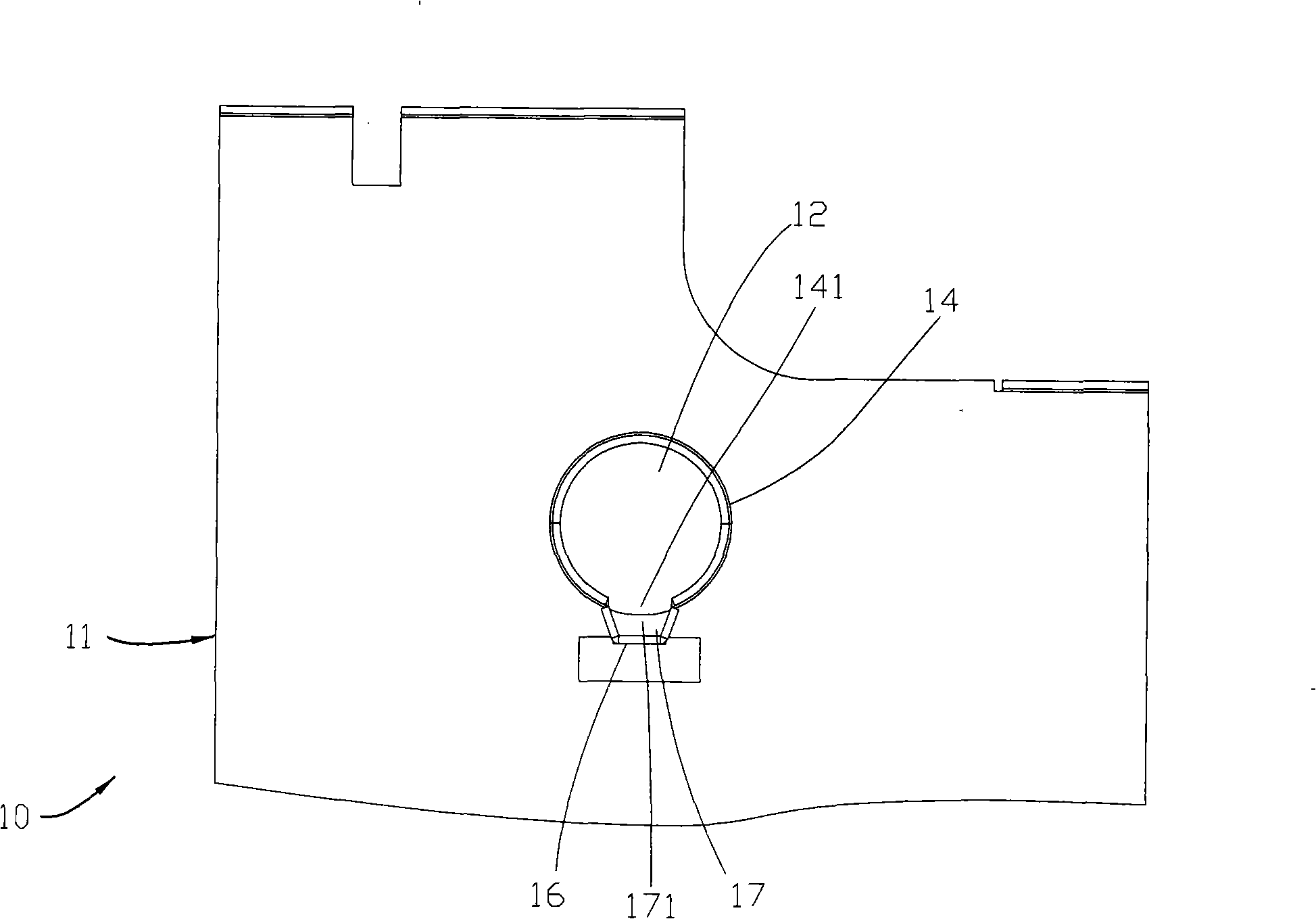

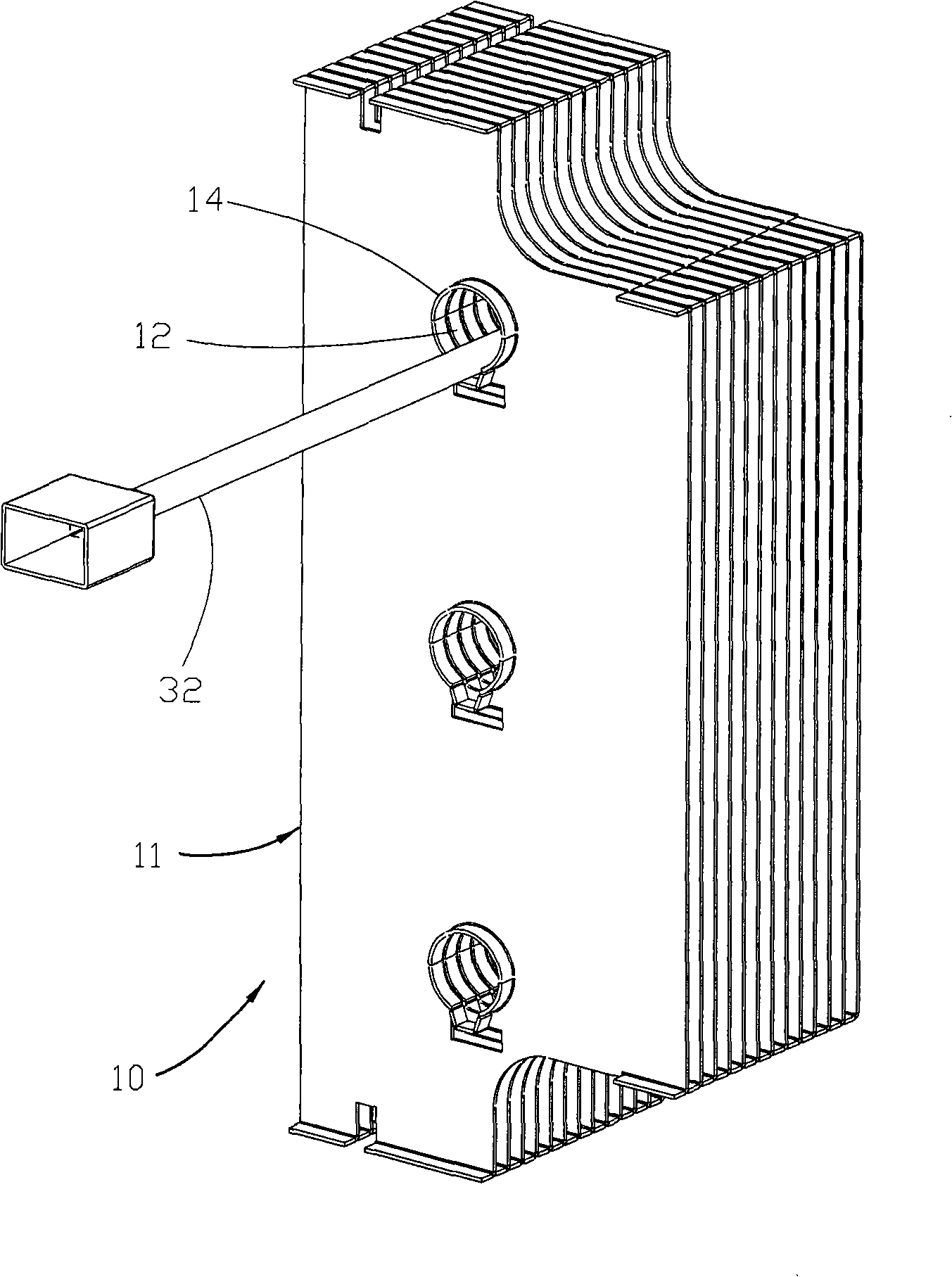

[0020] In order to describe in detail the technical features of the present invention, hereby give the following two preferred embodiments and describe them as follows in conjunction with the accompanying drawings, wherein:

[0021] For the convenience of illustration, in the drawings of the present invention, only one heat pipe 21 is used to represent the state of passing through the through hole 12 .

[0022] Such as Figure 1 to Figure 7 As shown, the method for combining heat pipes and fins provided by the first preferred embodiment of the present invention mainly has the following steps:

[0023] a) Prepare several fins 11 and several heat dissipation pipes 21: the fins 11 are stacked one above the other, each of the fins 11 has several perforations 12, and the perforations 12 on each of the fins 11 correspond to each other And allow these radiating pipes 21 to pass through, each side of each fin 11 extends outwards an extension wall 14 along the periphery of each hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com