Method for simulating hot test chip thermal resistance value

A technology of thermal resistance and thermal testing, which is applied in the direction of measuring devices, material thermal development, instruments, etc., can solve the problems that the heating state and thermal resistance of the thermal test chip cannot be truly displayed, and the heat dissipation quality of the heat dissipation module is difficult to ensure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

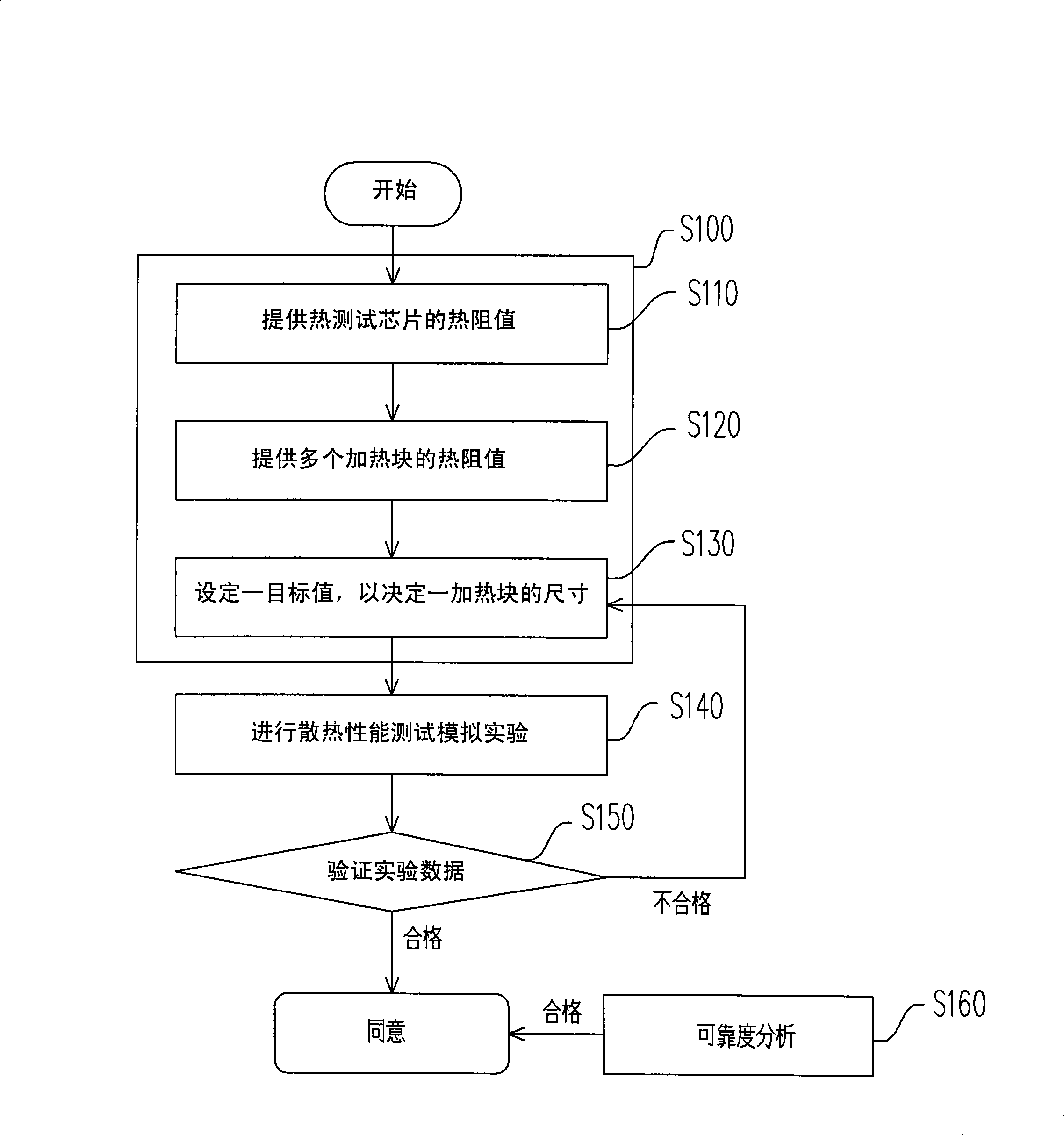

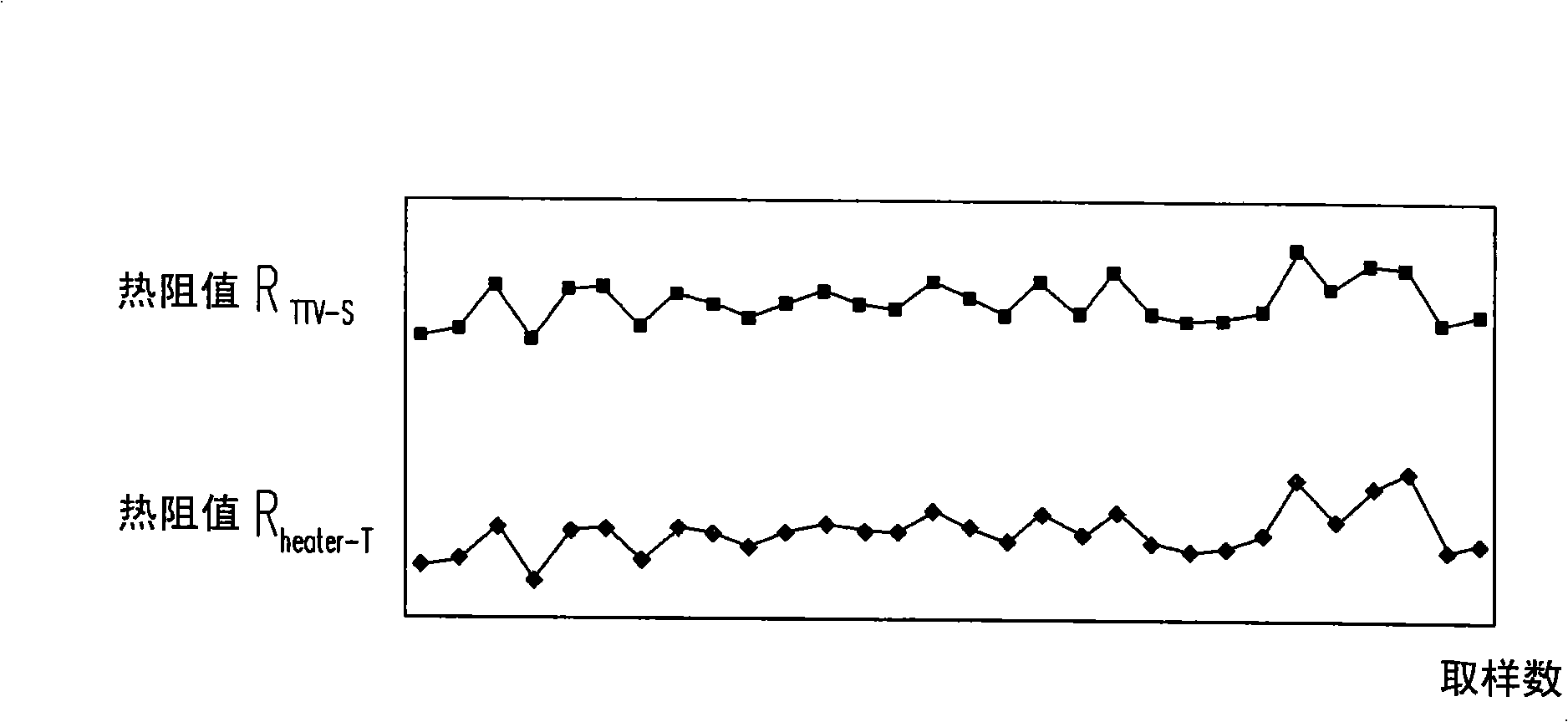

[0021] The method for simulating the thermal resistance of a thermal test chip according to the present invention is mainly applied in a computer mainframe or a server mainframe for evaluating the thermal resistance R of a heating block. heater and the thermal resistance of the thermal test chip R TTV The correlation between them is used as a method to quickly test the heat dissipation performance of the heat dissipation module. Applying this method can not only ensure that the heat dissipation modules produced meet the system design requirements, improve the quality of mass production, but also greatly reduce the sample testing time.

