Discharge lamp

A discharge lamp and electrode technology, which can be applied to discharge lamps, gas discharge lamps, high pressure discharge lamps, etc., can solve the problems of complicated processing and deterioration of manufacturing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

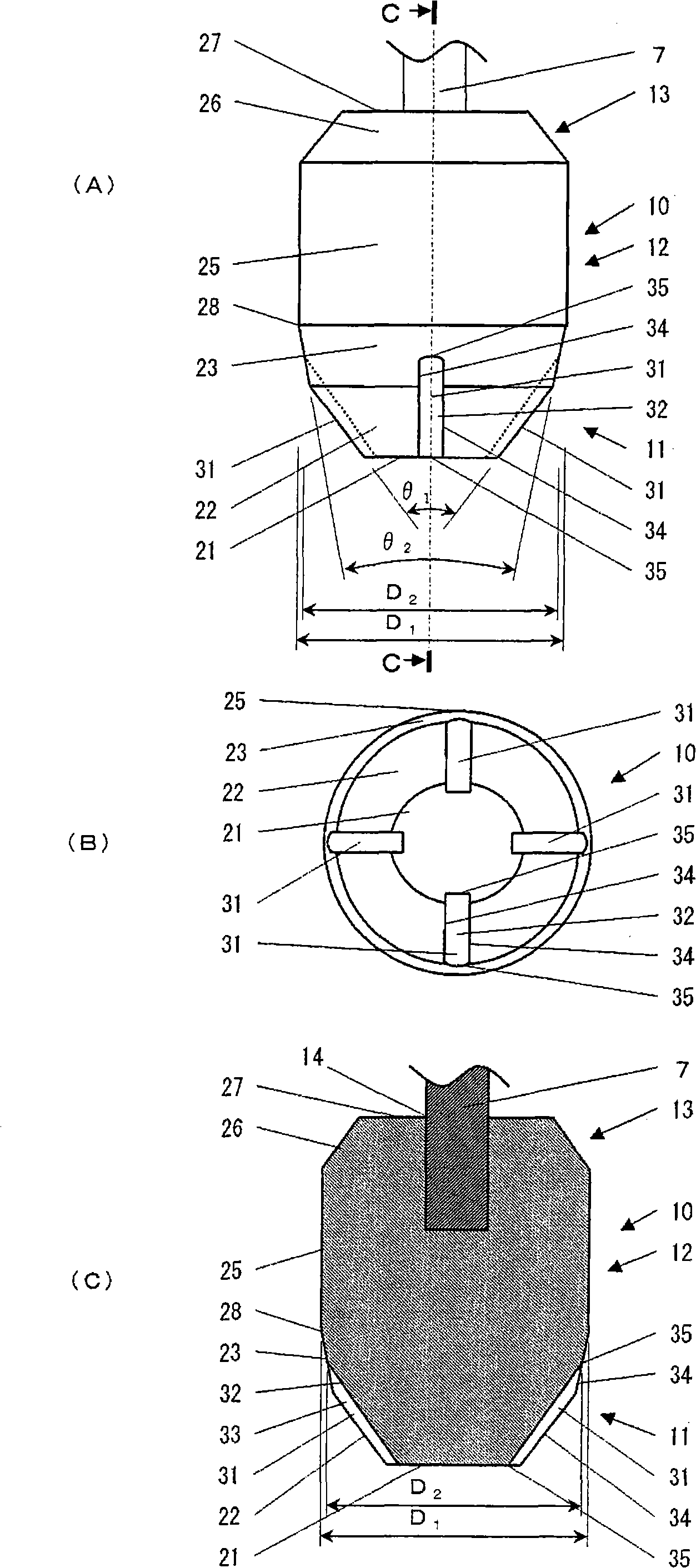

