Chopping block type scissor for loom for shearing fabric in chopping manner

A loom and scissors technology, applied in looms, auxiliary equipment for weaving, textile and other directions, can solve the problems of weft slippage, inability to cut fabrics well, and scissors wear quickly, etc. Cutting effect and economic effect, the effect of protecting the cutting edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

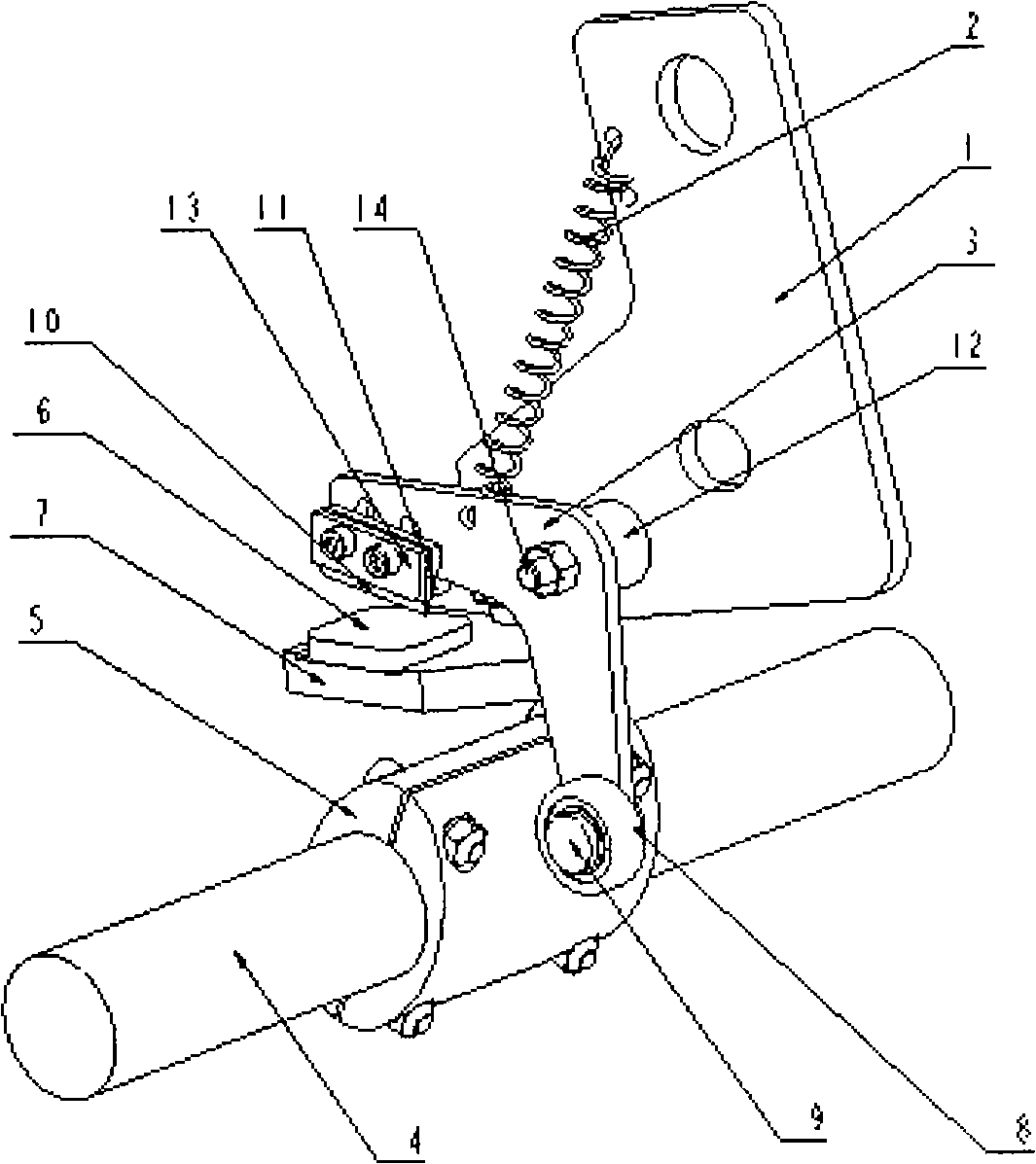

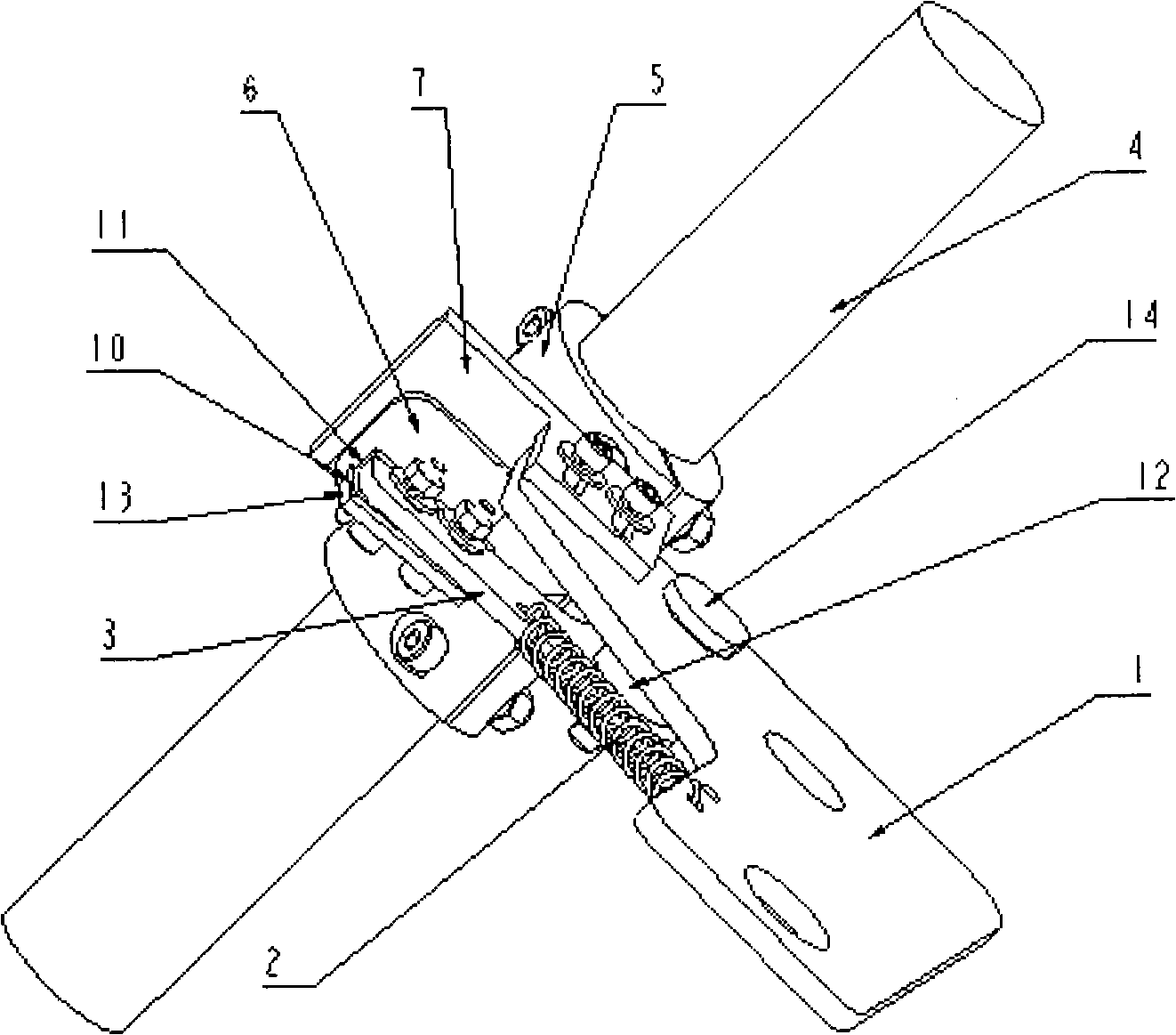

[0008] An anvil-type scissors device for a loom that cuts fabrics by chopping, including a static blade seat 1, a spring 2, a moving blade seat 3, a detection shaft 4, a scissors cam 5, a PU rubber pad 6, and an anvil-type support Seat 7, bearing 8, eccentric shaft 9, blade 10, blade fixed pressing plate 11, nylon sleeve 12, blade pressing plate 13, movable blade seat rotary central axis 14. The detection shaft 4 is provided with a scissors cam 5, the eccentric shaft 9 is provided with a bearing 8 and a movable blade seat 3, and the bearing 8 is in contact with the scissors cam 5; the movable blade seat 3 is provided with a blade 10, and blades 10 are provided on both sides Fixed pressing plate 11 and blade pressing plate 13; spring 2 and rotating center axis 14 of moving blade seat 3 are also arranged on moving blade seat 1; PU rubber pad 6 and chopping board type bracket 7 are arranged on static blade seat 1, and static blade seat 1 is fixed On the loom; the static blade sea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com