A shipping pallet assembly

A technology for transporting pallets and pallets, which is applied in the field of auto parts transportation, can solve problems such as limited protection of car doors, and achieve the effect of stable transportation process and high transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

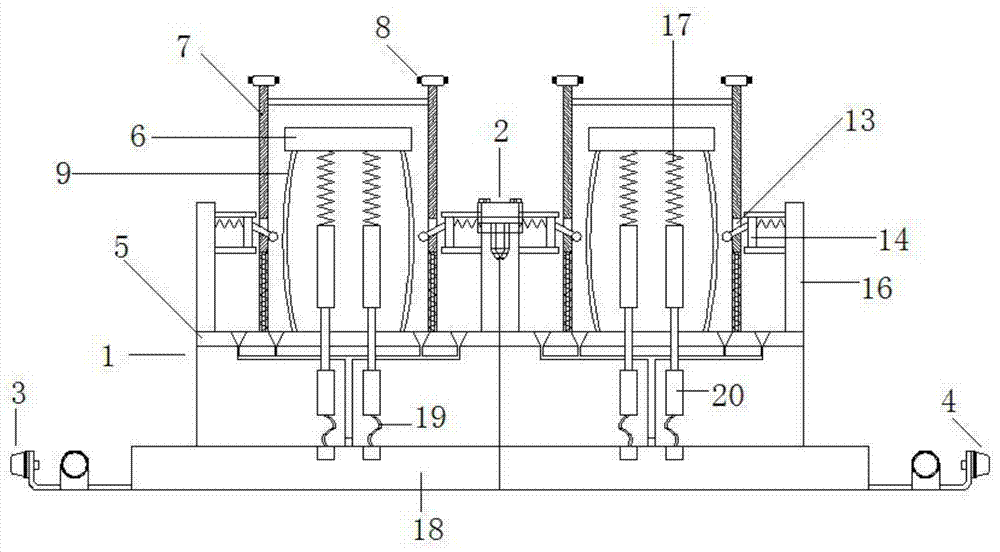

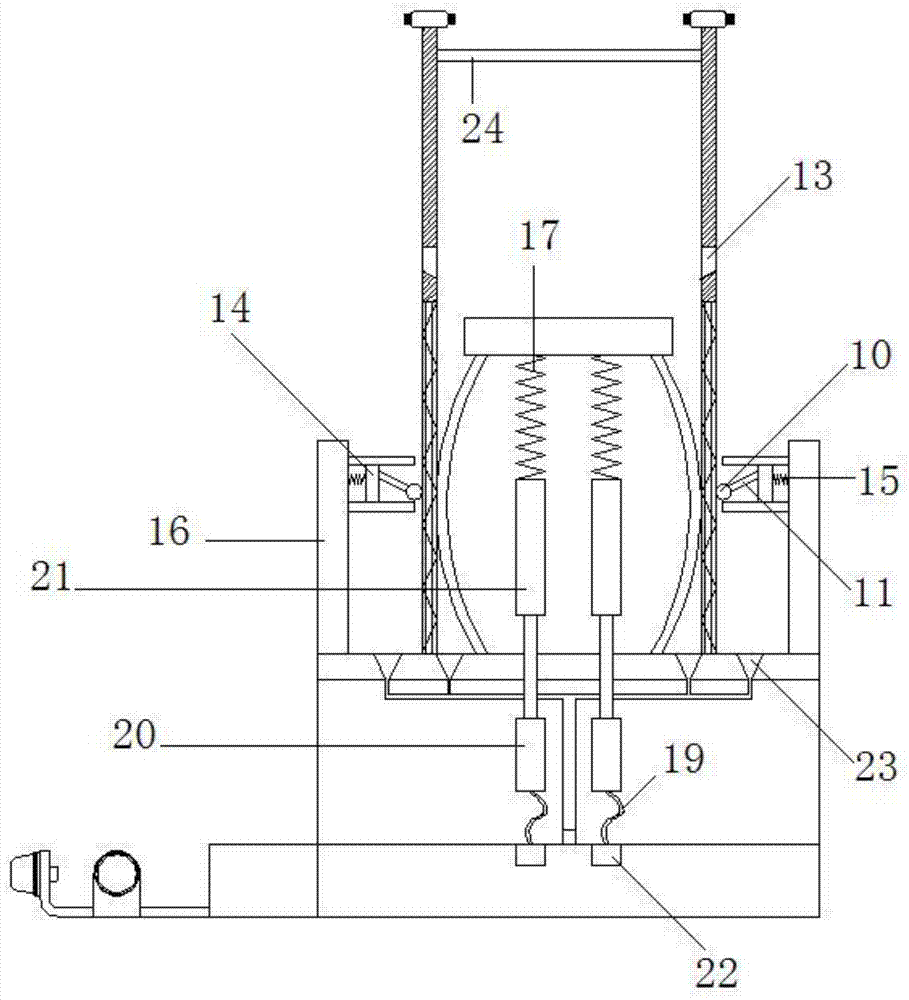

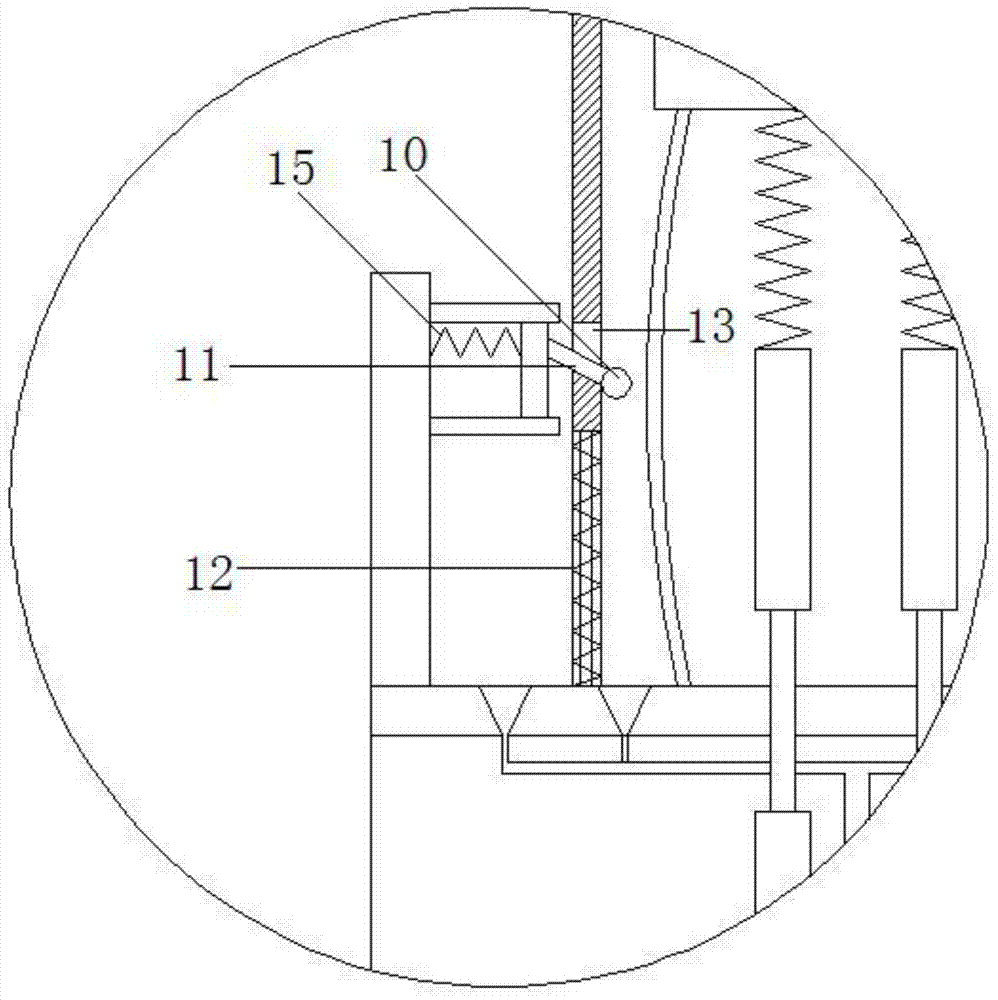

[0021] Such as figure 1 , figure 2 , image 3 In the shown embodiment, a transport pallet assembly includes two pallet bodies 1, and the two pallet bodies are connected to each other through a connecting piece 2 arranged between the two pallet bodies, and one of the pallet bodies is provided with Left anti-collision protection head 3, the other tray body is provided with right anti-collision protection head 4, and described tray body comprises plate seat 5, car door top plate 6, two vertical plates 7, and described vertical plate is provided with car The door surface brush 8, the car door top plate and the two vertical plates form a car door insertion part, the bottom of the car door top plate is provided with a buffer, and the buffer is connected to the disk seat. The connecting parts here can be various conventional connecting and fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com