Hollow motor drive device

A motor-driven, hollow technology, applied in the direction of transmission, electromechanical devices, electric components, etc., can solve the problems of high rigidity, narrow application range, and large device shape, and achieve high rigidity, easy assembly and adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

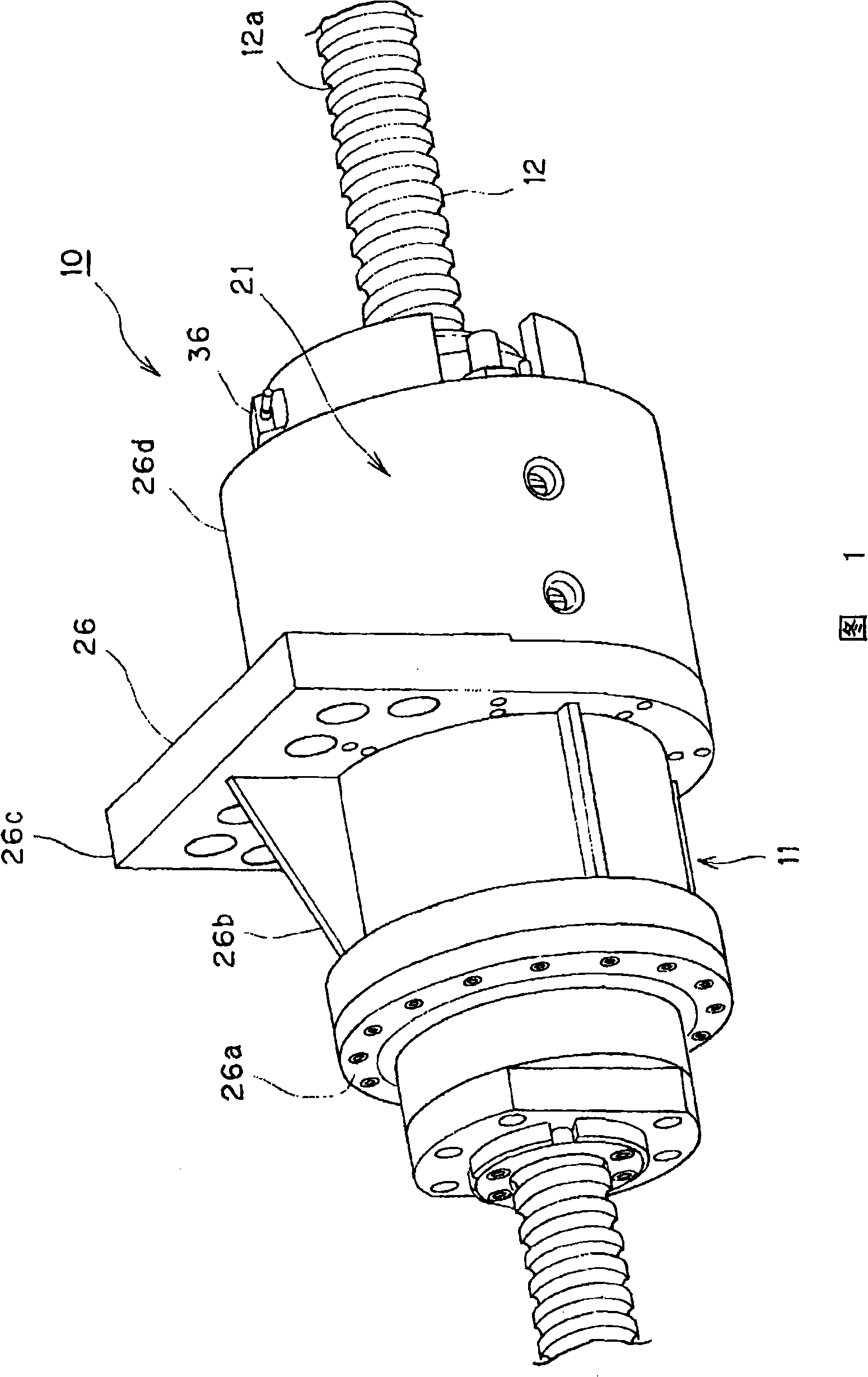

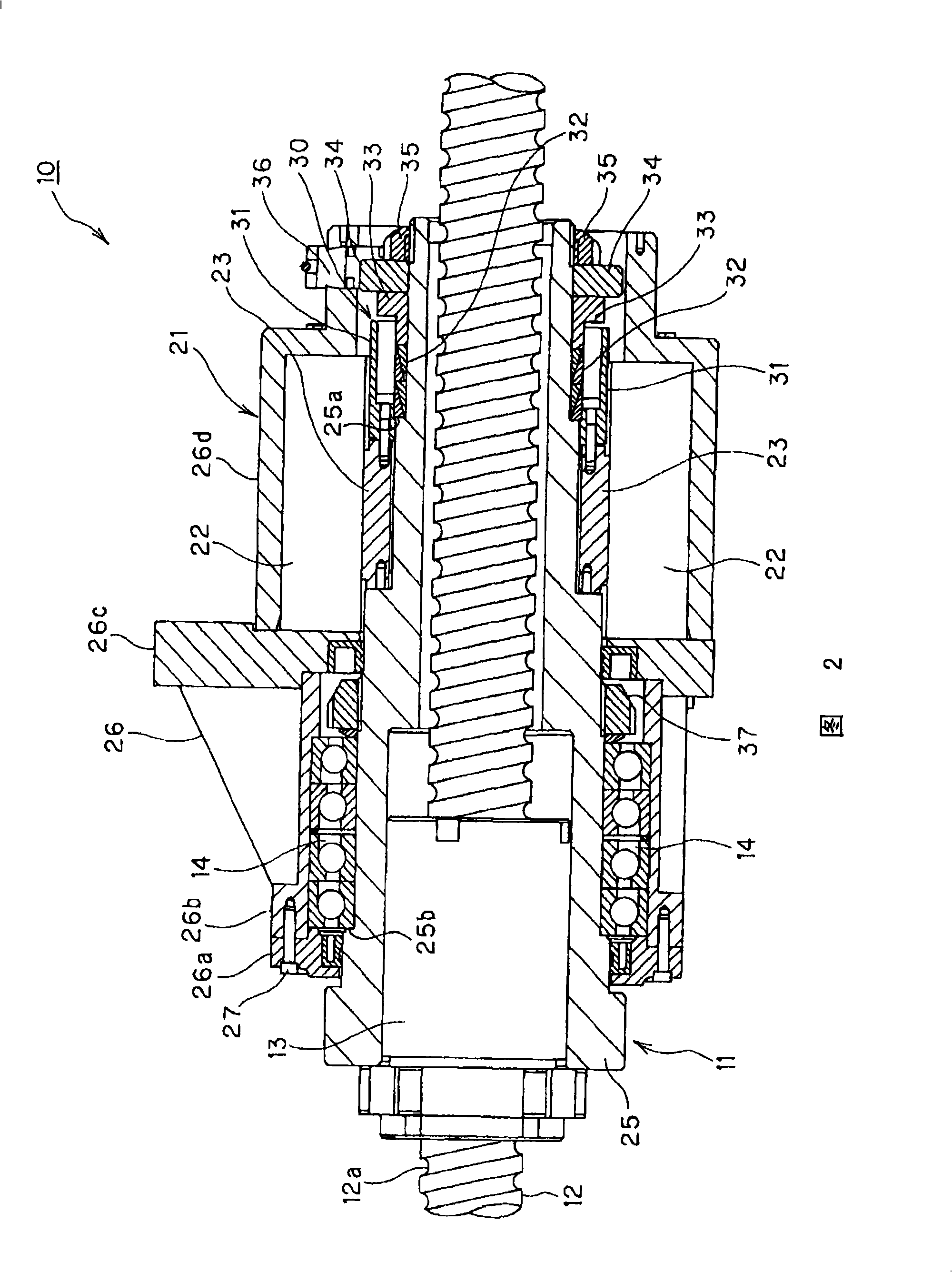

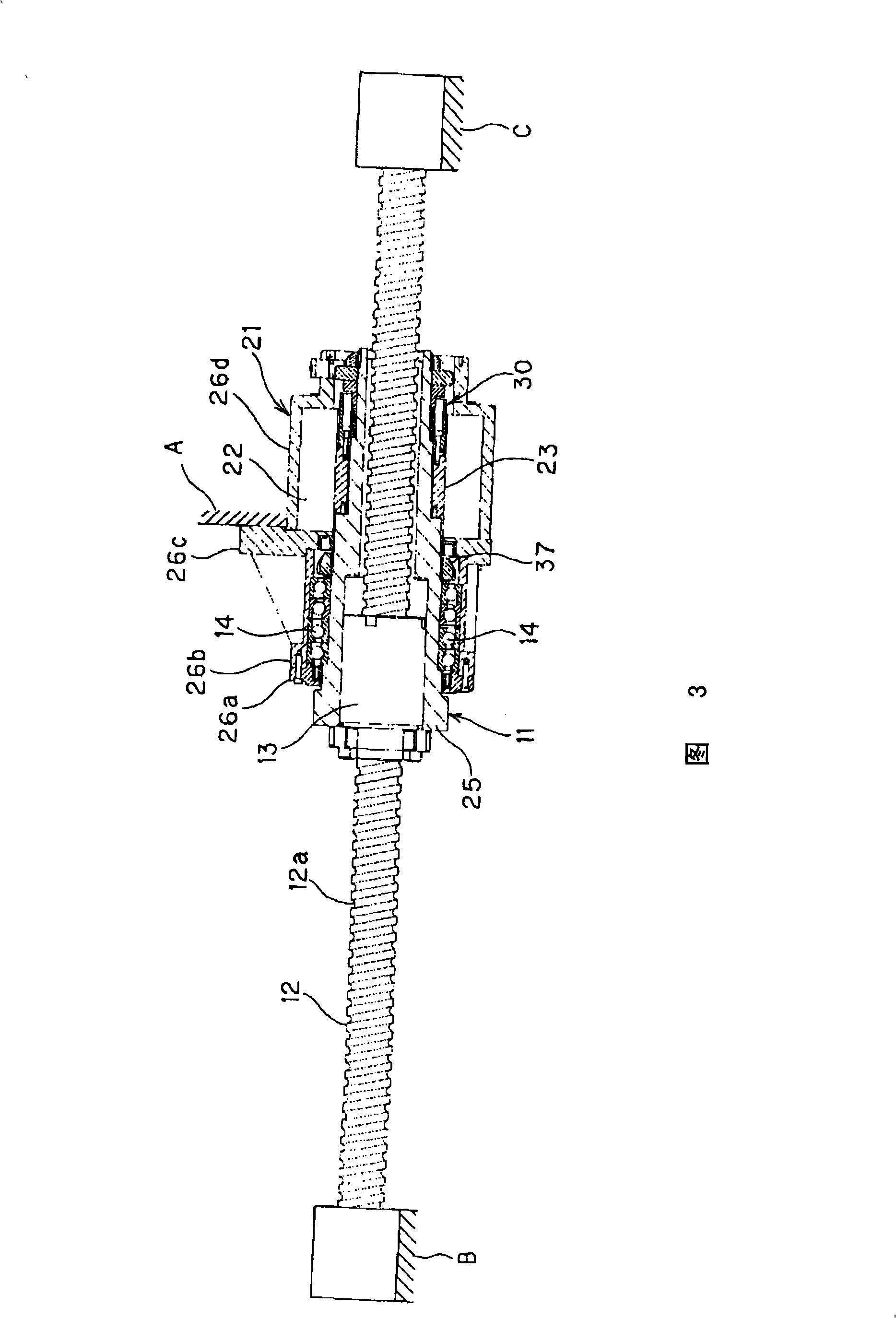

[0081] A specific usage example of the hollow motor drive device 10 according to the above-mentioned embodiment will be described with reference to FIG. 4 . Fig. 4 is an external perspective view showing an example of use of the hollow motor drive device of this embodiment.

[0082] In the hollow motor driving device 10 of the present embodiment, the flange portion 26c among the members constituting the casing 26 is removed, and the rectangular block 40 is provided on the outer periphery of the casing 26 . In addition, two linear guides 45 are provided below the block 40, the moving block 45a among the parts constituting the linear guide 45 is connected to the block 40, and the track guide 45b among the parts constituting the linear guide 45 Connect to the abutment part as the setting standard.

[0083] Moreover, if the hollow motor part 21 is operated with the threaded shaft 12 fixed, only the block body 40 moves in the axial direction, and if the hollow motor part 21 is ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com