Photovoltaic cell

A photovoltaic cell and semiconductor technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of expensive device manufacturing costs, achieve the effects of improving efficiency, saving exchange time, and avoiding room condition adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

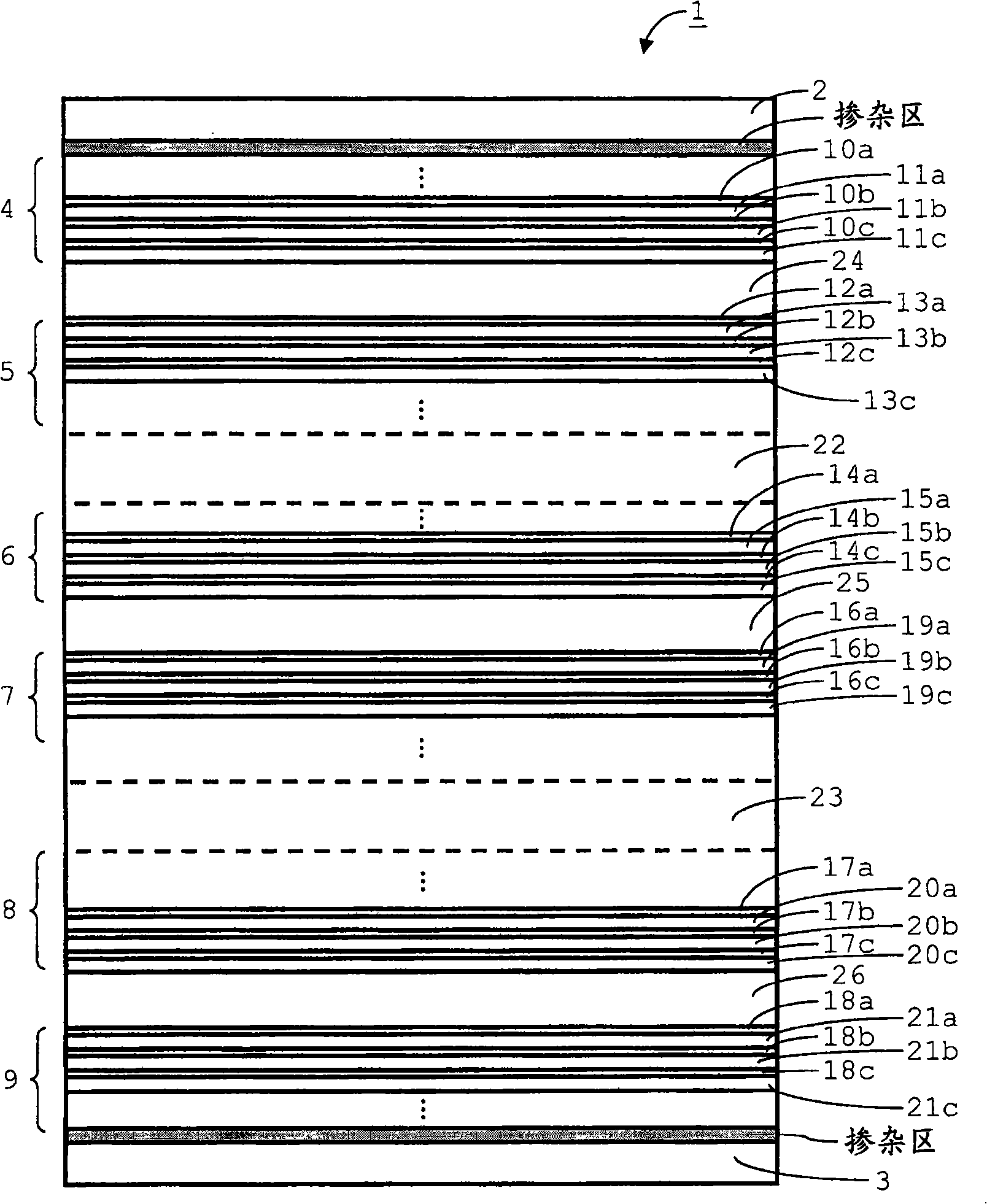

[0035] figure 1 The photovoltaic cell 1 is shown only to the extent necessary to illustrate the present invention. In a practical photovoltaic device, the photovoltaic cell 1 will be encased in other layers including one or more layers of plastic foil and / or glass sheets for isolating the photovoltaic cell from the environment. In the illustrated embodiment, the photovoltaic cell 1 is a tandem cell, ie a stack of component cells. In this case, the individual cells in the stack are electrically connected in series. Paralleling is an alternative, but more complicated.

[0036] The illustrated photovoltaic cell 1 is a two-terminal device and comprises a top electrode 2 and a back electrode 3 . The top electrode is made of transparent conductive material such as SnO 2 (tin oxide), ITO (indium tin oxide), ZnO (zinc oxide), Zn 2 SnO 4 (zinc stannate), Cd 2 SnO 4(cadmium stannate) or InTiO (indium titanium oxide). The back electrode 3 is at least partially made of a metal su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com