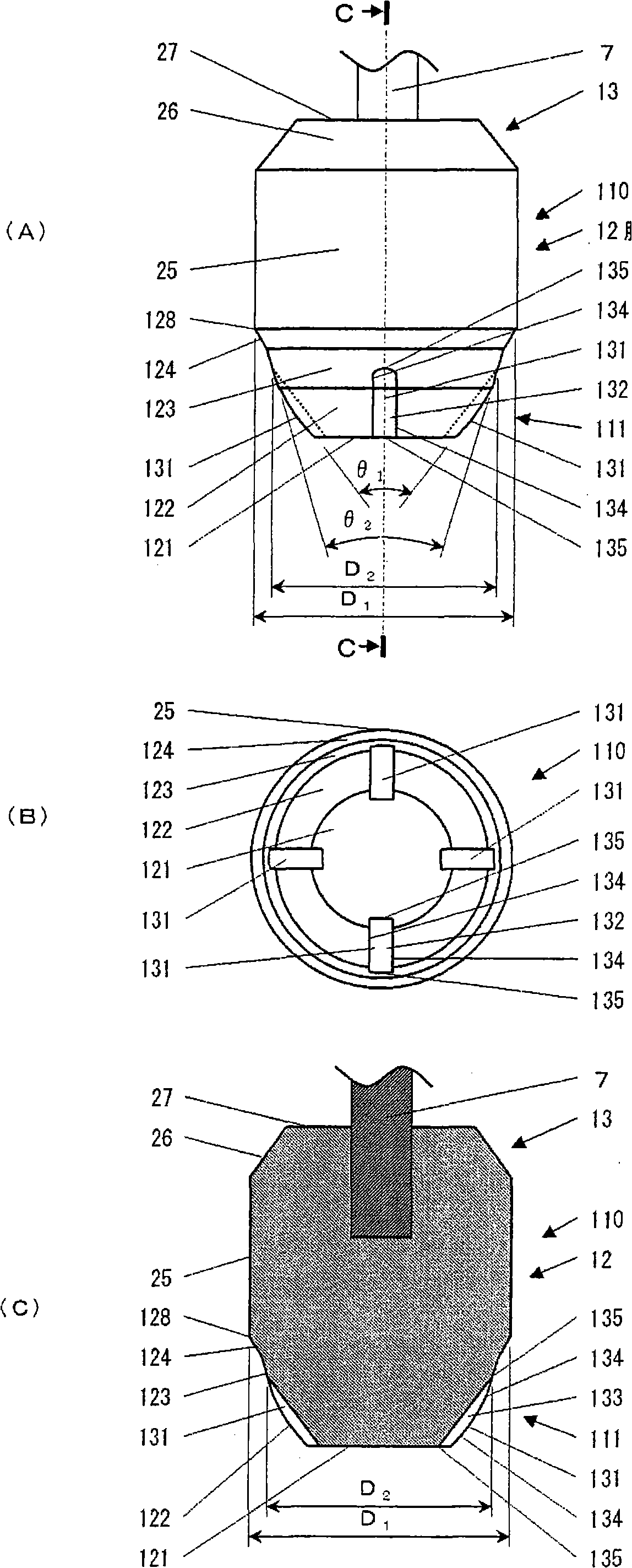

[0026] The anode used in the embodiments of the present invention is: in the range from the front end surface to the taper section, the extension line of the groove neither intersects the main body nor the front end, and is thinner than the main body. A plurality of radial grooves are provided on the side surface.

