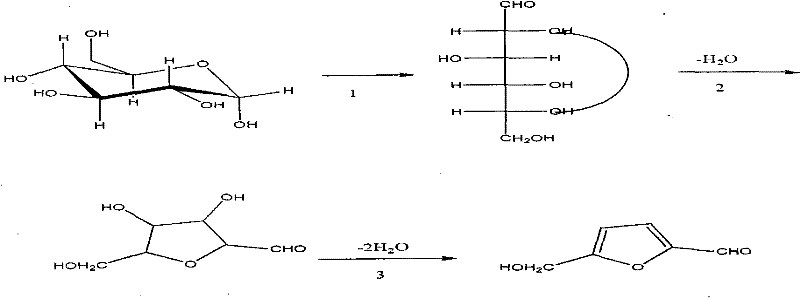

Method for synthesizing 5-hydroxymethyl-furfural

A technology of hydroxymethyl furfural and a synthesis method, applied in the field of bio-organic synthesis of 5-hydroxymethyl furfural, can solve the problems of short supply, high cost, high market price of 5-hydroxymethyl furfural and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Add 40g of chromium chloride and 160g of caprolactam into the flask, heat up (before 60°C, increase the temperature by 20°C per hour, and then increase the temperature by 10°C per hour), and melt to 120°C to become a uniform ionic liquid. Slowly lower the temperature of the configured ionic liquid to below 80° C., add 45 g of glucose (pharmaceutical grade) in batches, and stir while adding. After adding and dissolving evenly, slowly raise the temperature and depressurize (control pressure 0.05-0.07MPa) to dehydrate at the same time. When the temperature rises above 100°C, keep the temperature and continue the reaction and dehydration until no water evaporates. A mixture of dark gray liquids together with ionic liquids.

[0013] Transfer the reaction mixture to a vacuum rectification device while it is hot, keep the system pressure at 150-180KPa and temperature at 90-105°C, and control a certain material transfer rate so that the product, by-product and remaining raw mat...

Embodiment 2

[0016] Add 50g of chromium chloride and 200g of caprolactam into the flask, heat up (before 60°C, increase the temperature by 20°C per hour, and then increase the temperature by 10°C per hour), and melt to 120°C to become a uniform ionic liquid. Slowly lower the temperature of the configured ionic liquid to below 80° C., add 60 g of glucose (pharmaceutical grade) in batches, and stir while adding. After adding and dissolving evenly, slowly raise the temperature, and at the same time depressurize (control pressure 0.05-0.06MPa) for dehydration. When the temperature reaches above 100°C, keep the temperature, continue the reaction and dehydration until no water volatilizes, and obtain the reacted Dark gray liquid in mixture with ionic liquid.

[0017] Transfer the reaction mixture to a set of vacuum distillation equipment while it is hot, keep the system pressure at 150-160KPa and temperature at 95-103°C, control a certain material transfer rate, and completely separate the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com