Tube fin type heat exchanger of side positioned longitudinal whorl generator

A technology of longitudinal vortex generator and tube-fin type, which is applied to heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problems of increased pump power consumption and increased resistance, and achieve increased resistance and reduced shape Resistance, enhancing the effect of fluid turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

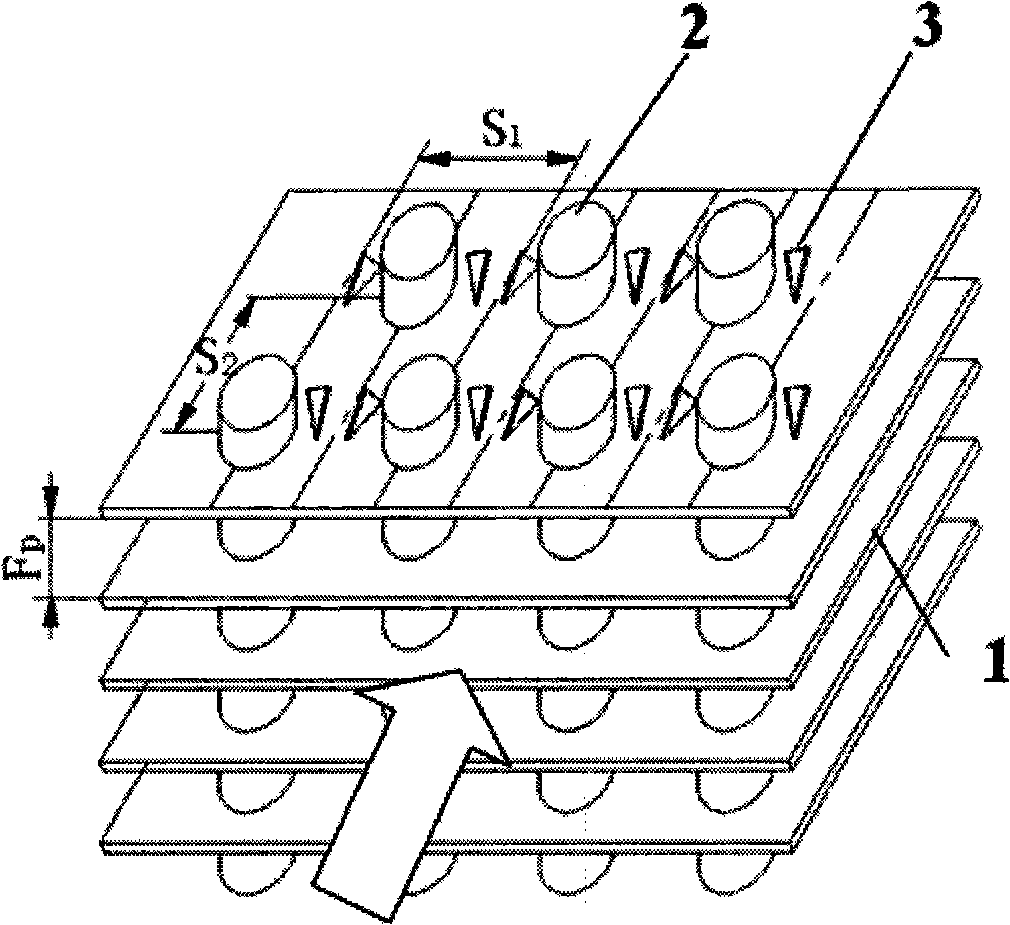

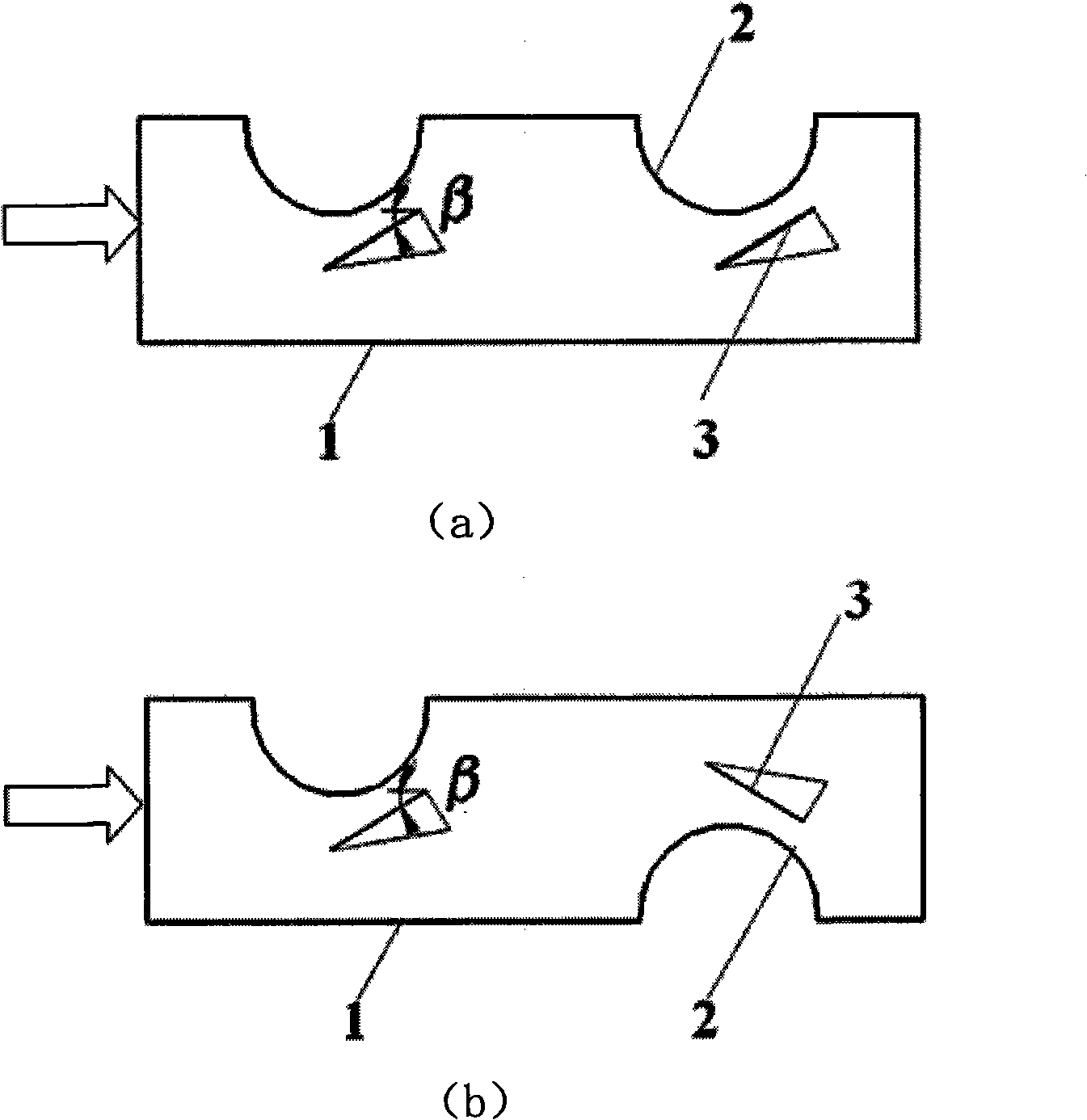

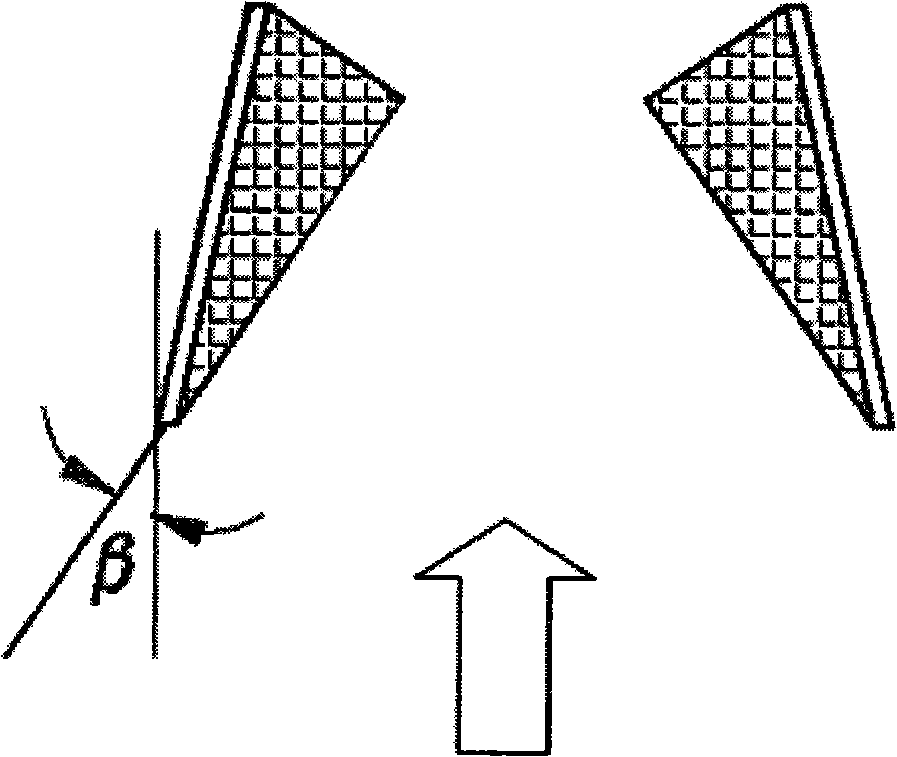

[0019] See figure 1 , The present invention includes parallel to each other and separated by a certain distance F p Several groups of flat substrates [1], and two or more rows of heat exchange tubes [2] passing through the flat substrates [1] vertically, on both sides of each heat exchange tube [2] There are triangular winglets [3] symmetrically, and the triangular winglets [3] constitute the longitudinal vortex generator. The longitudinal tube spacing of the heat exchange tube is S 2 Greater than the transverse pipe spacing S 1 .

[0020] When working, the liquid medium goes inside the tube; the air medium goes outside the tube. The heat transfer and convection of the heat exchange tube [2], the flat substrate [1], and the delta wing [3] realize the heat exchange of the two media. Due to the action of the triangular winglet [3] longitudinal vortex generator, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com