Improved device for regenerating and processing waste lubrication oil

A waste lubricating oil and processing device technology, applied in the petroleum industry, lubricating composition, hydrocarbon distillation, etc., can solve problems such as complex structure, difficult control of heating temperature, uneven heating area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

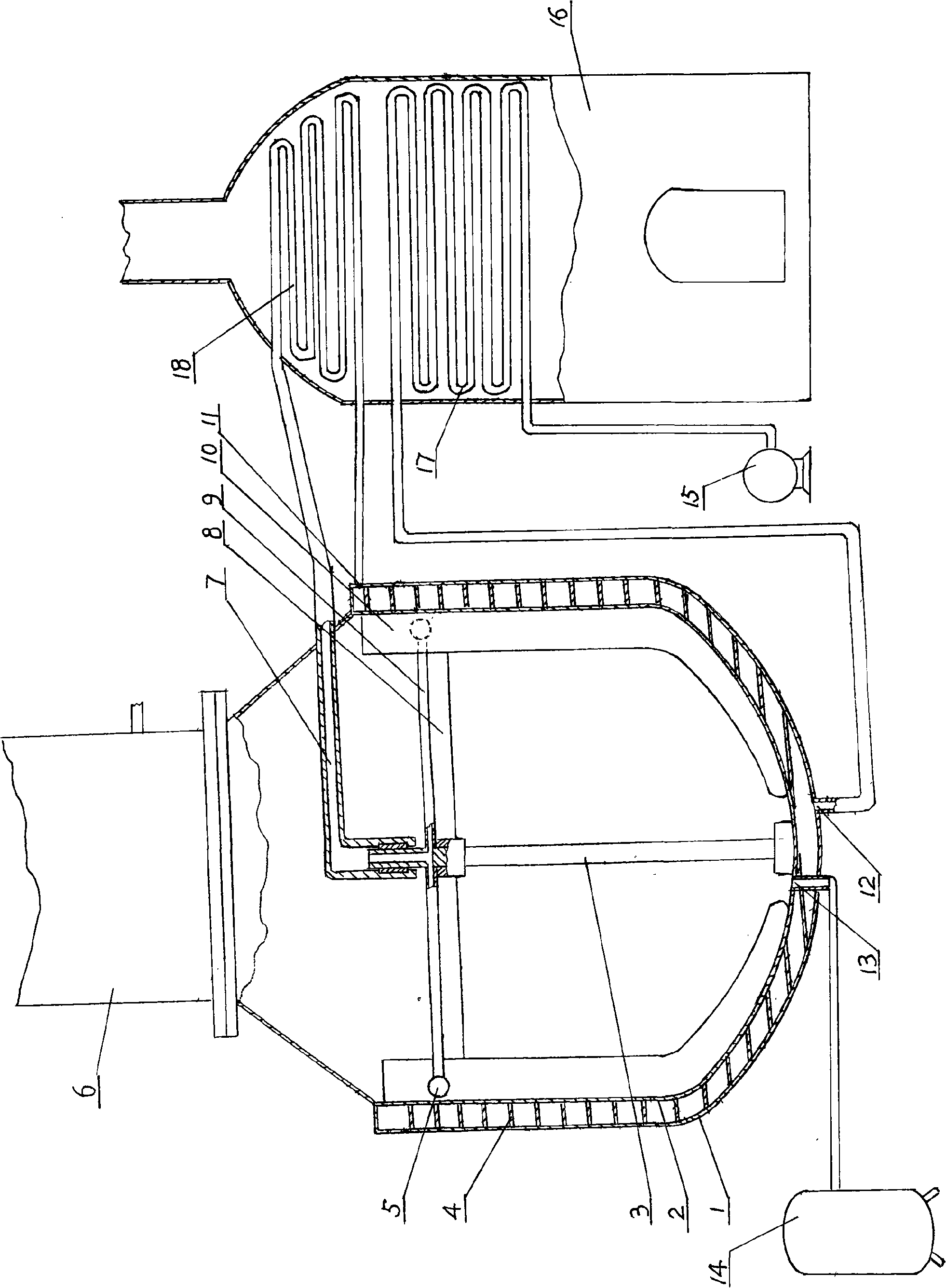

[0009] An improved waste lubricating oil regeneration processing device, as shown in the accompanying drawings, includes an evaporator with a closed heating interlayer, which is a closed shell of a combined rotator, and a fine The distillation column 6 is provided with an oil inlet 12 and an oil outlet 11 at the bottom and upper part of the evaporator heating interlayer shell 1 respectively, and a central rotating shaft 3 with an oil inlet passage is installed at the center of the bottom center of the evaporator liner 2 through a bearing, and the center The upper end of the rotating shaft 3 cooperates with the sealed bearing fixed at the end of the oil guide pipe 7 above the evaporator, and the central rotating shaft 3 is respectively installed with the inner wall of the inner tank 2 through the ends of the symmetrical bracket 8 with the oil pipe 9. The symmetrical scraper 10, the oil guide pipe 7 communicates with the oil pipe 9, and the symmetrical injectors 5 communicated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com