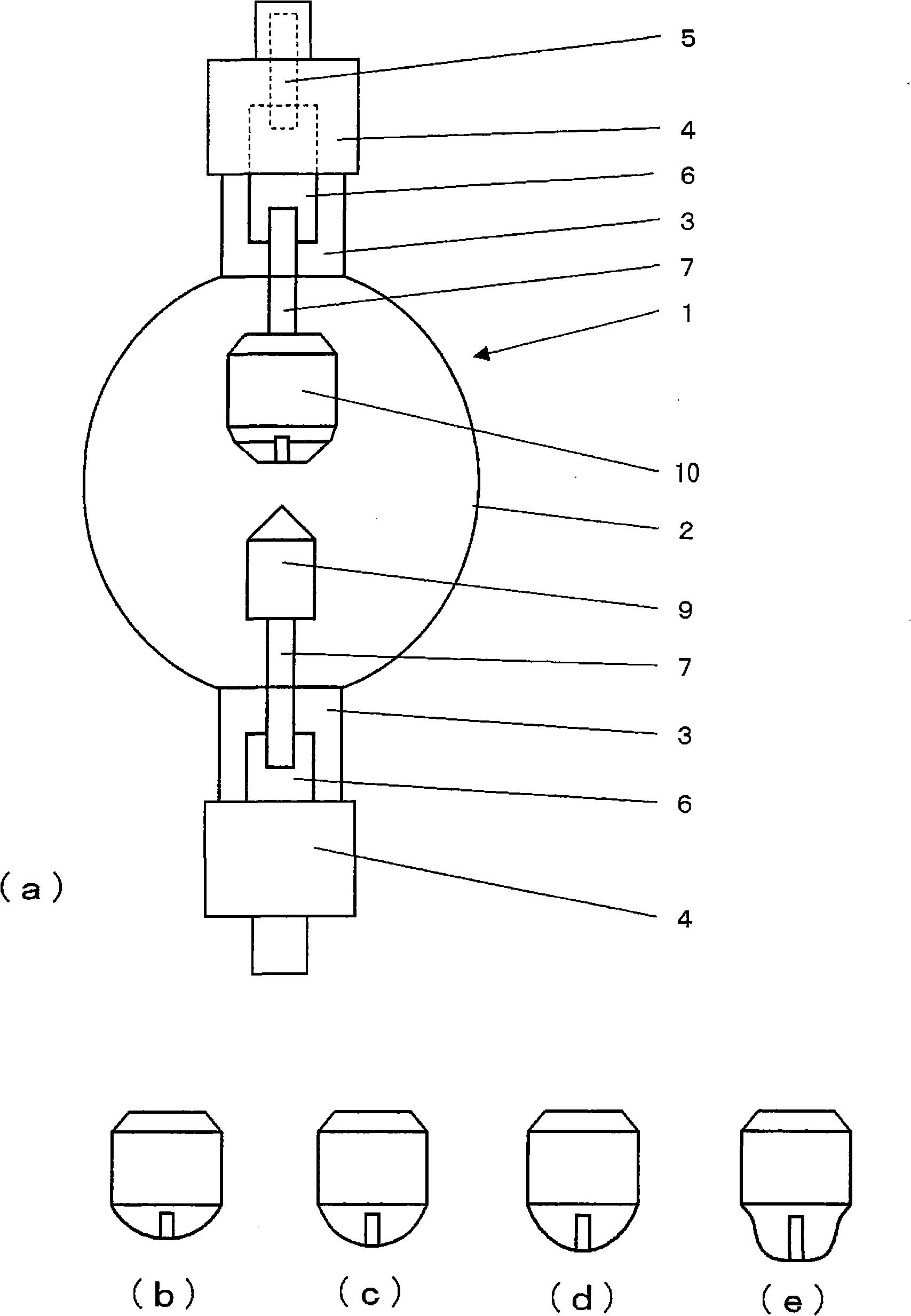

[0027] figure 1 It is an external view of a discharge lamp using an anode according to an embodiment of the present invention, and is a conceptual view showing an electrode shape. exist figure 1 Among them, the discharge lamp 1 is a lamp that discharges between internal electrodes. The light emitting part 2 is a part that emits light by discharge between electrodes, and is a glass member that seals the electrodes to form a discharge space. The sealing tube portion 3 is a portion that hermetically seals the bulb. The base 4 is a part for mechanically holding the lamp and supplying power. The discharge lamp 1 is fixed on the light source device through the lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com