Hoist working mechanism for nacelle

A technology of working mechanism and hoist, applied in the direction of spring mechanism, hoisting device, etc., can solve the problems of long lever, high spring stiffness, and damage of the pressing wheel of the pressing wheel mechanism, so as to reduce the shape and position tolerance and improve the stiffness. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

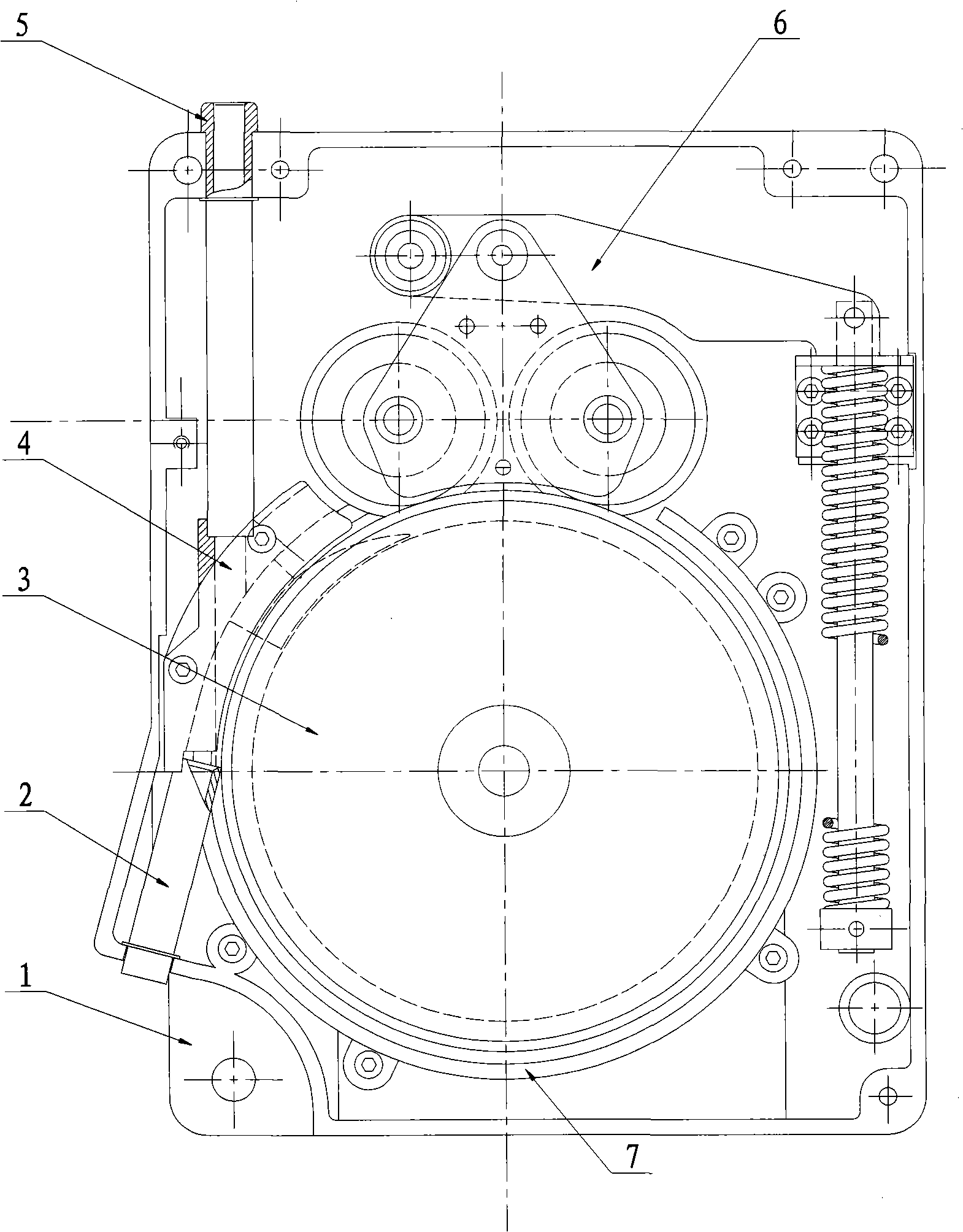

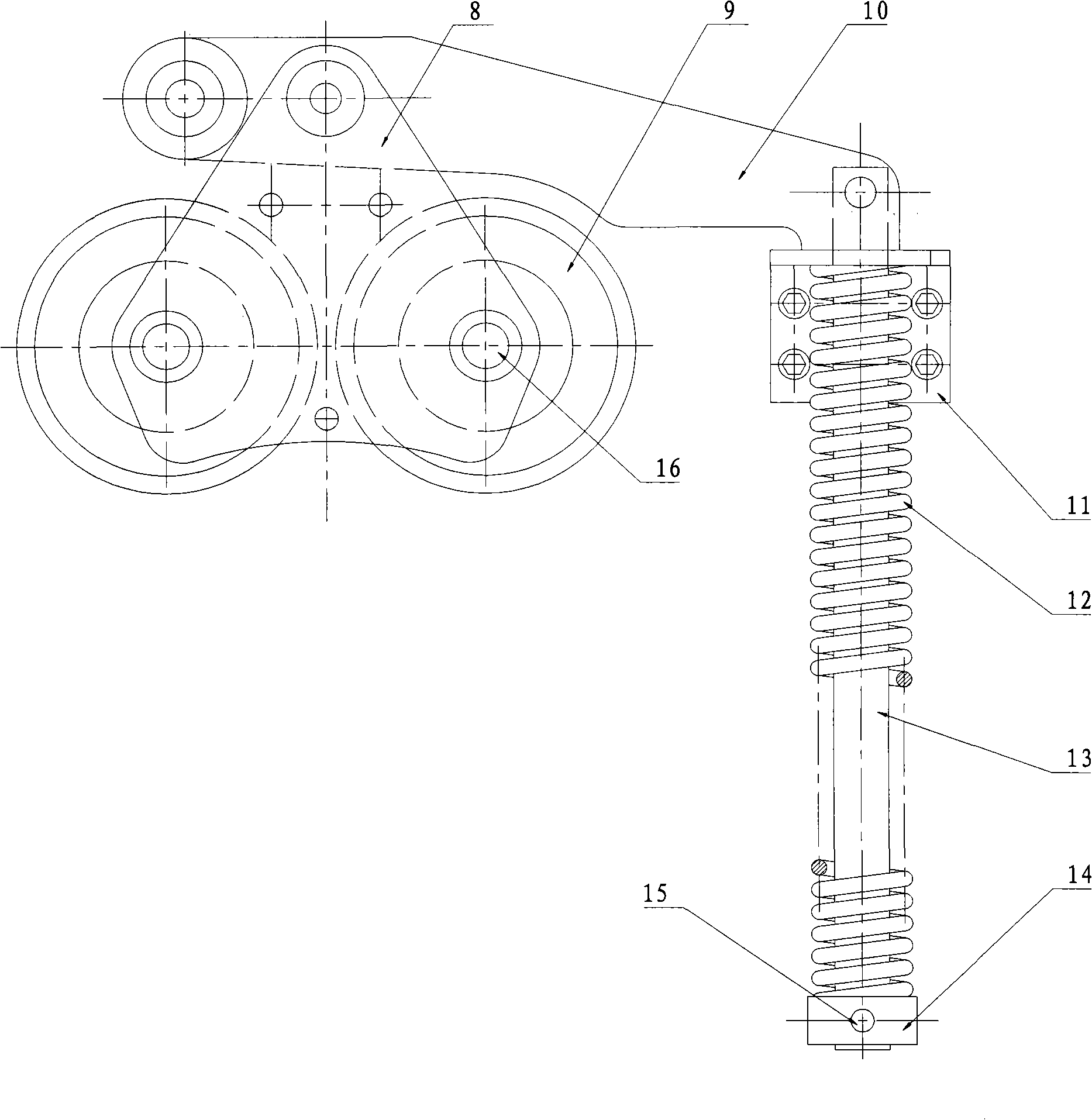

[0011] As shown in the figure: the working mechanism of the hoist for the hanging basket includes a box body 1, a rope inlet 5 located at the top of the box body 1, and a sheave 3 located in the box body 1, and the top of the sheave 3 is arranged Pressing wheel mechanism 6; in said pressing wheel mechanism 6, one end of the lever 10 close to the rope inlet 5 is hinged with the box body 1, and the side plate 8 is hinged at the side near the rope inlet 5 in the middle of the lever 10, and the side plate The bottom of 8 is provided with pinch wheel shaft 16, pinch wheel 9 is installed on pinch wheel shaft 16, and described pinch wheel 9 is pressed on the sheave 3, and the pull bar 13 that can move up and down is equipped with on the other end of lever 10, on said pull bar 13 A spring 12 is sheathed on the top, and a rope outlet 2 is provided on the side of the box body 1 .

[0012] The rope inlet 5 and the rope outlet 2 are tubular respectively, the rope outlet 2 is located below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com