Gas flow passage structural of fuel batter with proton exchange film

A proton exchange membrane and fuel cell technology, which is applied to fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., can solve problems such as uneven gas distribution, improve the problem of uneven gas distribution, and solve the problem of uneven gas distribution. problem, reduce the effect of a large increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

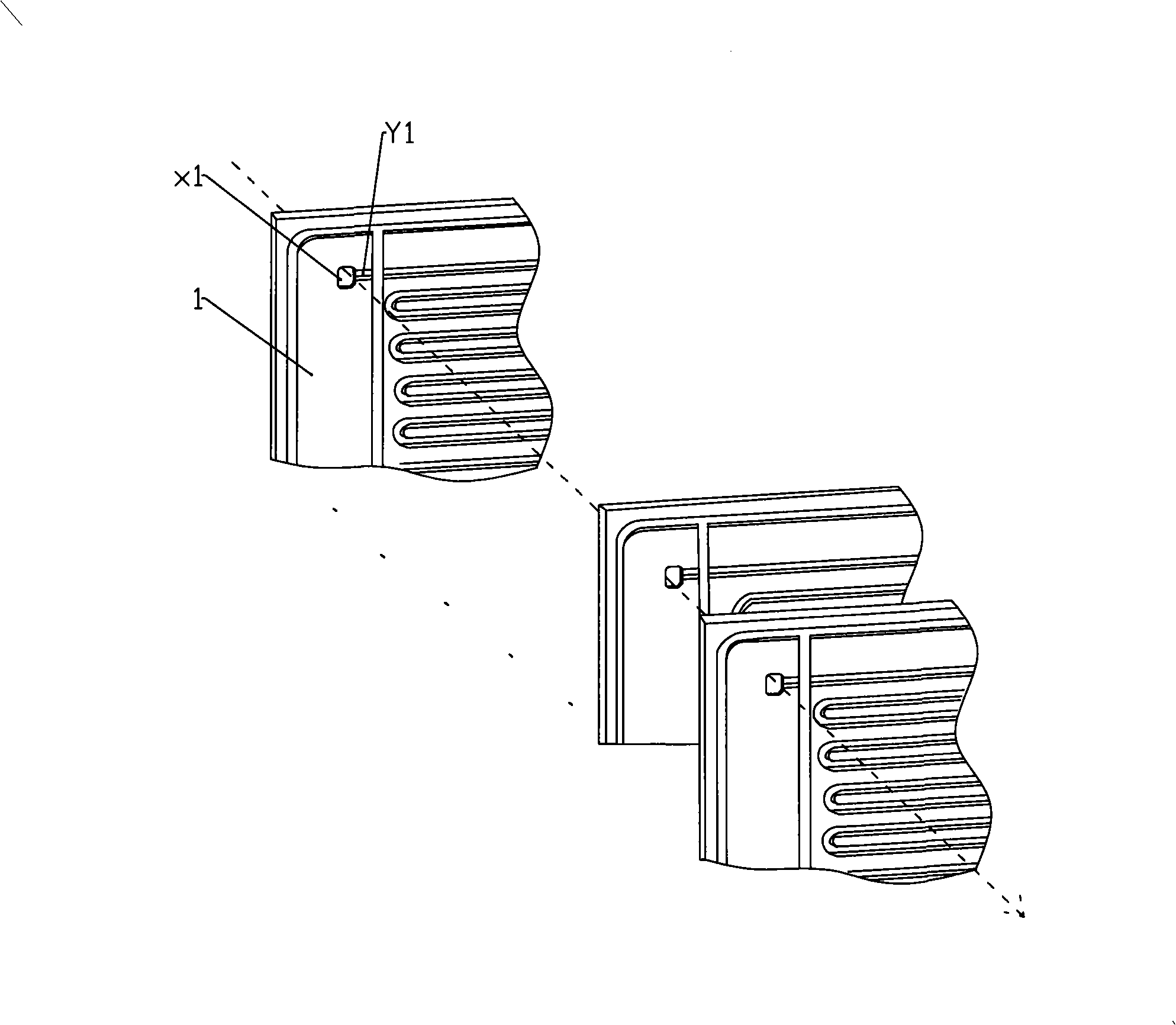

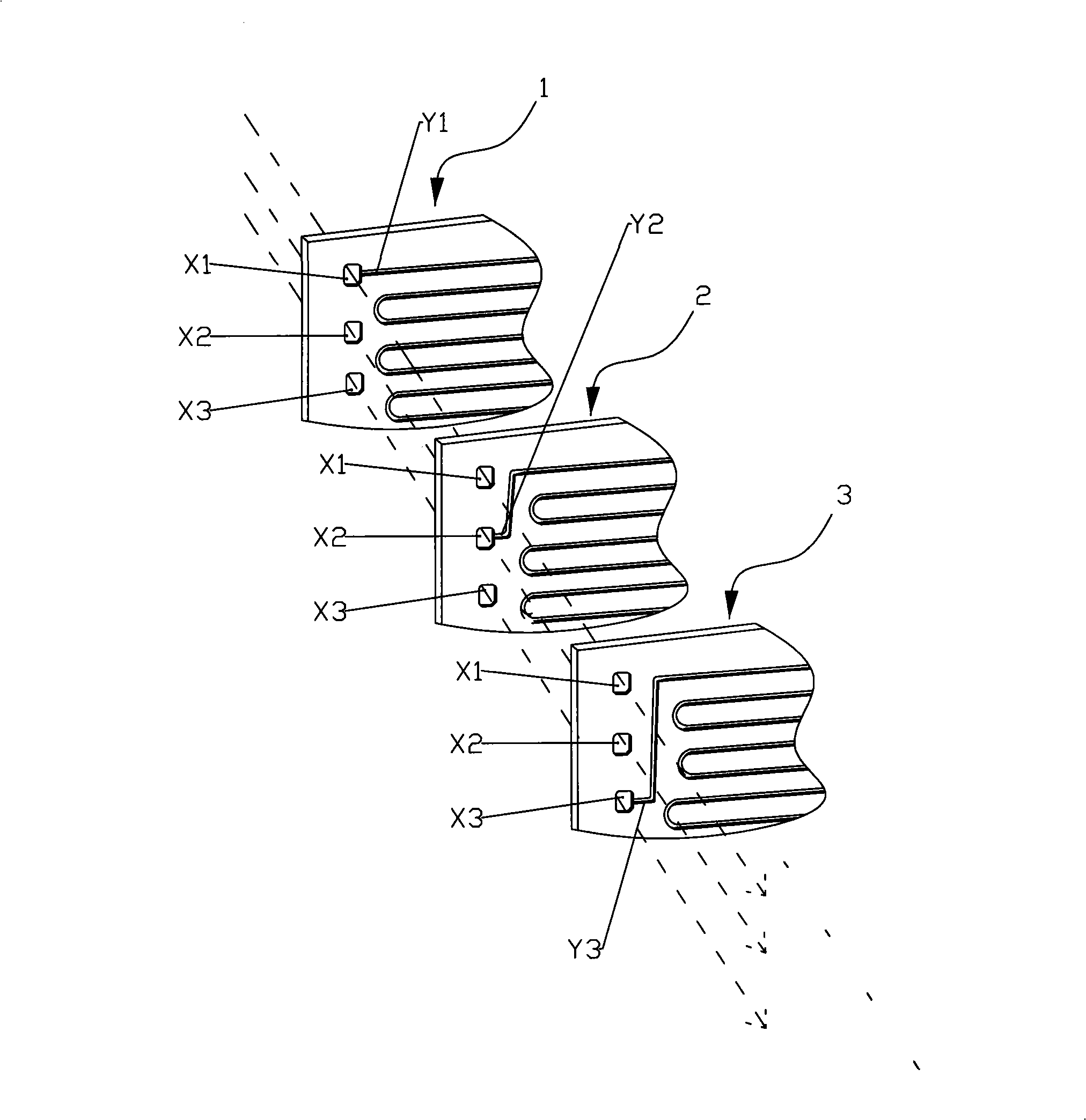

[0014] like figure 2 As shown, a proton exchange membrane fuel cell stack is formed by stacking three groups of battery cells, that is, the first group of battery cells 1, the second group of battery cells 2, and the third group of battery cells 3 are stacked in sequence, and each group The battery unit can use one basic battery unit or be formed by stacking 2 to 5 basic battery units. At the same time, three fuel gas intake shaft channels are set, which are respectively X1, X2, and X3, forming three independent fuel gas intake shaft channels.

[0015] All the basic battery units in the first group of battery units 1 communicate with the shaft channel X1 through the gas inlet Y1 on the fuel gas deflector, but are blocked from the other two shaft channels X2 and X3.

[0016] All t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com