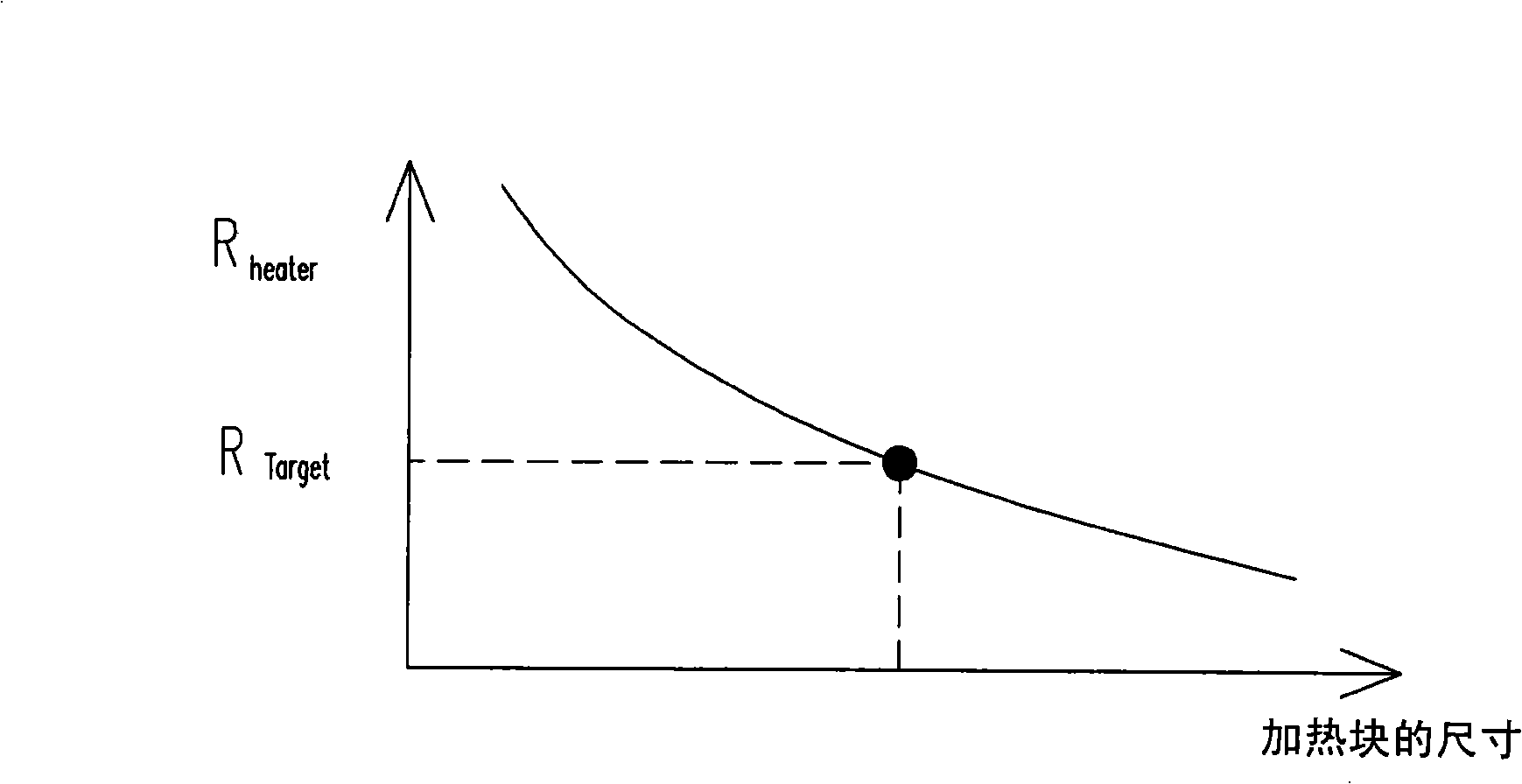

[0022] Since the heating block is a material with uniform heat conduction, and the corresponding relationship between the size of the heating block and its thermal resistance value can be found through the regression analysis theory to find the corresponding function curve to set the thermal resistance value R of the simulated thermal test chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com